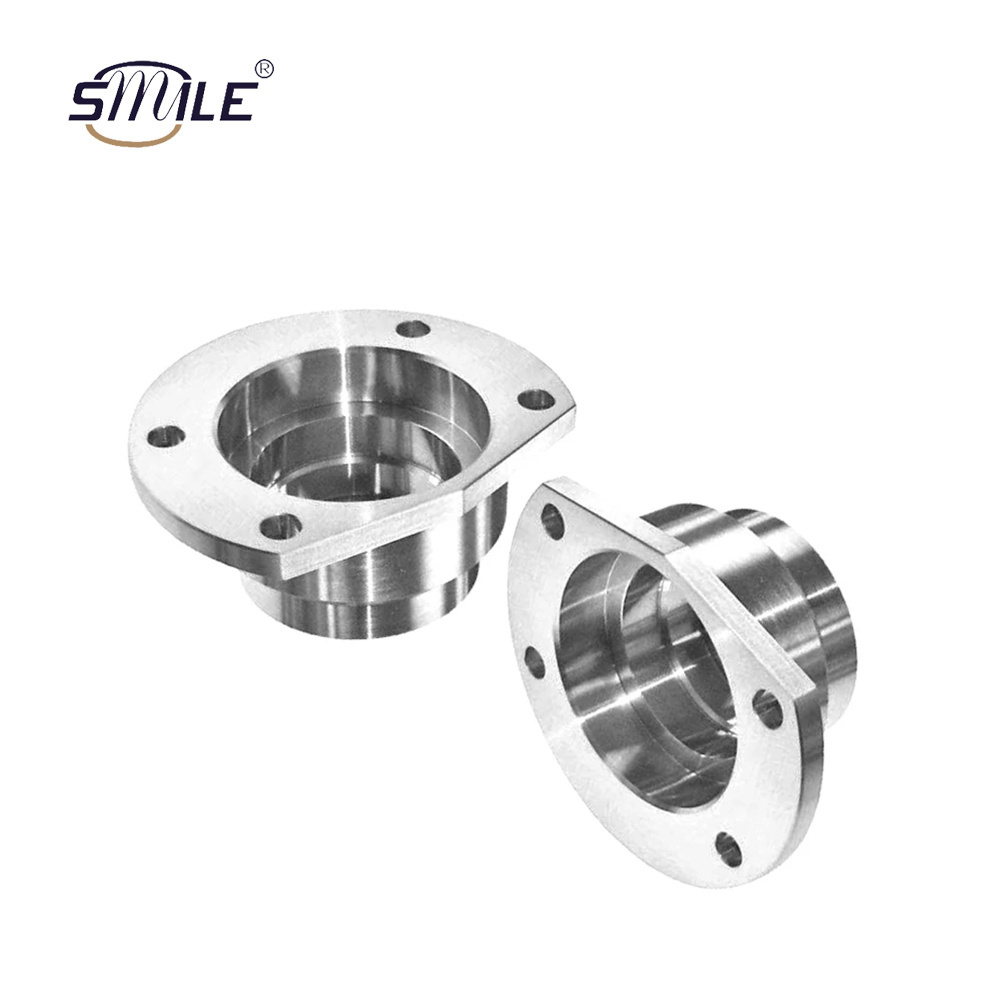

CNC metal machining

is an automated manufacturing process whereby the factory metal machining tool is operated by pre-programmed software. The acronym CNC comes from the term "computer numerical control."

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LNSB-01A

-

Brand Name:

-

SMILE

-

Material:

-

stainless steel 304/316,aluminum,brass

-

Service:

-

Customized OEM

-

Surface treatment:

-

Sand blowing, sanding, wire drawing, polishing

-

Color:

-

Customized Color

-

Keyword:

-

Oem Cnc Parts

-

Thickness:

-

0.8mm~ 40.0mm

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Package:

-

Bubble Bag+ Carton+ Wooden Box

-

Quality Control:

-

ISO/TS9001:2015

-

MOQ:

-

10pcs

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Stainless steel

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

LNSB-01A

-

Brand Name:

-

SMILE

-

Material:

-

stainless steel 304/316,aluminum,brass

-

Service:

-

Customized OEM

-

Surface treatment:

-

Sand blowing, sanding, wire drawing, polishing

-

Color:

-

Customized Color

-

Keyword:

-

Oem Cnc Parts

-

Thickness:

-

0.8mm~ 40.0mm

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Package:

-

Bubble Bag+ Carton+ Wooden Box

-

Quality Control:

-

ISO/TS9001:2015

-

MOQ:

-

10pcs

|

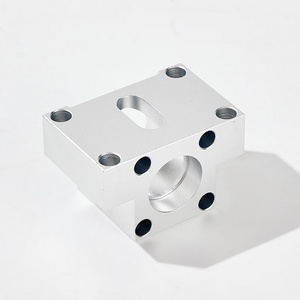

CNC Machining or Not

|

Customizable Cnc Machining

|

|

Usage

|

Customizable Semiconductor parts,Auto parts, electric car, motorcycle, bicycle parts accessories, custom screws Hospital instrumentation parts precision sheet

metal precision machining |

|

Type

|

Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning,Wire EDM

|

|

Material Capabilities

|

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

|

|

Surface treatment

|

Anodizing ,Polishing, general/hard/color oxidation, surface chamfering,

tempering,Brushing, Laser engraving , Zinc/Nickl/Chrome/Titanium Plating etc.

|

|

Tolerance

|

0.01-0.05mm

|

|

Drawing Format

|

IGS , STEP ,PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF, JPG

|

|

Our Service

|

Customizable OEM&ODM CNC machining,as per customer's requirement

|

|

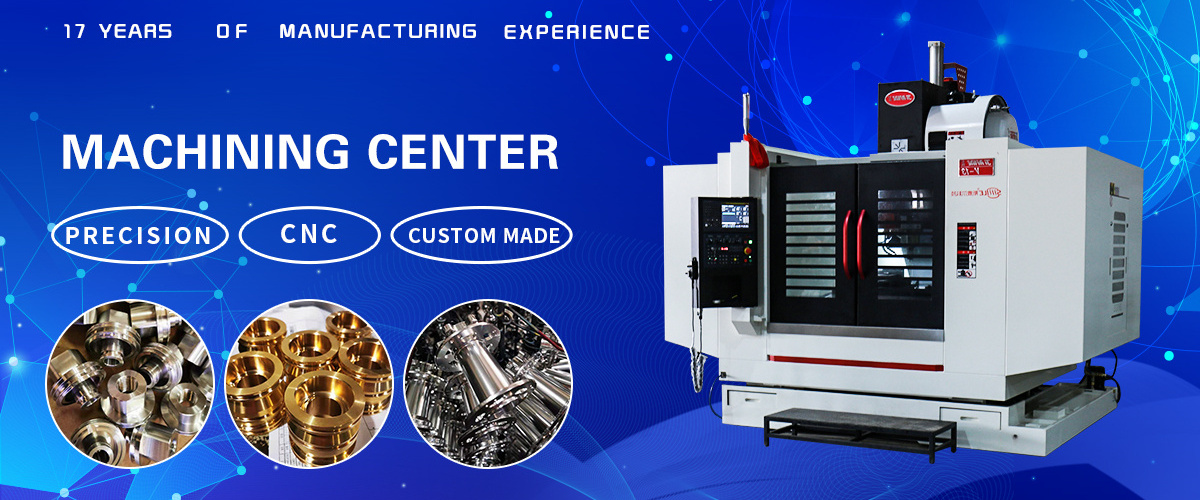

Equipment

|

CNC Machining Center,CNC lathe,CNC turning,milling

|

|

Our Advantage

|

1) 24 hours online service & Quickly Quotation/ fast Delivery.

2) 100% QC quality inspection before delivery, and can provide quality inspection form.

3) 18 years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. 4) We are good at Precision CNC long Rod axle and CNC runing and CNC milling services. |

METAL CNC MACHINING SERVICES

LiaoNing SMILE has provided precision CNC machining services since 2005. Customers have come to know LiaoNing SMILE as an

ISO 9001: 2015 Certified

metal machine shop that provides exceptional quality at competitive prices. Need a quality machine shop? Whether your need is metal machining, or machining finishing, LiaoNing SMILE offers accurate precision machining backed by on-site quality inspection services. Our best-in-class CNC machining services includes CNC Milling and CNC Turning. Additional machine shop services include Surface Grinding, Assembly and Finishing.

In order to better serve our customers, our company has built a class 10,000 clean workshop.SMILE has enough factory strength and excellent service attitude to ensure product quality.

Related Products

Completely standard export wooden boxes and cartons (packed in pearl foam and foam board).

- The logo, model name and details of the model, such as number of pieces and size, can be printed on the wooden box or carton.

- Possibility to print a sketch of the product on the outside of the packaging;

- Internal protective packaging, foam material, moisture-proof plastic, etc.;

- We can produce packaging to your bespoke design.

Company

Da Henan Plant

The main production plant of sheet metal products, non-standard sheet metal products customization, can produce all kinds of sheet metal parts, cabinets, case shell, intelligent integrated machine shell, etc.

Hunnan Plant

The main production area for machined parts and equipment shells and frames, with a large machining center and a class 10,000 clean workshop to meet customer needs

Factory Equipment

Why Choose Us

FAQ

1.Why is there a difference between the actual price and the marked price?

Our price is only the price of a standard size product, if you need other sizes or styles, then there will be price differences in materials and processes

2.Why are your prices more expensive than other suppliers?

We use plates of sufficient size with only 0.1-0.2mm down difference

3.Why is shipping so expensive?

Shipping costs are not under our control, they are determined by the freight company, but we can apply for a discount on your payment based on the quantity of your goods

4.Can you customize packaging and logos and how do you charge for them?

We can customize the packaging and logo according to your idea, the price will be charged according to your volume, if the volume is small, you need to charge, the volume is large, free of charge.

5.Can I keep an eye on the progress of my shipment?

Of course you can, we have professional staff to follow the whole process and interface with you

6.Can I send you samples or drawings that you can use as a basis for production?

Of course, we support CAD/PDF/SOLIDWORKS and other formats of drawings

Hot Searches