Material: SUS316L and SUS304, soft tubes

Valve: Manual valves (can be customized to pneumatic valves)

Pure water pipe, tap-water pipe, drain pipe, steam pipe (customized) etc.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AILUSI

-

Voltage:

-

120V/220V/380V/440V

-

Power (kW):

-

16.5 kW

-

Function:

-

Mixing,Homogenizing,Emulsion

-

Mixing type:

-

Frame oar scrape stirrer

-

Structure:

-

Combined water and oil phase, main emulsion pot

-

Motor:

-

Siemens, Delta, Schneider, Delixi etc

-

Control:

-

Buttons/PLC control

-

Homogenizer:

-

High shearing rotor and stator homogenizing

-

Discharge:

-

Tilting discharge and bottom outlet

-

Certification:

-

ISO/CE

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Barrel Volume (L):

-

500L

-

Max. Loading Volume (L):

-

600 L

-

Range of Spindle Speed(r.p.m):

-

0 - 65 r.p.m

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AILUSI

-

Voltage:

-

120V/220V/380V/440V

-

Power (kW):

-

16.5 kW

-

Function:

-

Mixing,Homogenizing,Emulsion

-

Mixing type:

-

Frame oar scrape stirrer

-

Structure:

-

Combined water and oil phase, main emulsion pot

-

Motor:

-

Siemens, Delta, Schneider, Delixi etc

-

Control:

-

Buttons/PLC control

-

Homogenizer:

-

High shearing rotor and stator homogenizing

-

Discharge:

-

Tilting discharge and bottom outlet

-

Certification:

-

ISO/CE

-

After-sales Service Provided:

-

Video Technical Support

Video Description

AILUSI Machinery

Manufacturer of Cosmetic | Food | Daily Chemical industrial | GMP Standard

Lifting Small Vacuum Mixer:

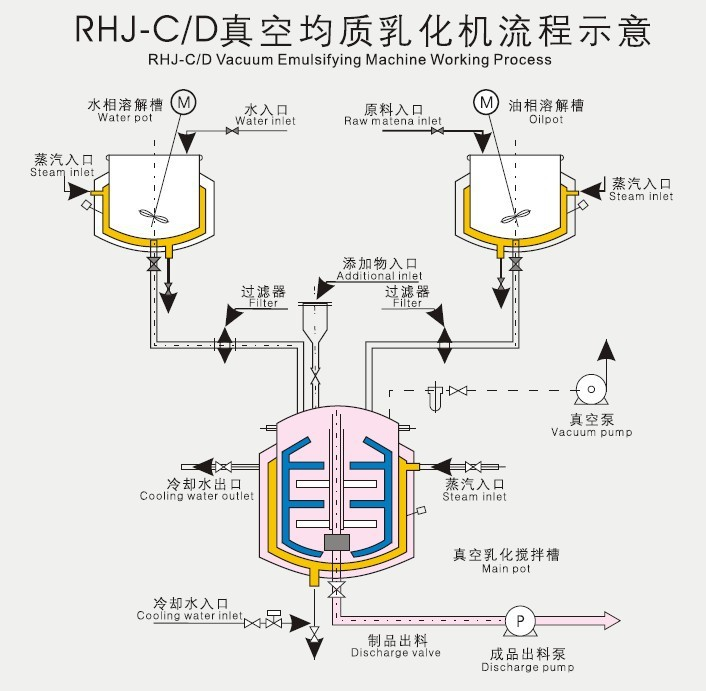

This machine is mainly consist of water pot, oil pot, emulsifying pot, vacuum system, lifting system, electric control system, operation platform, etc. (Systems and structure can be customized according to customer’s requirements .)

This kind of vacuum emulsifying cosmetic cream mixer makes use of the high shear emulsifier to distribute one or several phases to another continuous phase rapidly and evenly. It is mainly applied in such industries as daily skin care products (Body butters, face creams, hand lotions, detergents, etc.), biopharmaceutical industry, food industry, paint and ink, nanometer materials, petrochemical industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electrics and electronics, fine chemical industry, etc. The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

This machine is mainly consist of water pot, oil pot, emulsifying pot, vacuum system, lifting system, electric control system, operation platform, etc. (Systems and structure can be customized according to customer’s requirements .)

|

Item

|

|

vacuum emulsifying mixer

|

|

|

|||

|

Function

|

|

Mixing, Homogenizing, Emulsion

|

|

|

|||

|

Structure

|

|

Combined water and oil phase, main emulsion pot

|

|

|

|||

|

Material

|

|

SUS304&316L

|

|

|

|||

|

Homogenizer

|

|

High shearing rotor and stator homogenizing

|

|

|

|||

|

Mixer

|

|

Frame oar scrape stirrer |

|

|

|||

|

Discharge

|

|

Tilting discharge and bottom outlet

|

|

|

|||

|

Lifting system

|

|

Hydraulic lifting with safty protection

|

|

|

|||

|

Components

|

|

Siemens, Delta, Schneider, Delixi etc |

|

|

|||

|

Electric cabinet

|

|

Buttons/PLC control

|

|

|

|||

Material Sources

Details Images

Stainless Steel Sanitary Grade Pipes

Hot Searches