- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

200 Series

-

Surface Finish:

-

2B

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Other Country

-

Brand Name:

-

Hong Ye

-

Model Number:

-

201 or 304

-

Application:

-

industry , construction, decoration

-

Outer Diameter:

-

1mm, 100-600mm or as required

-

Shape:

-

Round/Square/Rectangular/Oval

-

Surface:

-

Polishing

-

Thickness:

-

1--60mm or as required

-

Length:

-

customized

-

Keyword:

-

Stainless Steel Sipe

-

Package:

-

standard export package or required

-

Usage:

-

water/oil well drill

-

Payment terms:

-

30%TT Advance + 70% Balance

-

Certification:

-

ISO

Quick Details

-

Type:

-

Seamless ,welded

-

Steel Grade:

-

316L

-

Tolerance:

-

±1%

-

Grade:

-

200 Series

-

Surface Finish:

-

2B

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Other Country

-

Brand Name:

-

Hong Ye

-

Model Number:

-

201 or 304

-

Application:

-

industry , construction, decoration

-

Outer Diameter:

-

1mm, 100-600mm or as required

-

Shape:

-

Round/Square/Rectangular/Oval

-

Surface:

-

Polishing

-

Thickness:

-

1--60mm or as required

-

Length:

-

customized

-

Keyword:

-

Stainless Steel Sipe

-

Package:

-

standard export package or required

-

Usage:

-

water/oil well drill

-

Payment terms:

-

30%TT Advance + 70% Balance

-

Certification:

-

ISO

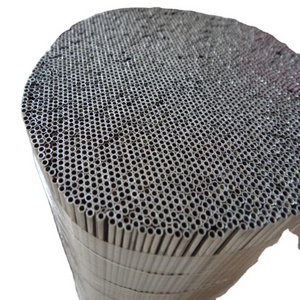

| Name | 201 304 904 stainless steel pipe |

| Standard |

ASME SA213/ASTM A213, ASTM A269/ASME SA269, ASME SA312/ASTM A312 EN10216-5,EN10305-1, EN10217-5, DIN 17175, DIN 2448, DIN 6258 JIS G3463, JIS G3462, JIS G3455, JIS G3459 etc. |

| Material |

TP304, TP304L, TP304H, SUS201,TP314, TP316, TP316L, TP316LN, TP321, TP321H, TP310, TP310S, TP317, TP317L, TP347, TP347H, 904L, 2205, 2520, 2207 |

| Type | Seamless / Welded |

| O.D | 6mm - 610mm or customized |

| W.T | 0.5mm - 50mm or customized |

| Length | 5.8m, 6m, 1-12m or as percustomer required |

| Technique | Cold Finished (Cold Drawing and Cold Rolling), Hot Finished (Hot Extrusion) |

| Surface Treatment | Pickled,Passivation,Inside & Outside Mechanical Polishing, BA, Electropolishing (EP) |

| Heat Treatment Condition | Solution Annealing and water rapid quenched, Bright Annealing,Stess Relieving Heat Treatment for U tubes |

| Test Requirement |

Eddy Current Test, Hydrostatic Test, UT, Penetrant Test, Air underwater pressure Test,

PMI Test, Spectro Test, Intergranular Corrosion Test, Sharpy Impact Test, Hardness Test, Tension Test (Elongation, Yield Strength,Tensile Strength), Flarring Test etc. |

| Application | Gas and Fluid Transportation; Mechanical Pipline; Engineering Projects; Petrochemical industry; Power Station, Heat Exchanger, Condenser, Boiler, Evaporator, Superheater etc. |

| Capacity | 10,000 tons/year |

| Package | In bundles pacckages, plywood cases, wooden cases with water-proof package, etc. |

| Trade Terms | FOB, CIF, CFR, EXW, etc. |

| Payment Terms | T/T, L/C |

Contaniers:

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

40ft HC:12032mm(Lengh)x2352mm(Width)x2698mm(High)