- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BETA

-

Year:

-

2024

-

Voltage:

-

380V/50HZ or customized

-

Dimension(L*W*H):

-

4000*1500*2670

-

Hollow part volume:

-

300-1500ml

-

Clamping Force (kN):

-

2200

-

Power (kW):

-

55

-

Weight (KG):

-

3500 KG

-

Keywords:

-

Automatic Bottle Blowing Machine

-

Suitable bottle:

-

PET Bottle Size 0.3-1.5L

-

Blowing Type:

-

Stretch Blowing

-

Machine type:

-

PET Blowing

-

Bottle material:

-

PET

-

Bottle type:

-

Round Square Bottle

-

Function:

-

Auto Blow Molding

-

PLC:

-

MITISUBISHI

-

Product name:

-

High Speed Servo Motor Automatic PET Bottle Blow Moulding Machine

Quick Details

-

Neck Diameter(mm):

-

50 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BETA

-

Year:

-

2024

-

Voltage:

-

380V/50HZ or customized

-

Dimension(L*W*H):

-

4000*1500*2670

-

Hollow part volume:

-

300-1500ml

-

Clamping Force (kN):

-

2200

-

Power (kW):

-

55

-

Weight (KG):

-

3500 KG

-

Keywords:

-

Automatic Bottle Blowing Machine

-

Suitable bottle:

-

PET Bottle Size 0.3-1.5L

-

Blowing Type:

-

Stretch Blowing

-

Machine type:

-

PET Blowing

-

Bottle material:

-

PET

-

Bottle type:

-

Round Square Bottle

-

Function:

-

Auto Blow Molding

-

PLC:

-

MITISUBISHI

-

Product name:

-

High Speed Servo Motor Automatic PET Bottle Blow Moulding Machine

Product Description

Bottle Making Machine Fully Automatic High Speed Plastic PET Bottle Blwoing Machine

BETA high speed &energy saving series is a stable two-step blow-down stretch automatic blowing machine.It can be used from 4 cavity to 10 cavity,suitable for blowing any kind of carbonated beverage bottle,sparkling beverage bottle,pure water bottle, mineral water bottle,fruit juice beverage bottle,cosmetic bottles,large diameter bottles, high temperature resistance bottles and other packaging bottles.

Product Details

Efficient embryo supply system

The fully automatic preform sorting and loading mechanism not only achieves fast and efficient sorting and loading process to save labor costs but also further improves the entire equipment workflow stability.

Preform separation

Preform separation:When the preform signal is detected, the preform separation cylinder moves forward to insert preforms, the degermination cylinder rises to degerminate, and the preform separation cylinder moves to the left to separate preform.

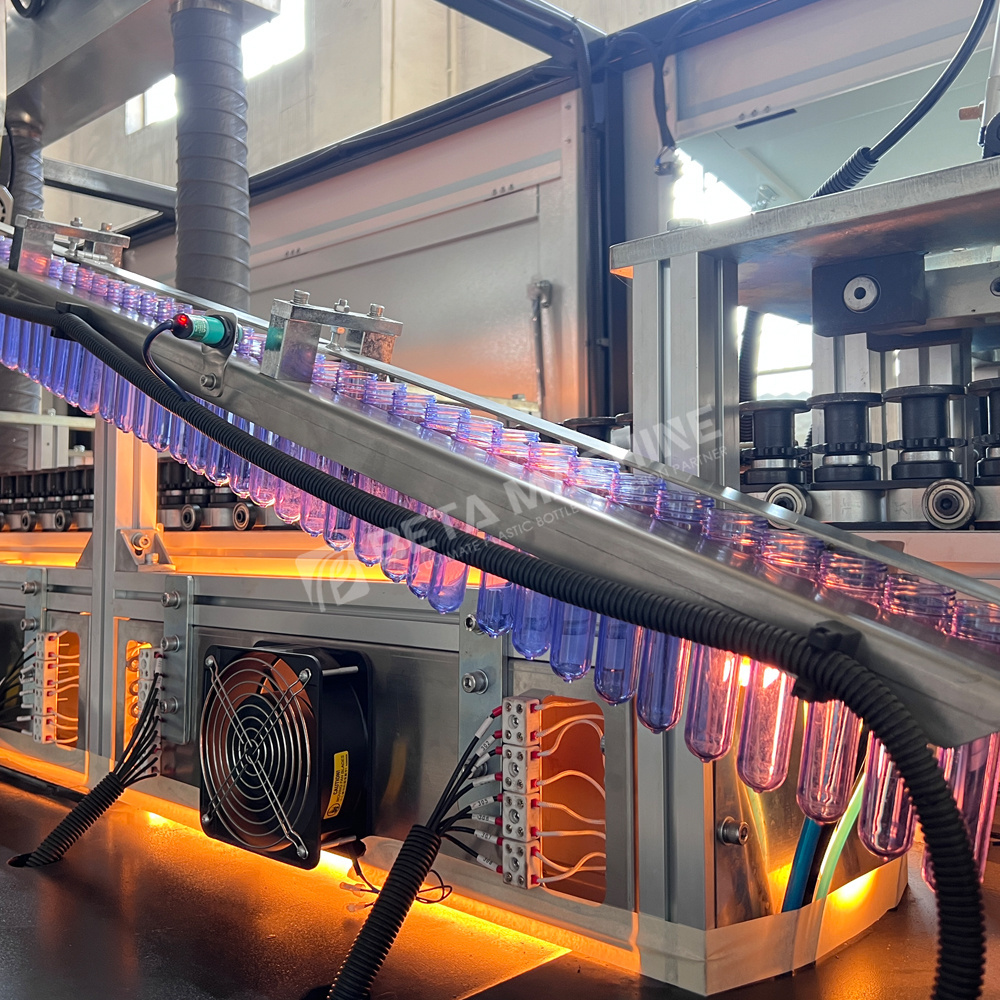

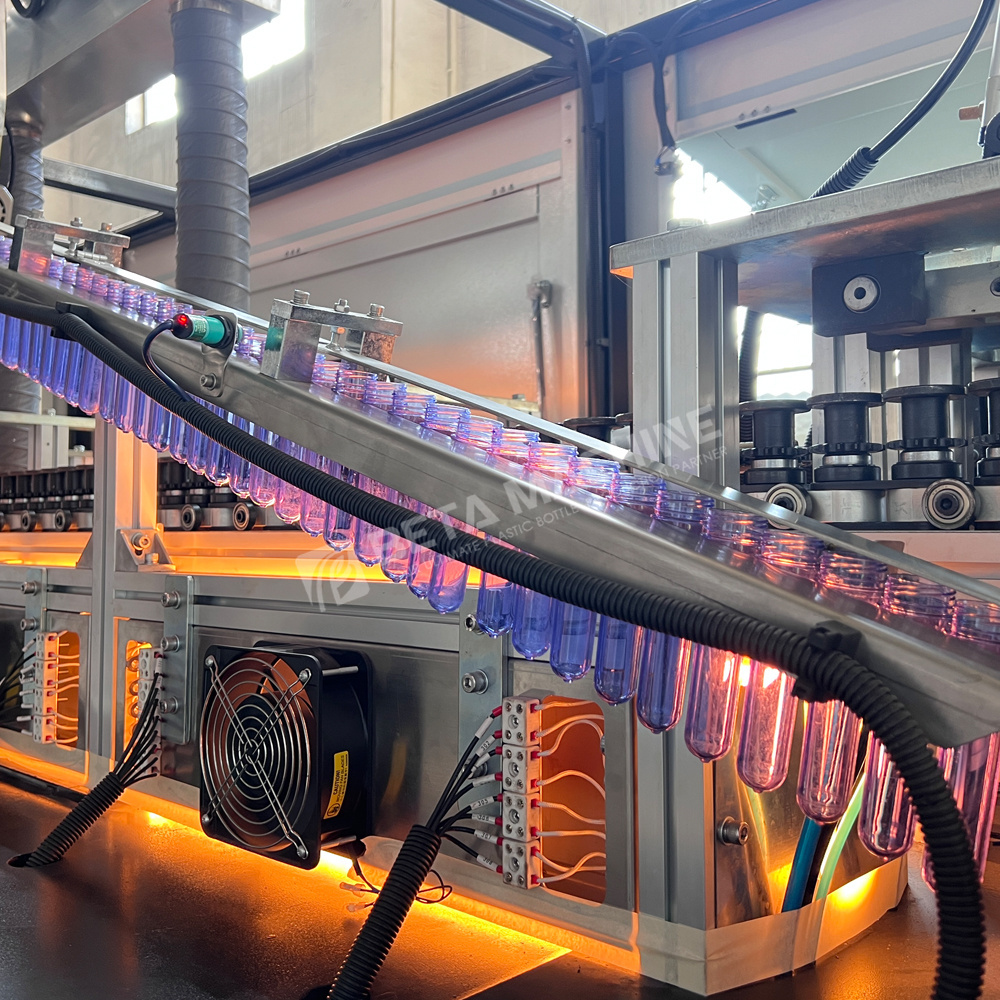

Intelligent heating system

The lamp is used to penetrate the preform for heating,making the preform stretch more evenly with high transparency.Equipped with a stainless steel mirror reflective plate to make full use of the heat energy of the lamp to shorten heating time, reduce energy consumption and increase production capacity.The temperature of each layer of lamp tubes can be adjusted independently, and the temperature can be adjusted up and down,front and back according to the customer's different preform.

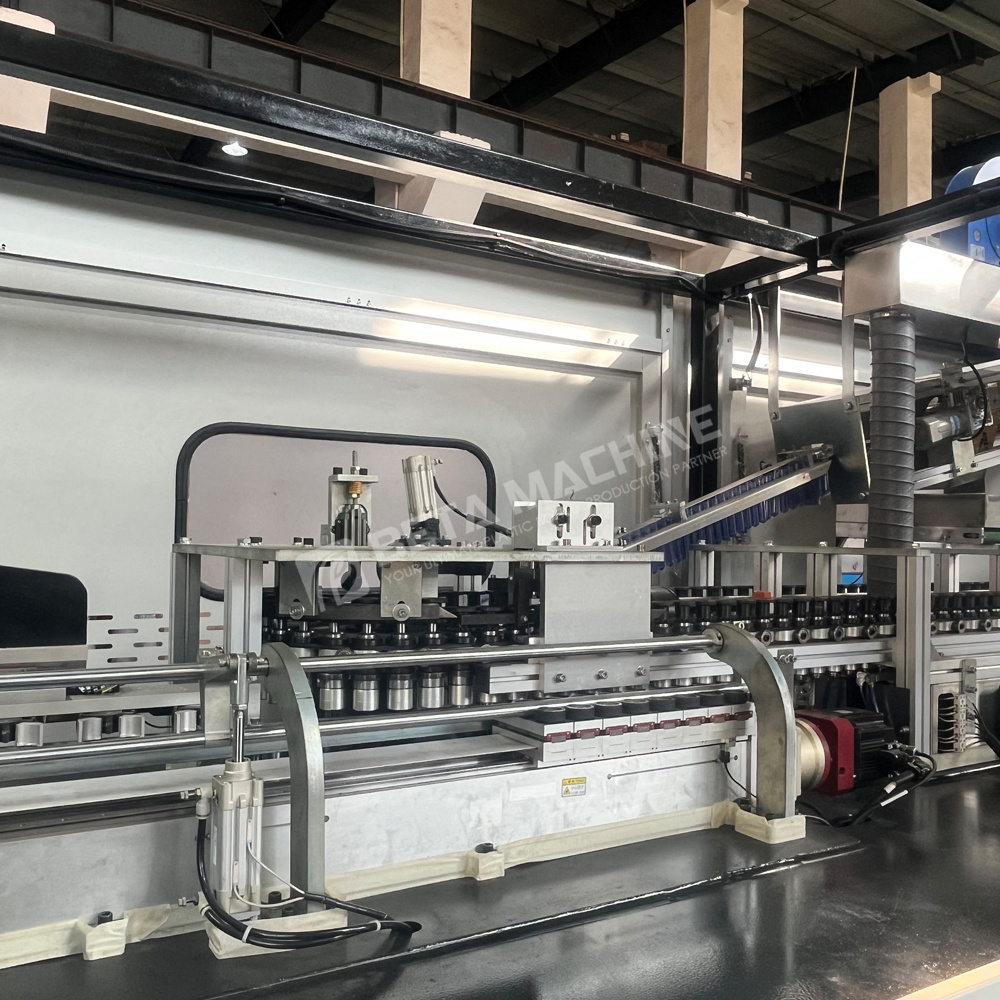

Servo mold clamping system

The mold clamping system is driven by a servo motor and mechanical connecting rod transmission.The mold and bottom mold are closed synchronously through servo motors.The back of the mold base is equipped with a high-pressure boosting plate and high-pressure mold locking, which effectively reduces the visibility of the mold closing line of finished bottles and ensures the quality of the bottles.The mold adopts a drawer-type structure, which makes it easy to replace the mold, and the operator can complete it within half an hour.

Servo stretching system

Servo motor drives stretching system.The servo motor drives the gear rack to pull stretch, the independently developed photoelectric limit and mechanical limit dual protection modes prevent the stretching rod from touching the bottom mold.The first and second blow cycle times can be adjusted individually on the console.According to different bottle preforms and different bottle types of customers, the stretching rod can be quickly adjusted.It adjusts automatically and has high flexibility.

Cooling/chilled water circulation system

Cooling and heating head device ensures cooling of the heating head after it comes out of the bottle.There is a cooling water channel under the heating box. When the preform is heated, the cooling water channel is used to block the heat of the lamp. There is a cold air system below the cooling water channel to cool the bottle mouth and protect the mouth from deformation. Chilled water flows to the mold to quickly cool the mold and improve the production efficiency of the whole machine.

Product Paramenters

|

Model No.

|

NBH-4

|

NBQH-6

|

NBQH-6D

|

NBQH-8

|

NBQH-8D

|

NBQH-10

|

|

Production Capacity(BPH)

|

4000-6000

|

9000-12000

|

8000-11000

|

12000-16000

|

10000-15000

|

16000-20000

|

|

Container volume(L)

|

0.3-1.5

|

0.3-0.6

|

0.3-1.5

|

0.3-0.6

|

0.3-1.5

|

0.3-0.6

|

|

Bottle height(mm)

|

120-330

|

45-65

|

120-330

|

120-230

|

120-330

|

120-230

|

|

Bottle diameter(mm)

|

45-105

|

50-130

|

45-105

|

45-65

|

45-105

|

45-65

|

|

Preform length(mm)

|

50-130

|

50-130

|

50-130

|

50-130

|

50-130

|

50-130

|

|

Host dimensions(m)

|

4*1.5*2.67

|

5.4*1.6*2.67

|

5.9*1.6*2.67

|

5.9*1.6*2.67

|

6.9*1.6*2.67

|

7.2*1.6*2.67

|

|

Bottle unscrambler dimensions(m)

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

|

High pressure air pressure(Mpa)

|

4

|

4

|

4

|

4

|

4

|

4

|

|

Working pressure(Mpa)

|

0.8

|

0.8

|

0.8

|

0.8

|

0.8

|

0.8

|

|

Voltage(V)

|

380

|

380

|

380

|

380

|

380

|

380

|

|

Installation power(kw)

|

55

|

90

|

95

|

127

|

127

|

159

|

|

Actual power(%)

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

|

Mold cooling(HP)

|

5

|

8

|

10

|

10

|

12

|

12

|

|

Applicable material

|

PET

|

PET

|

PET

|

PET

|

PET

|

PET

|

|

Weight(T)

|

3.5

|

5.5

|

6

|

6

|

6.5

|

7

|

Recommend Products

Extrusion Blow Molding

Injection Molding Machine

Injection Blow Molding

Cap Compression

Machine

Machine

Molding

Machine

Why Choose Us

BETA understand the importance of providing high-quality plastic bottles manufacturing solutions for a wide range of applications. Whether you are in the beverage industry, personal care sector, or need bottles for household items, we have the expertise and capabilities to meet your needs.

Our experienced team will work closely with you to fully understand your specific requirements. We will take into account your brand identity, product specifications, and any other considerations to design custom bottle solutions that align perfectly with your vision.

BETA committed to sustainability and eco-friendly practices. As part of our efforts, BETA is also function to incorporate recycled materials into our manufacturing process and optimize energy consumption. By choosing BETA plastic machinery, you can be confident that you are making a responsible choice for the environment.

"Experience efficiency and excellence with our comprehensive plastic bottle production services. We are your ultimate partner, providing end-to-end solutions for all your bottle manufacturing requirements. From initial concept development to the final production, our team of experts is dedicated to delivering high-quality bottles that meet your specifications.

Contact us today to discuss your plastic bottle making needs. We are excited to collaborate with you and bring your vision to life.

Certificates.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

Customers

We are a professional manufacturer of blowing machinery in China. With the scientific progressive conception of rapid introduction, we make our machinery cover all over the overseas market. We have been producing our goods with mature techniques and first-class quality.

FAQ

1.

Who are we?

We are based in Jiangsu, China, start from 2017,sell to Domestic Market(70.00%),Mid East(10.00%),Southeast Asia(10.00%),Eastern Europe(5.00%),Eastern Asia(5.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Stretch Bottle Blow Molding Machine,Extrusion Blow Molding Machine,Injection Molding Machine,Injection Blow Molding Machine,Cap Compression Molding Machine

4. Why should you buy from us not from other suppliers?

Experience efficiency and excellence with our comprehensive plastic bottle production services. We are your ultimate partner, providing end-to-end solutions for all your bottle manufacturing requirements.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,French

We are based in Jiangsu, China, start from 2017,sell to Domestic Market(70.00%),Mid East(10.00%),Southeast Asia(10.00%),Eastern Europe(5.00%),Eastern Asia(5.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Stretch Bottle Blow Molding Machine,Extrusion Blow Molding Machine,Injection Molding Machine,Injection Blow Molding Machine,Cap Compression Molding Machine

4. Why should you buy from us not from other suppliers?

Experience efficiency and excellence with our comprehensive plastic bottle production services. We are your ultimate partner, providing end-to-end solutions for all your bottle manufacturing requirements.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,French

Hot Searches