- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

lilin

-

Model Number:

-

LMD-400

-

Voltage:

-

220/380/415/440V

-

Dimension(L*W*H):

-

4580*1650*1850mm

-

Weight:

-

3000 KG

-

Max Speed:

-

500pcs/min

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

H.S.CODE:

-

8441200000

-

Control system:

-

Japan YASKAWA

-

Max production speed:

-

400 pcs/min

-

Usage:

-

Paper Forming Machine

-

Product name:

-

paper bag making machine

-

After Warranty Service:

-

Video technical support

-

After Warranty:

-

Online support

-

After-sales:

-

Video technical support

-

Provided:

-

Field maintenance and repair service

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

lilin

-

Model Number:

-

LMD-400

-

Voltage:

-

220/380/415/440V

-

Dimension(L*W*H):

-

4580*1650*1850mm

-

Weight:

-

3000 KG

-

Max Speed:

-

500pcs/min

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

H.S.CODE:

-

8441200000

-

Control system:

-

Japan YASKAWA

-

Max production speed:

-

400 pcs/min

-

Usage:

-

Paper Forming Machine

-

Product name:

-

paper bag making machine

-

After Warranty Service:

-

Video technical support

-

After Warranty:

-

Online support

-

After-sales:

-

Video technical support

-

Provided:

-

Field maintenance and repair service

Products Description

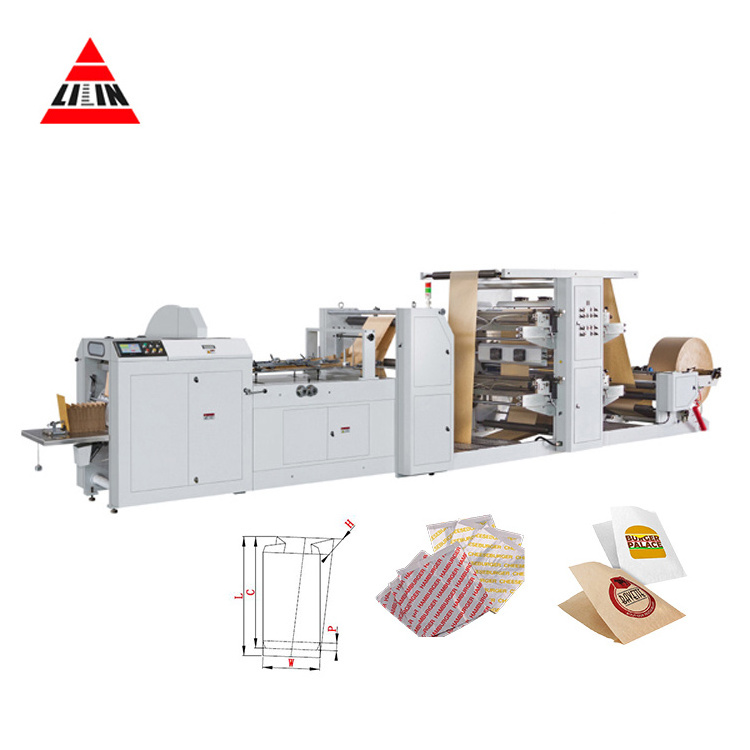

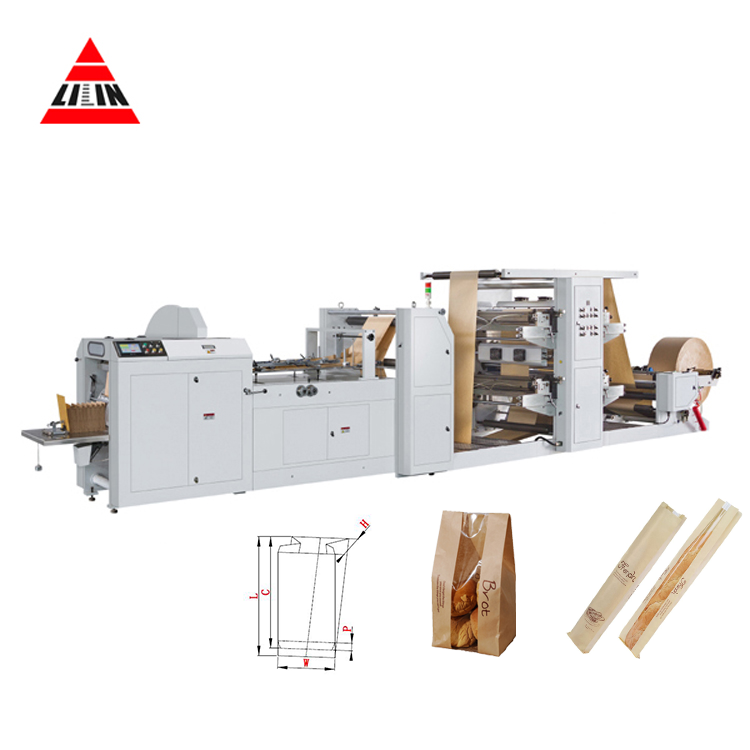

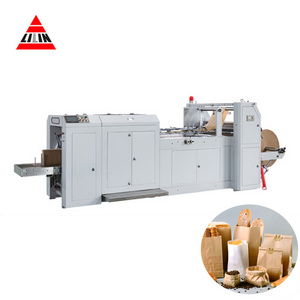

LMD-400 Fully Automatic Kraft Paper Bag Making Machine For V Bottom Bags

Introduction:

This Machine forming the paper bag in one process from roll paper, edge folding, tube

forming, cutting, gluing, bottom folding,bottom gluing and finishing bag Easy operation, low power consumption, high efficiency.

It is an ideal machine for producing food bags like bread bags, KFC bags and Mcdonald’s bags.

forming, cutting, gluing, bottom folding,bottom gluing and finishing bag Easy operation, low power consumption, high efficiency.

It is an ideal machine for producing food bags like bread bags, KFC bags and Mcdonald’s bags.

Features:

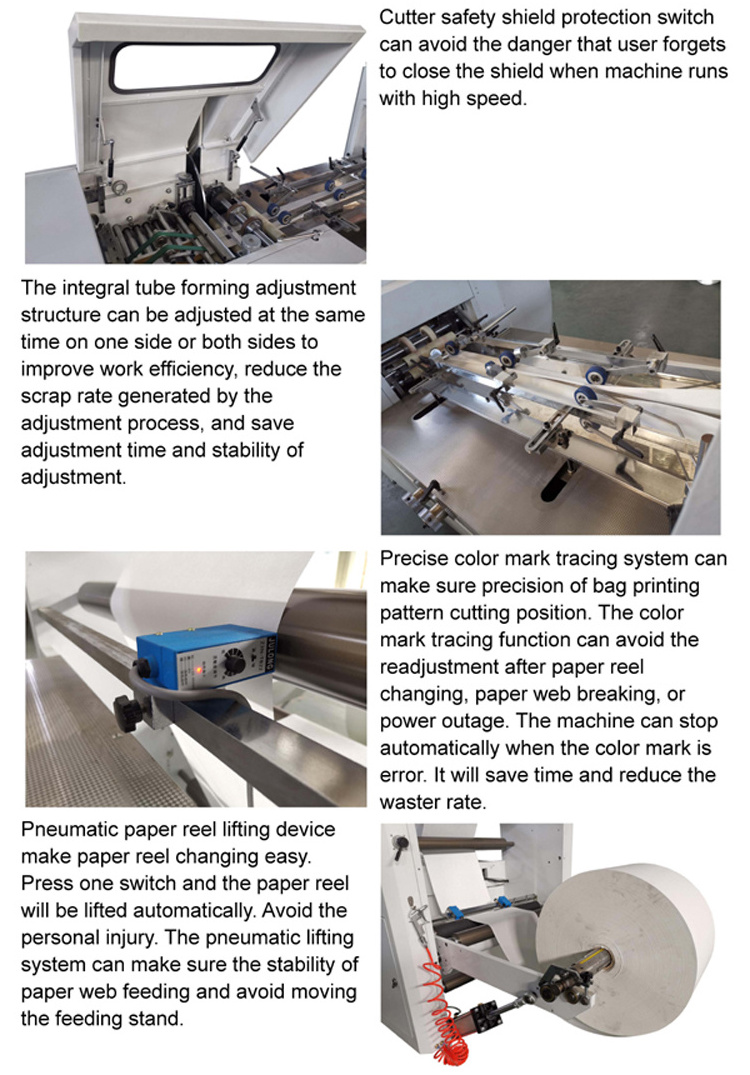

1.Controls bag length through the human-machine touch screen interface.

2. Adopt touch screen and PLC programmable control system, the work condition can be shown

real time.

3.The machine has automatic counting system. The user can set a number to count.

4 Equipped with an accurate photocell system for printed mark tracking.

5. Color mark error stopping system .

6.Double photoelectric sensor limit automatic correction control system.

7.Material lifting adopt pneumatic lift structure.

8.Automatic oil lubrication system.

2. Adopt touch screen and PLC programmable control system, the work condition can be shown

real time.

3.The machine has automatic counting system. The user can set a number to count.

4 Equipped with an accurate photocell system for printed mark tracking.

5. Color mark error stopping system .

6.Double photoelectric sensor limit automatic correction control system.

7.Material lifting adopt pneumatic lift structure.

8.Automatic oil lubrication system.

Product Paramenters

|

Type

|

LMD-400

|

|

Cutting Length(C)

|

150-460 mm

|

|

Bag Length (L)

|

140-450 mm

|

|

Bag Width (W)

|

70-280 mm

|

|

Gusset Thickness (H)

|

0-120 mm

|

|

Standard Flap (P)

|

12-20 mm

|

|

Max.Speed

|

500 pcs/min

|

|

Max. reel weight

|

400KG

|

|

Paper Roll Width

|

220-700 mm

|

|

Max.Roll Diameter

|

1100 mm

|

|

Reel Inner Diameter

|

76 mm

|

|

Paper specification

|

30-80 gsm

|

|

Web edge control system

|

Double photoelectric automatic correction control system

|

|

Web tension control system

|

automatic constant tension control system

|

|

Air pressure

|

≥ 0.12cmm, 0.4~1Mpa

|

|

Driven motor

|

Double servo motors

|

|

Electric

|

380V, 50Hz, 3 phase

|

|

Power

|

5 kw

|

|

Weight of Machine

|

2800 kg

|

|

Overall Dimension

|

4520×1550×1500 mm

|

Product packaging

FAQ

1.Are you trading company or manufacturer?

We are manufacturer, we have our own worker and factory.

2.How long has your factory been in this field?

In China, As one of the earliest manufacturers in paper bag machine, we have more than 10 years professional experience.

3.What types of machine do you have?

Commonly are paper bag machine V shape bottom or square bottom ,flexo printing machine,slitting machines according to clients'needs.

We are manufacturer, we have our own worker and factory.

2.How long has your factory been in this field?

In China, As one of the earliest manufacturers in paper bag machine, we have more than 10 years professional experience.

3.What types of machine do you have?

Commonly are paper bag machine V shape bottom or square bottom ,flexo printing machine,slitting machines according to clients'needs.

4.Where is your factory located? how can l visit there?

Our factory is located in ruian city.zhejiang province china.our local airport is Wenzhou Longwan Airportthe nearest international airport is shanghai Pudong Airport about 40 minutes by plane from shanghai (4 hours by train

5.Can i get some samples? how can l get it?

Yes,we can send you some free samples, but you need to bear the courier cost by DHL, TNT etc.

sincerely welcome all clients to visit us!

Our factory is located in ruian city.zhejiang province china.our local airport is Wenzhou Longwan Airportthe nearest international airport is shanghai Pudong Airport about 40 minutes by plane from shanghai (4 hours by train

5.Can i get some samples? how can l get it?

Yes,we can send you some free samples, but you need to bear the courier cost by DHL, TNT etc.

sincerely welcome all clients to visit us!

Hot Searches