- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1 KG

-

Product name:

-

50W CW high power diode side-pumped Nd:YAG yag laser

-

Keywords:

-

laser diode module 50w

-

Output power:

-

50W

-

Wavelength:

-

1064mm

-

Application:

-

Engraving. Cutting

-

Model No.:

-

GN50

-

Lifetime:

-

10000 hours

-

Laser type:

-

laser diode module 50w

-

Brand:

-

laser diode module 50w

Quick Details

-

Place of Origin:

-

China, Beijing

-

Warranty:

-

12 months, 12months

-

Spare Parts Type:

-

Laser Chamber

-

Weight (KG):

-

1 KG

-

Product name:

-

50W CW high power diode side-pumped Nd:YAG yag laser

-

Keywords:

-

laser diode module 50w

-

Output power:

-

50W

-

Wavelength:

-

1064mm

-

Application:

-

Engraving. Cutting

-

Model No.:

-

GN50

-

Lifetime:

-

10000 hours

-

Laser type:

-

laser diode module 50w

-

Brand:

-

laser diode module 50w

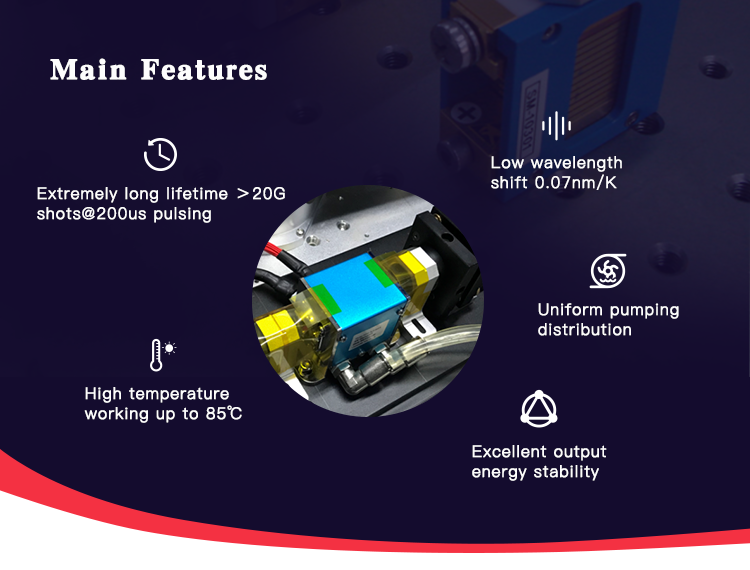

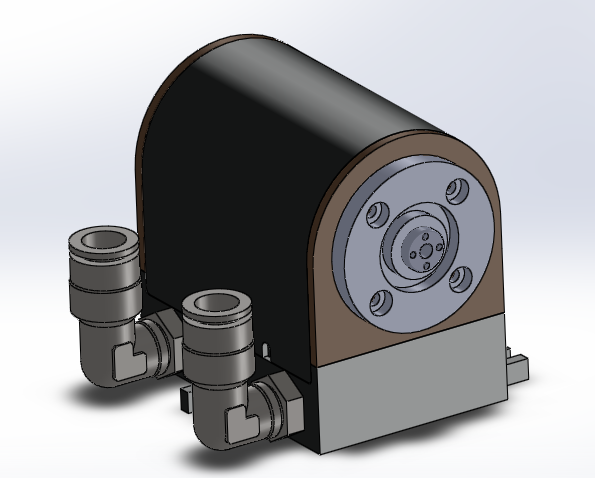

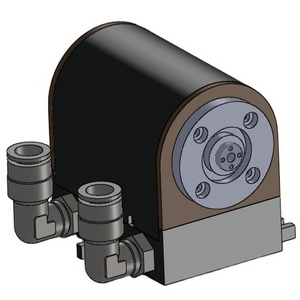

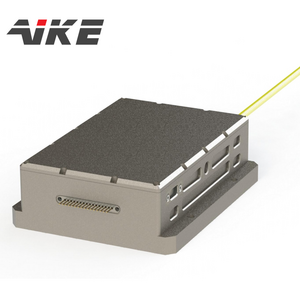

50W CW high power diode side-pumped Nd:YAG yag laser

1.Product Introduction

GN50 is 50W CW high power diode side-pumped Nd:YAG laser module. It comes with

excellent beam quality and long life time. It is widely used for marking, engraving, welding, cutting and etc.

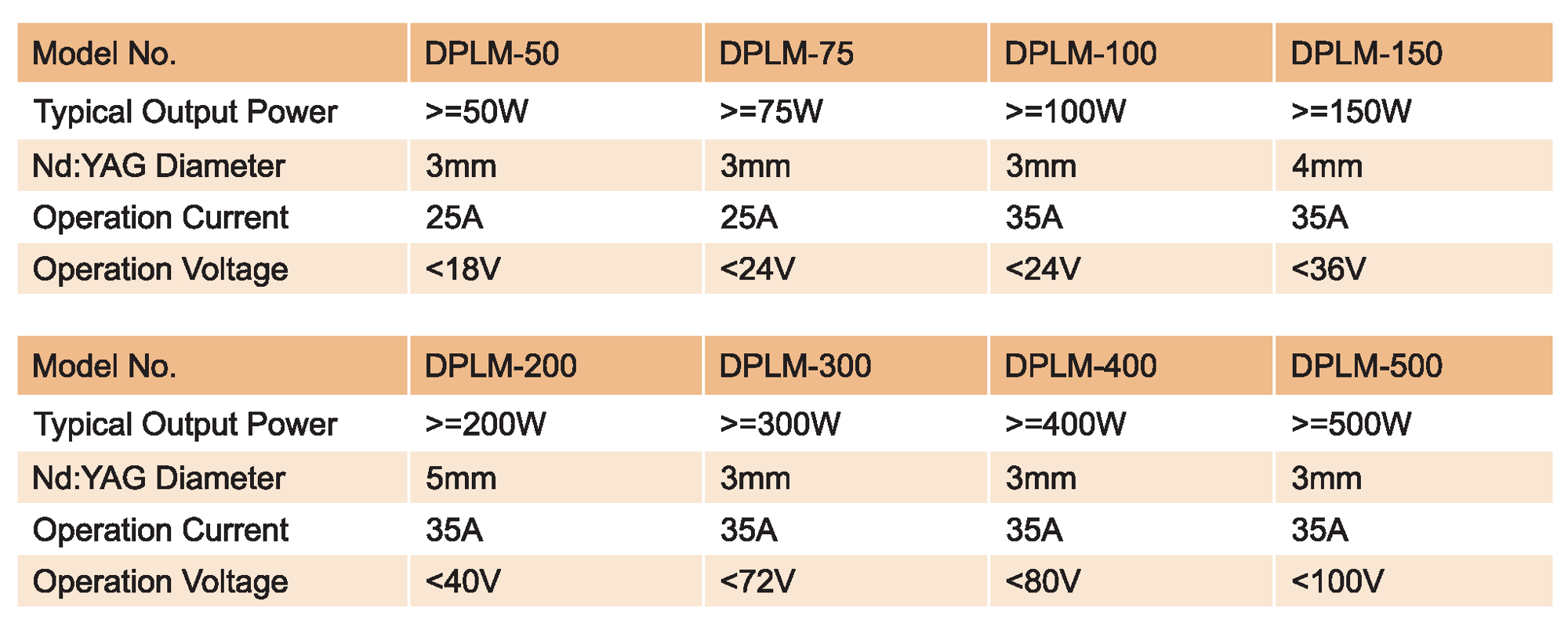

Product Specifications

Note:

1. Minimum 1064nm multi-mode output in a short cavity (300 mm, Plano-Plano Cavity, OC T=20%).

2. Expected life time is around 10,000 hours. Warranty: 13 months after delivery.

3. The Nd:YAG rod can be customized with different diameter, length & doping level.

4. Other DPSS laser modules can be customized according to specific requirements.

5. QCW / Pulsed modules available.

Operation & Warranty Manuals

1.

Installation

Please take following steps to start the DPSS laser module.

1) Position the laser module on the optic rail and make sure that the beam output is in parallel. Position the high

reflection mirror (HR, R>99.8% at 1064nm) and output coupler (OC, R=80% @ 1064nm) and adjust them with

pilot beam (He-Ne laser or well-collimated red diode laser) into an optical resonator. The distance between HR

and OC can be adjusted by users and other components can be inserted (such as Q-switch, aperture or etc).

2) Connect the water inlet & outlet with water pipes from chiller and make sure the water flow is not jammed.

Connect the protection wire from the water chiller to the laser diode driver’s interlock.

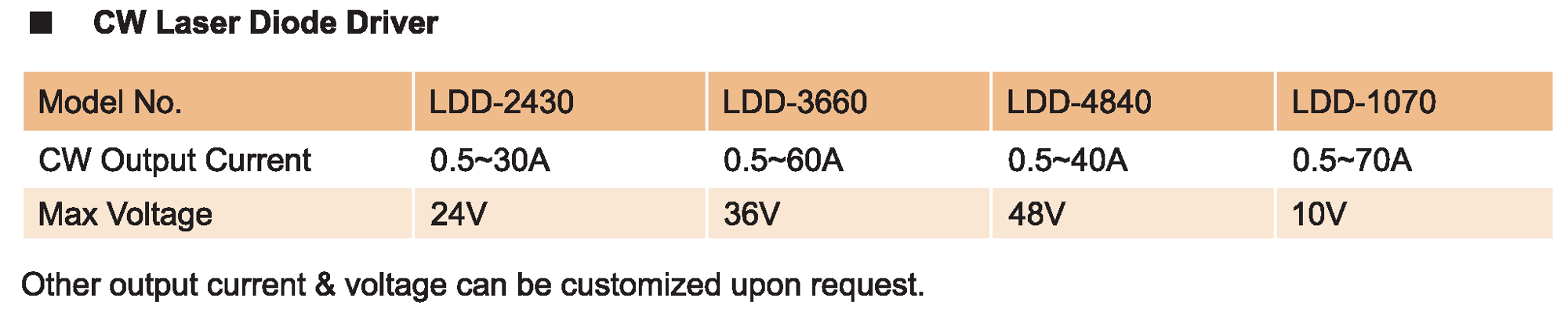

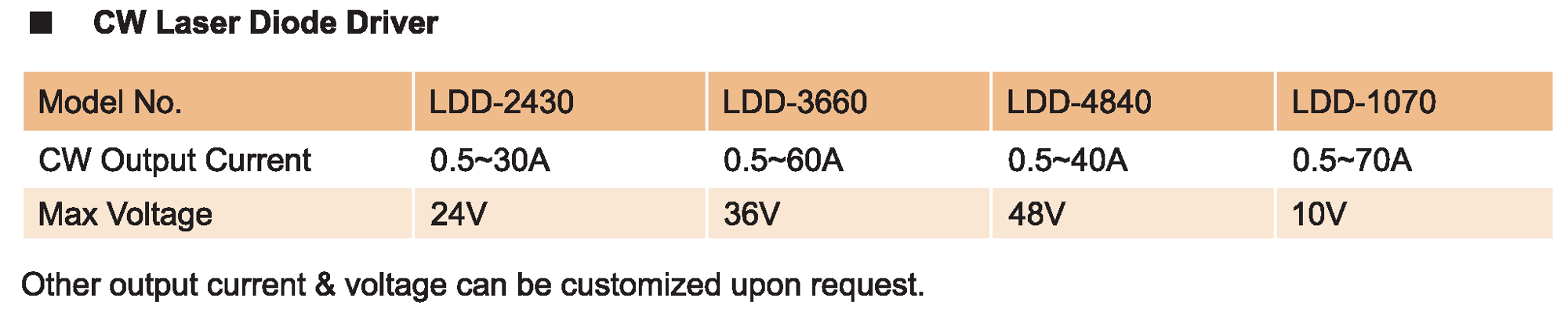

3) The laser module must be driven by professional laser diode driver. If you are using other supplier’s laser diode

driver, please contact us in advance to get permission.

4) Remove the covers at the ends of the Nd:YAG rod. Adjust the beam path and other optics.

5) Start the water chiller. Adjust the target temperature (20-25

℃

as normal) and check the pressure. Then make

sure the water flow is smooth and flow rate is enough.

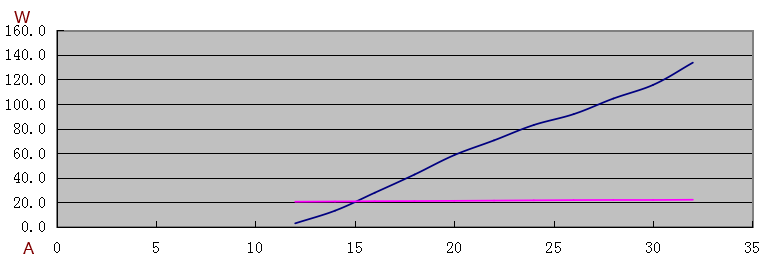

6) Start the laser diode driver, push the LD ON button and adjust the current set to drive the laser module. Increase

the current slowly till the recommended operation current. If the output power of 1064nm is too weak compared

with the datasheet, please adjust the HR & OC to optimize the output power. If necessary, you can adjust the

chiller’s temperature to improve the output power, too.

7) When the operation is over, please adjust the current slowly till minimum current, and then turn off the LD ON

button and shut down the diode driver. Then, shut down the chiller.

2. Maintenance

1)

Deionized water or purified water must be used for the chiller and water filter for the chiller is must. Check the

water monthly for the color and conductance for the water. If the color of the water changed, or the resistance

<0.5M/cm, the water and filter must be changed.

2)

If the DPSS laser module has ever been stored in low temperature, especially for < 0

℃

(there may be ice inside),

you should put the laser module in regular temperature environment for 12 hours to ensure the inside heat

balance has been achieved.

3)

Please don’t stay too long time after you start the chiller to avoid water condensing inside the module.

4)

The optical resonator & cavity must be sealed and the environment should be clean. Check both ends of the

Nd:YAG rod regularly to ensure there is no dust attached.

5)

If there is any emergency during operation, you can turn off the laser diode driver by the LD ON button directly

(instead of adjust the current set), and then shut down the chiller and any other power supply switches.

3.

Operation Notice

1) This component comes with high power 1064nm laser, and the security level is CLASS I. Protections must be

taken during the operation to avoid harm to human eyes and bodies. Any operator must be well trained before

operation and laser goggles are necessary.

2) The chiller cooling capability and pressure must be qualified.

3) Operation at higher current than the current limit is strictly prohibited or the laser module may be damaged.

4) The laser module must be horizontally placed and leaning & shaking is prohibited.

5) If the laser module is not used, please cover the laser rod ends to avoid dust.

6) Storage under 0

℃

is strictly prohibited or there may be ice inside the module. If it has been stored under 0

℃

,

please keep it at a warm environment for 12 hours before operation.

7) Environment with high temperature, high moisture and too much dust will influence the life time of the laser

module, and please avoid using the module in such situations.

4. Warranty Notice

Please take necessary protections for the operation of the laser diode module, and notice that following situations

can not be warranted:

1) Over current damage over current limit (please set the current limit as instructed).

2) Over heat damage (usually happens to the operation without chiller protection wire connected).

3) Condensation-water damage (air conditioner is recommended).

4) Open the laser modules or remove the service tags without permission.

5) Other manual operating mistakes.

Hot Searches