Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

34.7 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOGDA

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

4300x1600x2500mm for extruder

-

Power (kW):

-

75

-

Weight:

-

18000 KG

-

Product name:

-

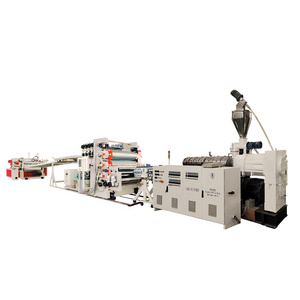

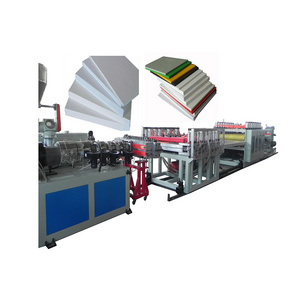

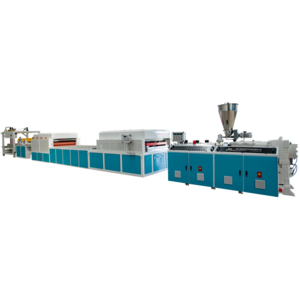

PVC foam board sheet manufacturing line

-

Raw material:

-

PVC Resins+CaCo3 + other material

-

Processing Type:

-

PVC Foaming Extrusion Line

-

Inverter:

-

ABB Brand

-

Motor:

-

Siemens Brand

-

Temperature control:

-

Omron Brand

-

Contactor:

-

Siemens Contactor/DELIXI

-

Application Field:

-

Producing plastic sheet

-

Screw type:

-

Twin Conical Screw

-

Gear box:

-

Jiangyin

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

Screw diameter (mm):

-

80/156

-

Screw Speed (rpm):

-

34.7 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOGDA

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

4300x1600x2500mm for extruder

-

Power (kW):

-

75

-

Weight:

-

18000 KG

-

Product name:

-

PVC foam board sheet manufacturing line

-

Raw material:

-

PVC Resins+CaCo3 + other material

-

Processing Type:

-

PVC Foaming Extrusion Line

-

Inverter:

-

ABB Brand

-

Motor:

-

Siemens Brand

-

Temperature control:

-

Omron Brand

-

Contactor:

-

Siemens Contactor/DELIXI

-

Application Field:

-

Producing plastic sheet

-

Screw type:

-

Twin Conical Screw

-

Gear box:

-

Jiangyin

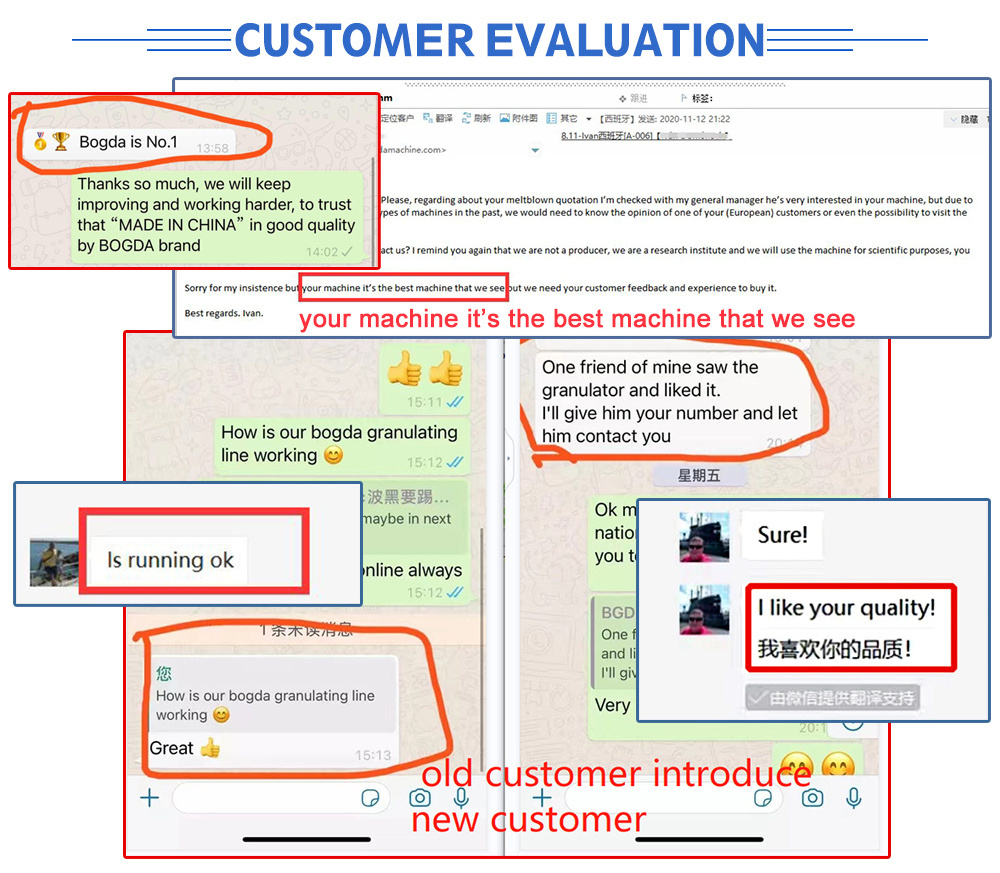

Why Choose BOGDA?

1. Bogda uses internationally renowned brand motors and appliances for customers to buy locally.

2. Bogda can do plant planning for customers and maximize benefits with minimal cost.

3. Bogda adopts special screw, long life, high plasticization.

4. Bogda machinery high degree of automation, low energy consumption, high output.

5. Bogda equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, Bogda will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

2. Bogda can do plant planning for customers and maximize benefits with minimal cost.

3. Bogda adopts special screw, long life, high plasticization.

4. Bogda machinery high degree of automation, low energy consumption, high output.

5. Bogda equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, Bogda will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

Production Application

Product Description

PET Film Laminated Glossy Effect PVC WPC Foam Board Solid Wall Panel Extrusion Production Line

The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with cooling fan.

|

PET Film Laminated Glossy Effect PVC WPC Foam Board Solid Wall Panel Extrusion Production Line

|

|

|

|

|

||||

|

Model

|

Product Width

|

Product Thickness

|

Capacity

|

Main Motor Power

|

||||

|

SJSZ80/156PL

|

1220mm

|

5-40mm

|

600kg/h

|

75KW

|

||||

Extrusion Mould T-die And SIEMENS PLC Touch Screen Control System

1. Die head with streamlined runner surface, two half mold body design, die head disassembly, easy to clean.

2. Manual fine tuning of elastic die lip or movable upper die lip design, extrusion thickness 0.2-1.22mm. Special for lace

products and can be adjusted according to the thickness of products.

3. To adapt to the melt flow of different viscosity to get uniform distribution.

4. Die body adopts die steel or imported alloy steel to prolong the life of the die.

5. All the surface of the runner is plated with hard chromium, the average thickness is 25μm~50μm, and mirror polished. 6. Die head fasteners with high strength bolts of class 12.9.

7. The heating element adopts durable stainless steel heating rod and heating ring

2. Manual fine tuning of elastic die lip or movable upper die lip design, extrusion thickness 0.2-1.22mm. Special for lace

products and can be adjusted according to the thickness of products.

3. To adapt to the melt flow of different viscosity to get uniform distribution.

4. Die body adopts die steel or imported alloy steel to prolong the life of the die.

5. All the surface of the runner is plated with hard chromium, the average thickness is 25μm~50μm, and mirror polished. 6. Die head fasteners with high strength bolts of class 12.9.

7. The heating element adopts durable stainless steel heating rod and heating ring

Calibration Forming Machine For PVC Foam Board

Number of set boards: four pairs. Width of shaping board: 1500mm Finalize plate closure: cylinder drive, independent up and down control Plate cooling: water cooling, optimize the design of flow channel Longitudinal movement of setting machine: 0.75 kW reducer motor drive

Cooling stacker with edge side cutting device

Length: 5 m Transition roller: stainless steel, surface polished, hardening treatment

Haul-off machine for pvc foam board

Rubber roller material: polyurethane adhesive Clamping mode: each pair of rollers is pressed by independent cylinder Drive: reducer motor Motor power: 5.5KW, 2 sets synchronous traction Control: Swiss ABB frequency converter

Non-dust Cutting Machine And SUS Stacker For PVC Foam Board

Effective cutting width: 1500mm Cutting method: dust-free blade

Best Selling

Packing & Delivery

Company Introduction

BOGDA Machinery Group

is located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

The main products of the company are:

1. PVC/PP/PE wood plastic production lines

2. PVC/PP/ wide sheet production lines

3. PVC/UPVC door and window profiles, ceiling panels, wall panels, window sill panels, wall hanging panels and other profiles extrusion production lines

4. PC/PA/ABS and other profiles production lines

5. PVC pipe production lines

6. HDPE/PE/PVC/PPR/PERT solid wall pipe production lines, as well as HDPE/PE gas pipe production lines

7. Vertical and horizontal HDPE/PP/PVC corrugated pipe production lines & reinforced winding pipe production lines

8. Multi-layer and single-layer PE/PP/PS/HIPS/GPPS/PC/ABS/PLA/PET/PMMA/GPPS/APET/PETG sheet production line

9. EVA/POE/PVB/SGP film production line; TPU/TVB film and lithium battery separator production line

10. All kinds of PE/PP/PLA/PET pelletizing units

11. PVC/PE/PP automated centralized feeding system

12. PP meltblown fabric and various spunbond non-woven fabric production lines

13. SPC LVT PVC Floor Production Line

14. PVC foamed board extrusion production lines

15. Recycling auxiliary equipment related to extrusion line, such as extrusion mold, plastic shredder, plastic crusher, plastic

pulverizer, cooling tower, automatic screw loader, hopper dryer, plastic mixer and etc.

BOGDA has advanced design concepts in the extrusion field, strives for perfection in product quality, and continues to improve in technology. It can provide customized solutions for each customer to meet the different needs of customers. Project planning, product positioning, plant planning, equipment installation and commissioning, customer staff training, equipment after-sales maintenance and other all-round services. Our advantage is to provide customers with desired, satisfactory, and high-quality products to help customers create the greatest Profits and business opportunities, customer success is our ultimate goal.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

The main products of the company are:

1. PVC/PP/PE wood plastic production lines

2. PVC/PP/ wide sheet production lines

3. PVC/UPVC door and window profiles, ceiling panels, wall panels, window sill panels, wall hanging panels and other profiles extrusion production lines

4. PC/PA/ABS and other profiles production lines

5. PVC pipe production lines

6. HDPE/PE/PVC/PPR/PERT solid wall pipe production lines, as well as HDPE/PE gas pipe production lines

7. Vertical and horizontal HDPE/PP/PVC corrugated pipe production lines & reinforced winding pipe production lines

8. Multi-layer and single-layer PE/PP/PS/HIPS/GPPS/PC/ABS/PLA/PET/PMMA/GPPS/APET/PETG sheet production line

9. EVA/POE/PVB/SGP film production line; TPU/TVB film and lithium battery separator production line

10. All kinds of PE/PP/PLA/PET pelletizing units

11. PVC/PE/PP automated centralized feeding system

12. PP meltblown fabric and various spunbond non-woven fabric production lines

13. SPC LVT PVC Floor Production Line

14. PVC foamed board extrusion production lines

15. Recycling auxiliary equipment related to extrusion line, such as extrusion mold, plastic shredder, plastic crusher, plastic

pulverizer, cooling tower, automatic screw loader, hopper dryer, plastic mixer and etc.

BOGDA has advanced design concepts in the extrusion field, strives for perfection in product quality, and continues to improve in technology. It can provide customized solutions for each customer to meet the different needs of customers. Project planning, product positioning, plant planning, equipment installation and commissioning, customer staff training, equipment after-sales maintenance and other all-round services. Our advantage is to provide customers with desired, satisfactory, and high-quality products to help customers create the greatest Profits and business opportunities, customer success is our ultimate goal.

FAQ

1. How many electric, water, air need for the machines?

BOGDA: technical department supply the whole layout for workshop details.

2. Can I operate machine if don’t have experienced engineers?

BOGDA: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

BOGDA: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

BOGDA: 12 months since the first day customer operates (except wear parts)

5. How can u help us when face some technical problem?

BOGDA: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

BOGDA: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

BOGDA: technical department supply the whole layout for workshop details.

2. Can I operate machine if don’t have experienced engineers?

BOGDA: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

BOGDA: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

BOGDA: 12 months since the first day customer operates (except wear parts)

5. How can u help us when face some technical problem?

BOGDA: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

BOGDA: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Hot Searches