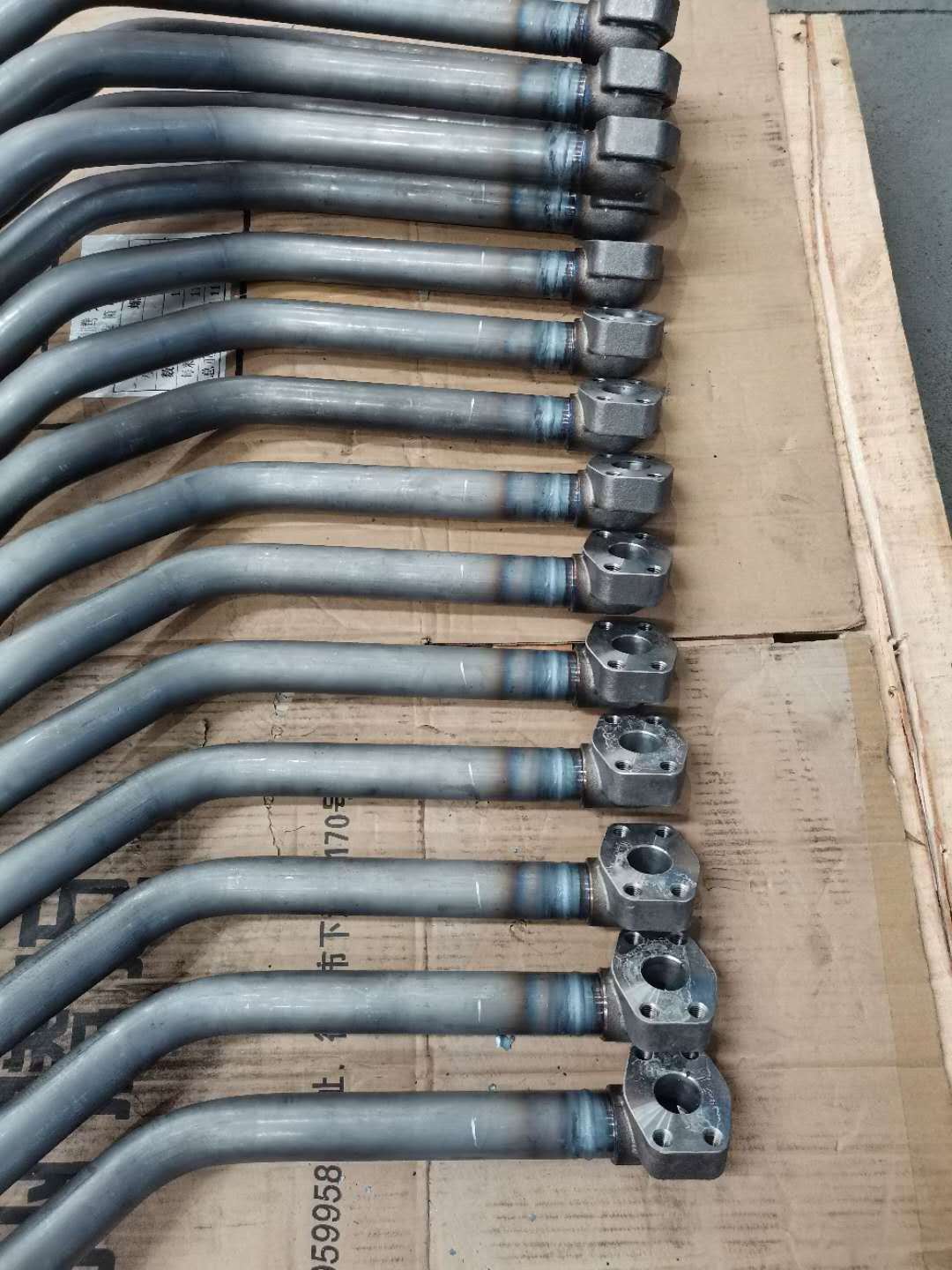

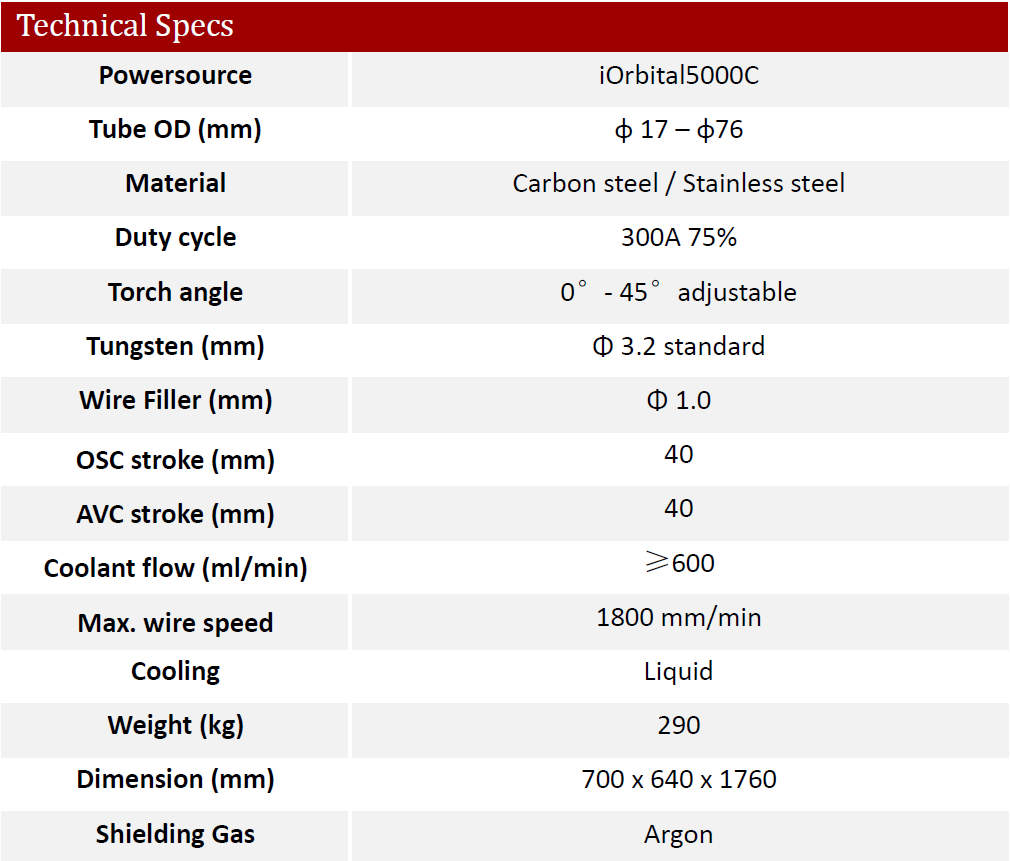

- Pipe OD

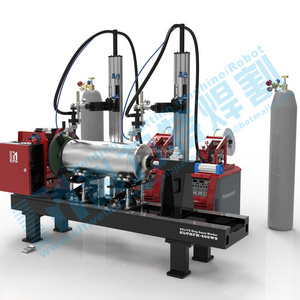

φ17mm - φ76mm

;

- Precise w

ire feeding function

;

-

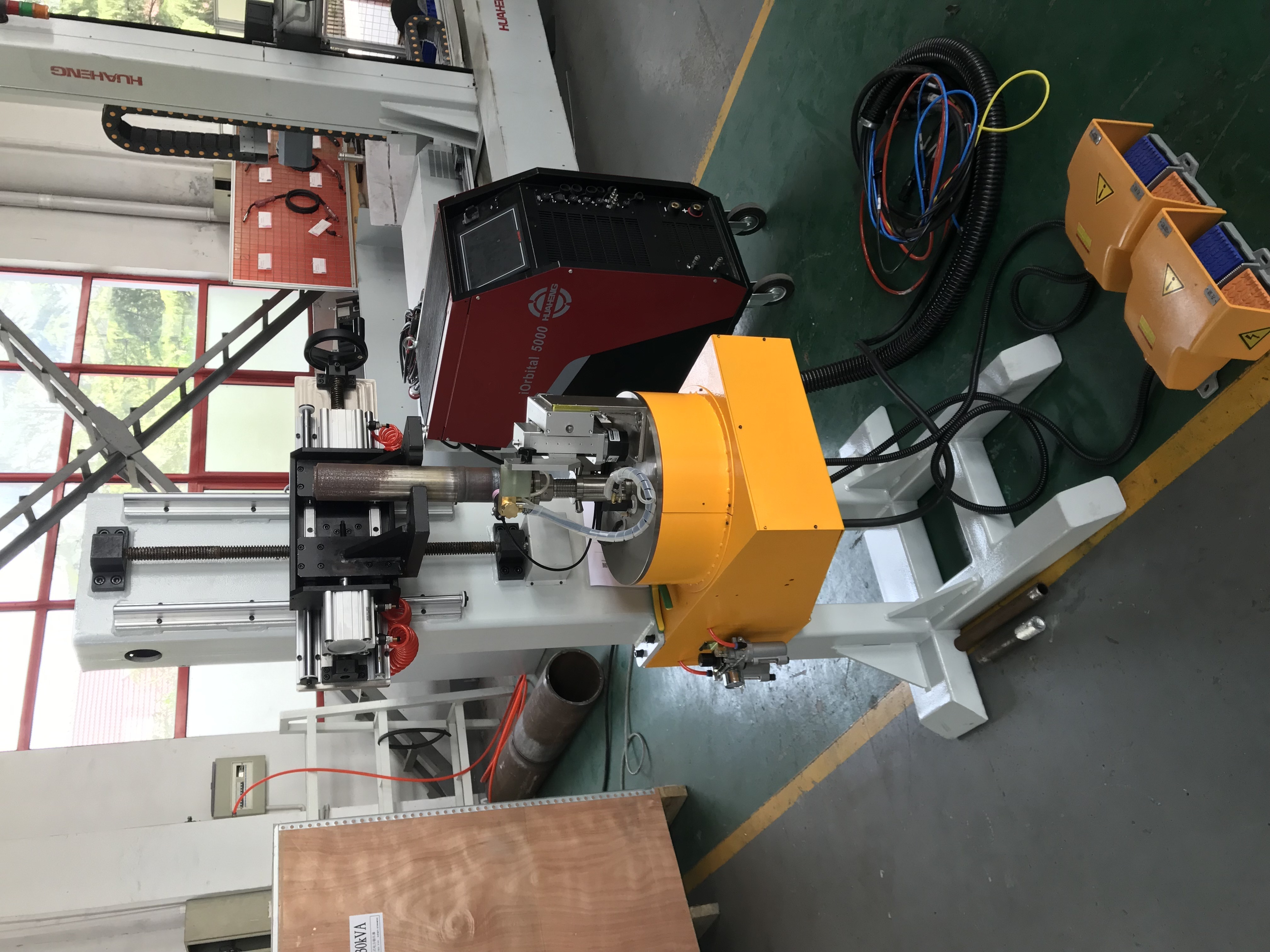

Motorized AVC & OSC function;

;

-

Liquid-cooling TIG torch;

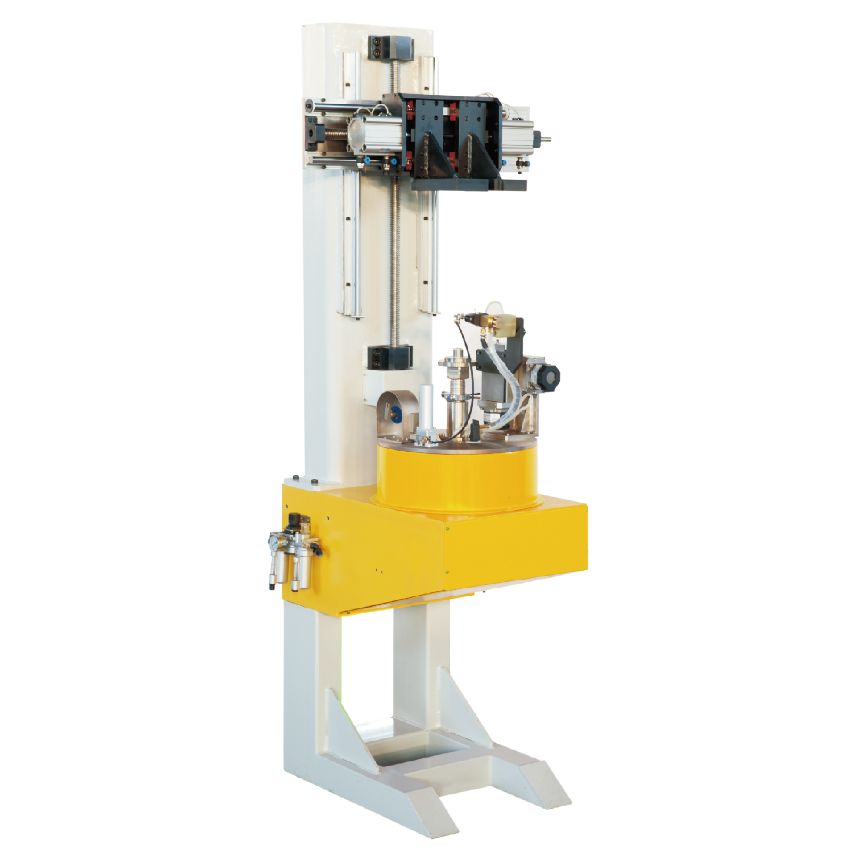

- Pneumatic clamping device;

-

Enhanced water cooling system;

-

Precision, stable and durable rotation

- Long life and durable using;

- Powersource

DSP and 4-layer PCB control;

- H

ardware/software modularization design;

-

Minimum current unit controlled at 0.1A;

- 10.4” Color Touch Screen.