- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.7kw

-

Dimension(L*W*H):

-

1760*1230*1440mm

-

Weight:

-

750 KG

-

Year:

-

2003

-

Working width:

-

420mm

-

Maximum thickness:

-

8mm

-

Minimum thickness:

-

0.6/0.2mm

-

Knife size:

-

0.7/50/3500

-

Feeding speed:

-

Motor flexible

-

Upper feeding:

-

Standard

-

Pressure:

-

Standard

-

Keywords:

-

Used camoga splitting machine

-

Application:

-

Leather goods, footwear, wallet, belt, ruber

Quick Details

-

Voltage:

-

380V/220V

-

Place of Origin:

-

Italy

-

Brand Name:

-

Camoga

-

Power:

-

2.7kw

-

Dimension(L*W*H):

-

1760*1230*1440mm

-

Weight:

-

750 KG

-

Year:

-

2003

-

Working width:

-

420mm

-

Maximum thickness:

-

8mm

-

Minimum thickness:

-

0.6/0.2mm

-

Knife size:

-

0.7/50/3500

-

Feeding speed:

-

Motor flexible

-

Upper feeding:

-

Standard

-

Pressure:

-

Standard

-

Keywords:

-

Used camoga splitting machine

-

Application:

-

Leather goods, footwear, wallet, belt, ruber

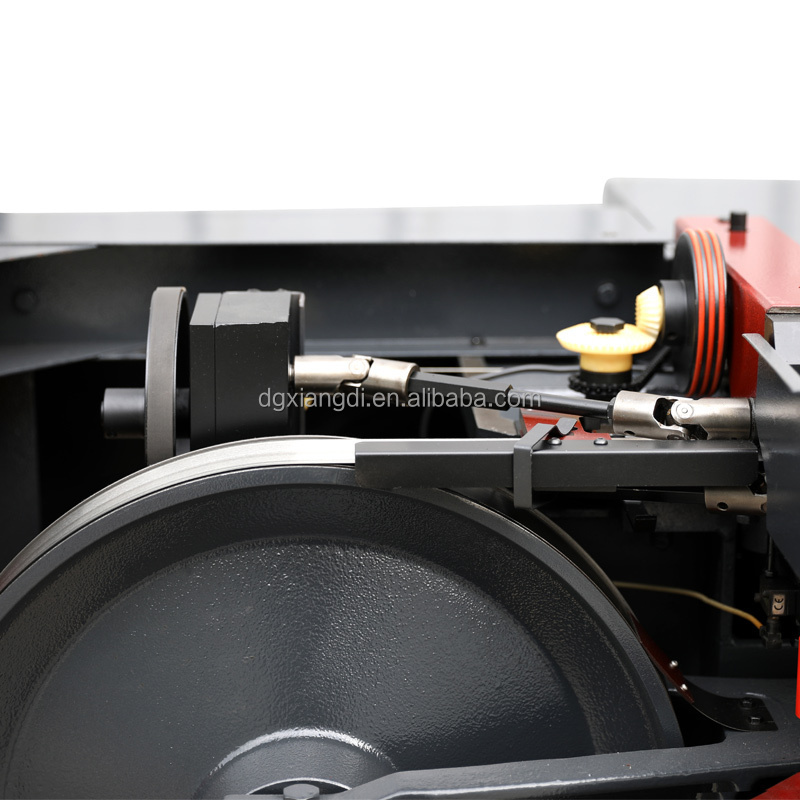

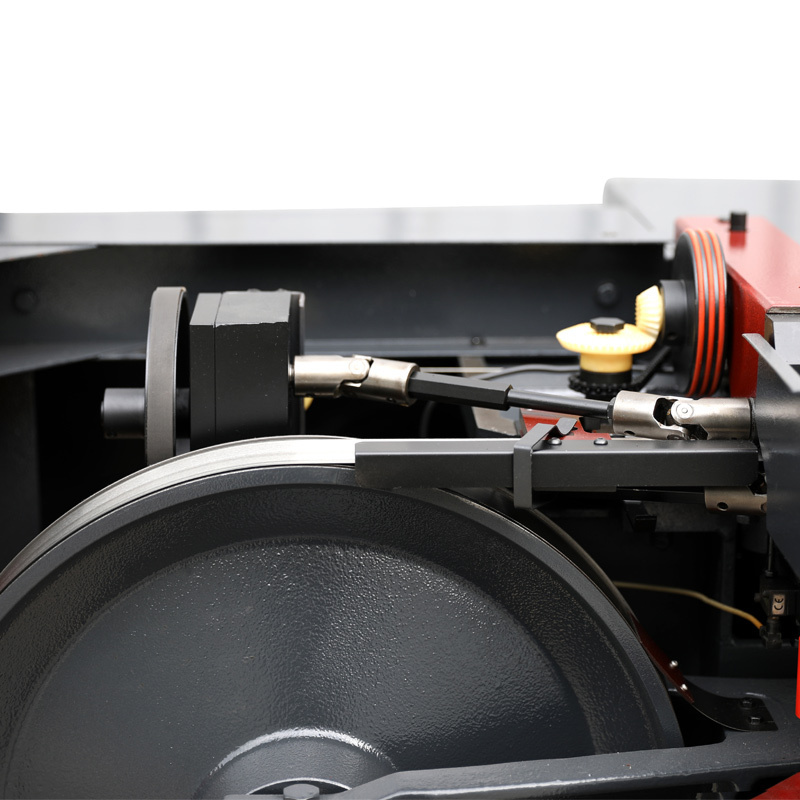

C420L Used Camoga Shoe Making Leather Splitting Machine

1.Used Camoga C420L band knife splitting machine.

2.Made in Italy.

3.Band knife trend requires no adjustment.

4.Knife grinding unit can use emery wheel or diamond wheel.

5.Simpleness:single knife grinding micro control device.

6.Activated rapid setting of blade width.

7.Independent cleaner of sharpening dust and waste.

8.The flywheel moves on the precise linear bearing track.

9.Rapid adjustment of work pressure.

10.Optical microscope examines the blade symmetry.

11.The digit shows the splitting width.

1 2.Detailed instructions and repair tools.

13.Rapidly change the feeding wheel and bar without dismantling the joint.

14.All fittings are easy to dismantle and convenient for rapid repairt and maintenance.

15.The mechanical parts are lubricate permanently.