- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HaoRui

-

Product name:

-

Precision ceramic parts

-

Color:

-

White/Ivory

-

Shape:

-

Customized

-

Dimension:

-

Customized

-

Quality control:

-

100% Inspection

-

Feature:

-

High hardness, High strength, High temperacture

-

Max Working Temperature:

-

1600℃

-

Gas permeability:

-

0

-

Water Absorption:

-

0

-

MOQ:

-

1 Pcs

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

AL2O3-048B

-

Brand Name:

-

HaoRui

-

Product name:

-

Precision ceramic parts

-

Color:

-

White/Ivory

-

Shape:

-

Customized

-

Dimension:

-

Customized

-

Quality control:

-

100% Inspection

-

Feature:

-

High hardness, High strength, High temperacture

-

Max Working Temperature:

-

1600℃

-

Gas permeability:

-

0

-

Water Absorption:

-

0

-

MOQ:

-

1 Pcs

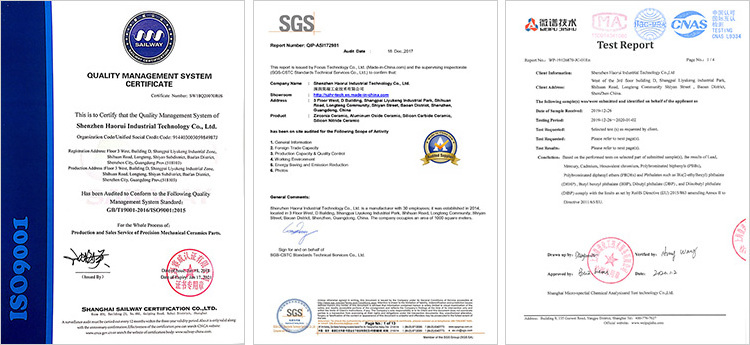

ABOUT SHENZHEN HAORUI

Welcome to Shenzhen Haorui Industrial Technology Co., Ltd. We hope our products will interest you!

Shenzhen Haorui Industrial Technology Co., Ltd. was established in June 2006. It is an enterprise specializing in R&D,

manufacturing and sales of engineering ceramics. After more than ten years of development, we have accumulated rich industry experience and trained a group of professional technicians. We have a complete production process and quality management system, as well as a complete set of precision processing equipment and testing equipment.

Our engineering ceramic products are widely used in precision machinery manufacturing, microelectronics, semiconductors, aerospace, biomedicine, optical fiber communications, testing and inspection, solar photovoltaic and other fields. With the continuous innovation of technology and the continuous expansion of production capacity, we are committed to spreading high-quality engineering ceramics to every corner of the industry, improving human productivity, and contributing our own strength to social development.

Today, Haorui has more than 1,000 customers worldwide and has cooperated with more than 30 universities and scientific research institutions. We enjoy a high reputation and good reputation in the same industry, and the company's overall strength is in a leading position in the industry.

MECHANICAL&INDUSTRIAL CERAMICS

Due to its excellent wear resistance, corrosion resistance, high temperature resistance, low density and other properties, ceramic materials are recognized as one of the vibrant new materials in the 21st century. It is listed as the four contemporary engineering materials alongside metal materials, polymer materials, and composite materials.

According to performance and use, ceramic materials are divided into traditional ceramics and advanced ceramics. Advanced ceramics and traditional ceramics are significantly different in terms of raw materials, structure, and preparation techniques. The performance of the two is also very different. Advanced ceramic materials far surpass modern high-quality alloys and polymer materials in certain properties. Therefore, it has a wide range of application value and potential in various industrial fields, such as petroleum, chemical, steel, electronics, textile and automobile industries, as well as cutting-edge technology fields such as aerospace, nuclear industry and military industry.

Material Characteristics

These properties were measured on test samples.The values are typical material properties and may varyaccording to product configuration,geometry and manufacturing process.Please contact customer service for more data.

|

Property

|

Item

|

99%

Alumina

|

99.8%

Alumina

|

Zirconia Ceramics

|

Silicon Nitride

|

Silicon Carbide

|

Unit

|

|

Mechanical Characteristics

|

Color

|

light yellow

|

White

|

Ivory

|

Black

Grey

|

Black

|

|

|

|

Bulk Density

|

3.85

|

3.93

|

6.02

|

3.2

|

3.16

|

g/cm

3

|

|

|

Water Absorption

|

0

|

0

|

0

|

0

|

0

|

%

|

|

|

Bending Strength

|

310

|

370

|

800

|

750

|

450

|

MPa

|

|

|

Compressive Trength

|

2,400

|

2500

|

3000

|

3800

|

3900

|

MPa

|

|

|

Elastic Modulus

|

340

|

390

|

200

|

290

|

420

|

GPa

|

|

|

Fracture Toughness

|

3~4

|

4

|

8

|

7

|

3.5

|

MPa m

1/2

|

|

|

Weber Coefficient

|

12

|

12

|

15

|

15

|

-

|

m

|

|

|

Vickers Hardness

|

1,600

|

1850

|

1200

|

1700

|

2800

|

HV 0.5

|

|

Thermal Characterics

|

Coefficient of Line Thermal

Expansion

|

7~8

|

7~8

|

10

|

2

|

3.7

|

10

-6

K

-1

|

|

|

Thermal Conductivity

|

29

|

32

|

3

|

20

|

160

|

W/mK

|

|

|

Thermal Shock Resistance

(Put in Water)

|

200

|

280

|

300

|

750

|

-

|

ΔT °C

|

|

|

Max Working Temperature

|

1,600

|

1700

|

1000

|

1300

|

1950

|

°C

|

|

Electrical Characteristics

|

Volume Resistance At 20°C

|

>10

14

|

>10

14

|

>10

13

|

>10

14

|

-

|

Ωcm

|

|

|

Dielectric Strength

|

15×10

6

|

15×10

6

|

11×10

6

|

10×10

6

|

-

|

V/m

|

|

|

Dielectric Constant

|

10

|

10

|

33

|

-

|

-

|

εr

|

|

|

One MHZ Dielectric Loss Angle

at 20°C

|

0.0002

|

0.0001

|

0.0016

|

-

|

-

|

tanδ

|

|

Chemical Characteristics

|

Nitric Acid (60%) 90°C

|

0.1

|

0.05

|

≒0.00

|

1

|

≒0.00

|

24H WT Loss mg/cm

2

|

|

|

Sulphuric Acid (95%) 95°C

|

0.34

|

0.22

|

0.04

|

≒0.00

|

≒0.00

|

|

|

|

Caustic Soda (30%) 80°C

|

0.95

|

0.04

|

0.08

|

0.2

|

≒0.00

|

|

PRECISION SHAPING AND MACHINING

With unique ceramic precision machining technology, formed material is cut and lapped after sintering to required shapes. These products are used for their unrivaled performance in OA sliding parts as general structural members, precision jigs and tools, in wear and chemical resistant sliding parts and also in electromagnetic fields and chemical solutions.

|

Process range

|

|

|

|

|

|

|||||

|

Inside Diameter

|

≥0.2mm

|

Length

|

≤750mm

|

Internal thread

|

≥2mm

|

|||||

|

Outside Diameter

|

≤400mm

|

Thickness

|

≤400mm

|

External thread

|

≤400mm

|

|||||

|

Machining accuracy

|

0.001

|

Straightness

|

|

Roughness

|

|

|||||

|

roundness

|

0.002mm

|

Parallelism

|

0.003mm

|

Verticality

|

0.005mm

|

|||||

|

concentricity

|

0.002mm

|

Flatnes

|

0.002mm

|

Straightness

|

0.005mm

|

|||||

|

clearance fit

|

0.003mm

|

tolerance of dimension

|

0.001mm

|

surface roughness

|

Ra0.1

|

|||||

Ceramic shaft and sleeve

Plane processing

Ceramic micro hole machining

Ceramic processing thread

Ceramic complex shaped parts

Ceramic parts polishing

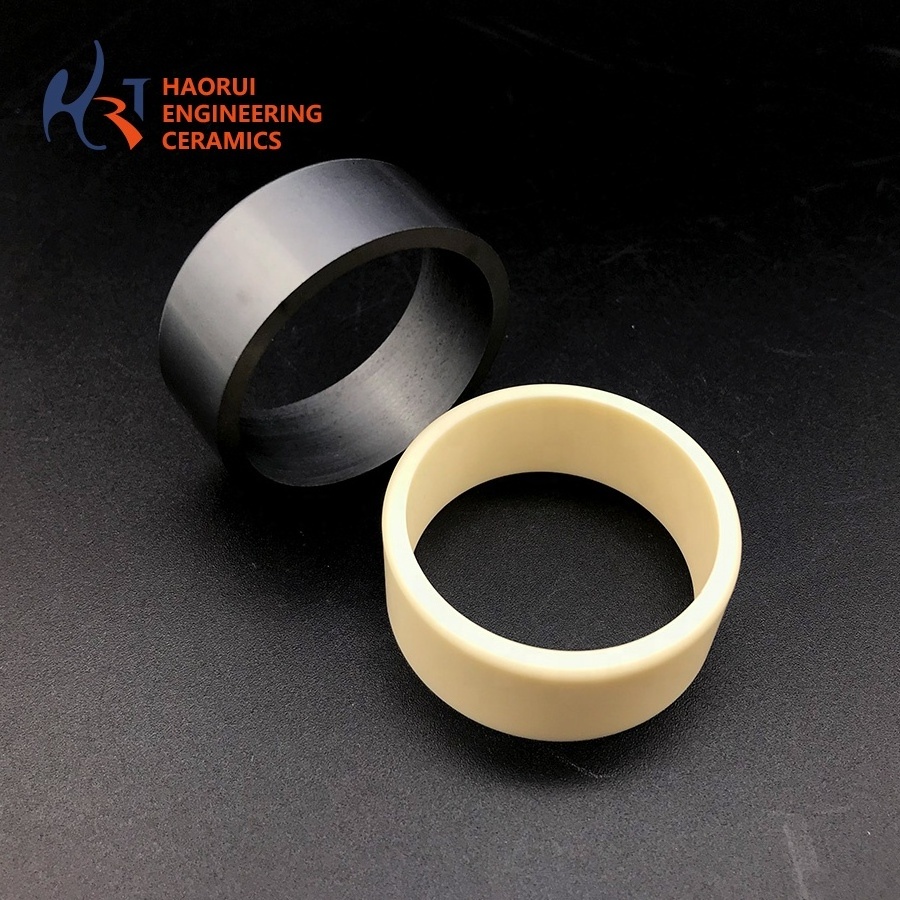

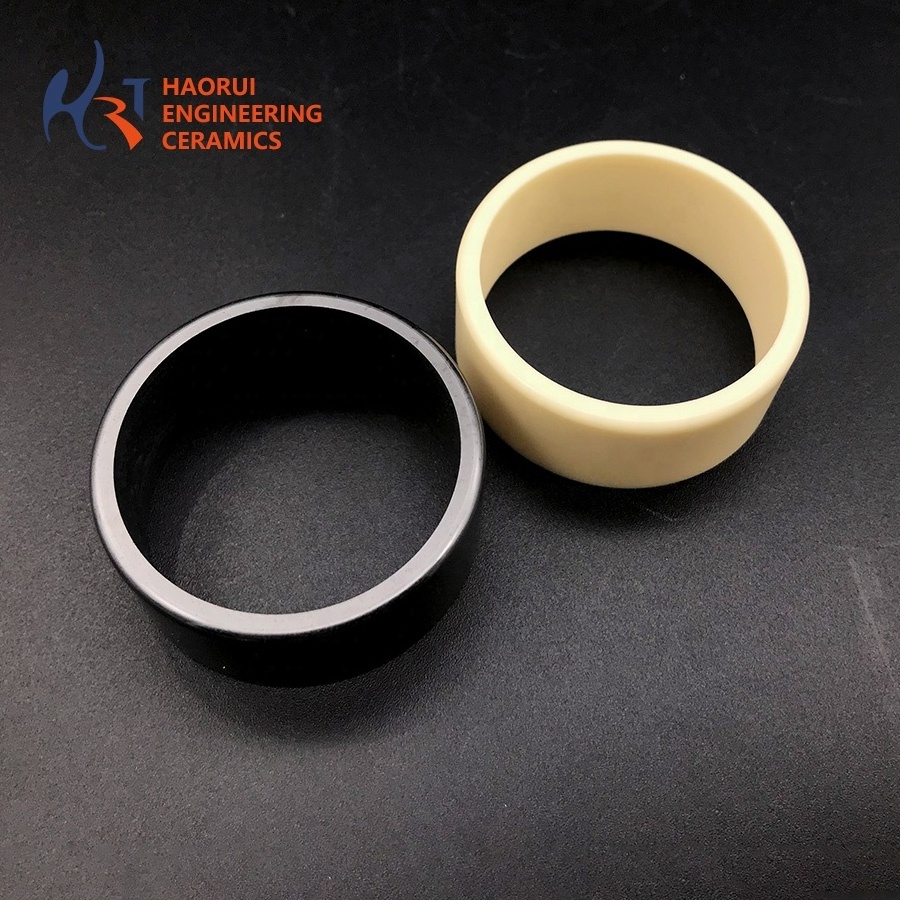

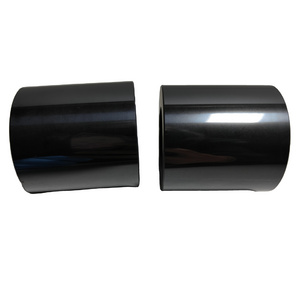

PRODUCT IMAGE

PACKAGING&SHIPPING

FAQ

Q: Are you a factory or a trading company

A: We are a professional manufacturer of ceramic parts. we are factory.

Q:Do you only supply standard parts or can customized parts according to our drawing?

A: All parts can be customized according to you drawings and will meeting your requirements perfectly.

Q:Can the price be negotiated

A: Of course, we will consider discounts for large-volume orders.

Q:Can you guarantee the product?

A: Yes, we promise to provide quality assurance for all products, inspect according to your drawings and issue an inspection report. If you are not satisfied with our product quality or service, please feel free to give us feedback.

Q:Can I visit your factory?

A: Of course, welcome your arrival, please contact us in advance and make an appointment.

Q:Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q.What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question,pls feel free to contact us as below.

CONTACT US

Hot Searches