- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2020

-

Weight (KG):

-

3000 KG

-

Power (kW):

-

11.93

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

White

-

Certification:

-

ISO9001/CE

-

Type:

-

horizontal drilling machine

-

Voltage:

-

220v/380v/415v Optional

-

Model:

-

MZB73214

-

Place of Original:

-

Qingdao China

-

Usage:

-

drill holes

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xiking

-

Machine Type:

-

drilling machine

-

Marketing Type:

-

Hot Product 2020

-

Weight (KG):

-

3000 KG

-

Power (kW):

-

11.93

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

White

-

Certification:

-

ISO9001/CE

-

Type:

-

horizontal drilling machine

-

Voltage:

-

220v/380v/415v Optional

-

Model:

-

MZB73214

-

Place of Original:

-

Qingdao China

-

Usage:

-

drill holes

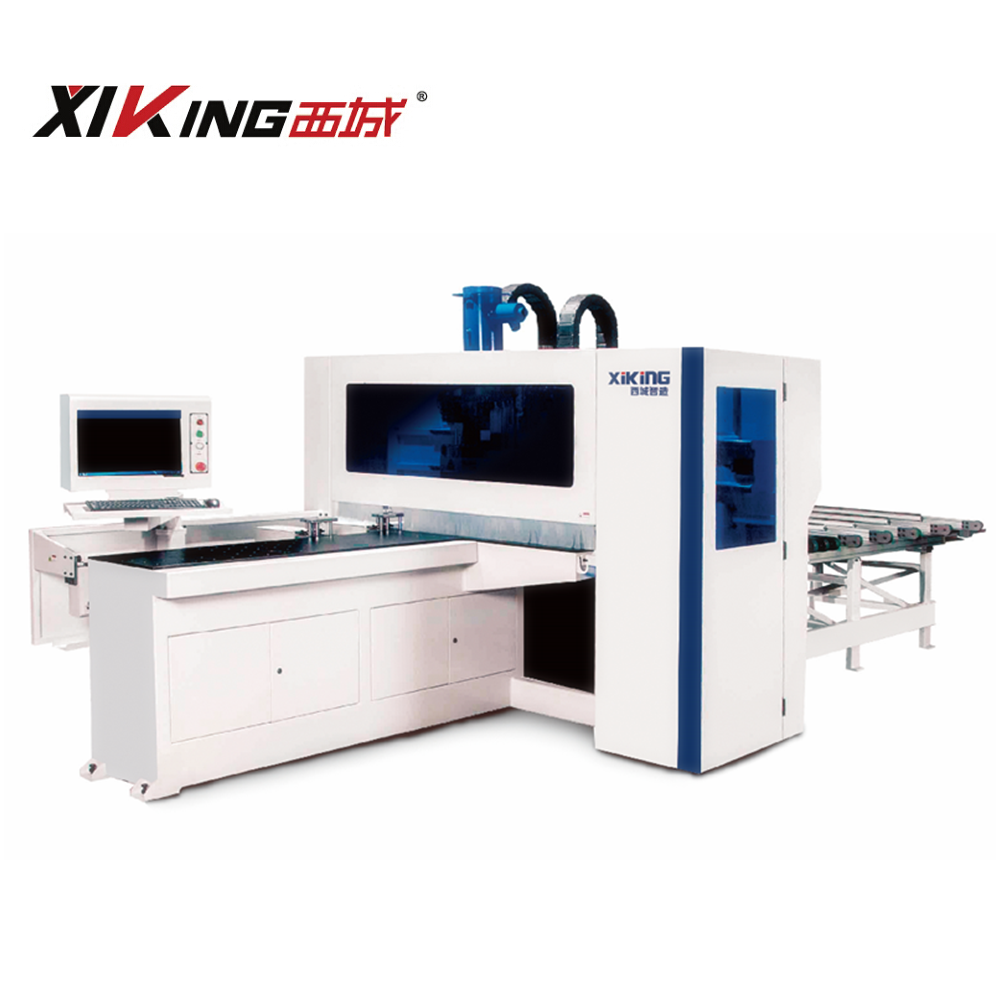

Product Overview

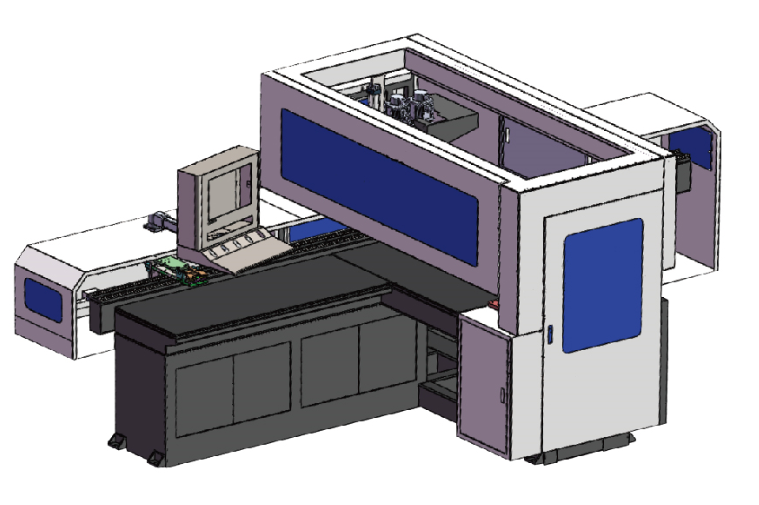

NC Boring Machine

Machine Details

Machine functions :

2. The front and back slots can be processed at the same time, so that it can improve process efficiency.

Can drill six sides at one time

Machine parameter

Can drill six sides at one time

Can groove and cutting at front and back panel

|

X axis travelling

|

4200mm

|

|

Y axis travelling

|

1800mm

|

|

Z axis travelling

|

250mm

|

|

Working panel length

|

150mm~3050mm

|

|

Working panel width

|

40mm~1250mm

|

|

Working panel thickness

|

10mm~60mm

|

|

X axis max moving speed

|

130m/min

|

|

Y axis max moving speed

|

75m/min

|

|

Z axis max moving speed

|

30m/min

|

|

up vertical driller

|

5+7

|

|

up horizontal driller

|

X2×2 Y2×2

|

|

Down vertical driller

|

7pcs

|

|

Driller motor

|

2.2KW×2

|

|

Milling speed

|

8000r/min

|

|

Milling spindle motor

|

3.5kw×2

|

|

Working table height

|

900mm

|

|

Dust collector diameter

|

125mm

|

|

Total power

|

19.8kw

|

|

voltage

|

380/220/415V 50/60HZ

|

|

air pressure

|

0.6-0.8Mpa

|

|

weight

|

3500Kg

|

|

size

|

4800mm×2750mm×2300mm

|

XIKING Machine Features

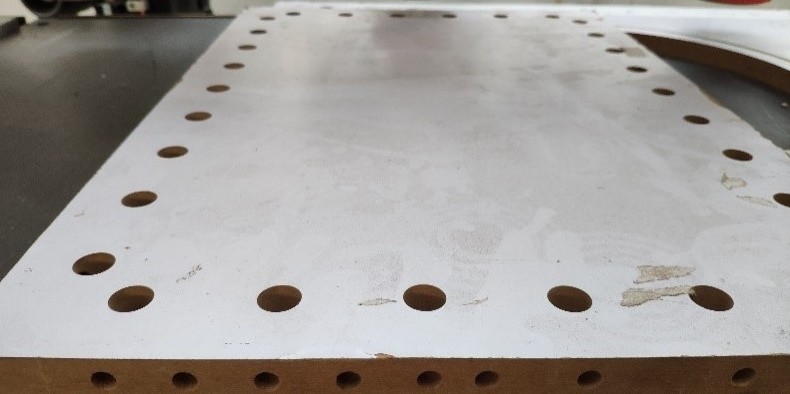

▓Completely pass-through punching, complete punching and slotting at one time;

▓The largest workpiece is 2440*1220mm;

▓Scan the barcode to automatically load the NC program for processing;

▓One person can operate the machine up to more than 1,000 pieces per day;

▓Seamlessly dock various production design software in the industry;

▓No need to turn over or turn around, no need for secondary processing;

▓Realize fast and efficient drilling work and greatly reduce labor costs;

▓Optional different wiring schemes for incoming and outgoing materials (forward in and forward out, forward in and backward out)

▓Optional discharging system, supporting automatic conveying roller or side discharging to realize automatic intelligent production and processing;

▓Independent servo control long guide rail double gripper, double gripper mechanism cooperates with multiple platen mechanisms;

▓Automatic repositioning of double grippers and automatic adjustment of the clamping position according to the length of the plate, which can easily process large and small plates without additional adjustment;

▓German control system, graphic input interface, quick and convenient operation;

▓Side leaning device and air-floating work surface ensure processing accuracy and prevent scratching of the plate;

▓It adopts a 6-kilowatt electric spindle, comes with a cylindrical universal ball pressing plate mechanism, and adopts a rack and

pinion transmission method for the side support;

▓Used with electronic saw or cutting machine, the front end only needs to be cut, and the back end is punched to assist slotting

▓The largest workpiece is 2440*1220mm;

▓Scan the barcode to automatically load the NC program for processing;

▓One person can operate the machine up to more than 1,000 pieces per day;

▓Seamlessly dock various production design software in the industry;

▓No need to turn over or turn around, no need for secondary processing;

▓Realize fast and efficient drilling work and greatly reduce labor costs;

▓Optional different wiring schemes for incoming and outgoing materials (forward in and forward out, forward in and backward out)

▓Optional discharging system, supporting automatic conveying roller or side discharging to realize automatic intelligent production and processing;

▓Independent servo control long guide rail double gripper, double gripper mechanism cooperates with multiple platen mechanisms;

▓Automatic repositioning of double grippers and automatic adjustment of the clamping position according to the length of the plate, which can easily process large and small plates without additional adjustment;

▓German control system, graphic input interface, quick and convenient operation;

▓Side leaning device and air-floating work surface ensure processing accuracy and prevent scratching of the plate;

▓It adopts a 6-kilowatt electric spindle, comes with a cylindrical universal ball pressing plate mechanism, and adopts a rack and

pinion transmission method for the side support;

▓Used with electronic saw or cutting machine, the front end only needs to be cut, and the back end is punched to assist slotting

Our Advantages

Drilling is more stable and precise

According to the size of the plate and the position of the hole, the pressing device is determined to meet the needs of the workpiece when drilling or feeding, and the force is uniform to achieve the best drilling effect.

slotting at one time.

ensure fine transmission.

accuracy.

The guide rail imported from Taiwan has excellent dust-proof performance, large contact surface and strong load-bearing capacity.

The mounting surface of the guide rail is milled on a large-scale milling machine, and CNC punched, with high installation accuracy

The mounting surface of the guide rail is milled on a large-scale milling machine, and CNC punched, with high installation accuracy

Trade Show

Hot Searches