- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZK

-

Dimension(L*W*H):

-

as capacity

-

Weight:

-

6000 KG, 92-485Ton

-

Certification:

-

CE&ISO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Spare parts supply:

-

For whole year

-

Test&installation:

-

Engineer assigned

-

After-sale service:

-

For whole using life

-

Grinding media:

-

steel ball

-

History:

-

65 years

-

Factory Visit:

-

Welcomed Warmly

Quick Details

-

Marketing Type:

-

New Product 2023

-

Capacity(t/h):

-

0.65-90TPH

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZK

-

Dimension(L*W*H):

-

as capacity

-

Weight:

-

6000 KG, 92-485Ton

-

Certification:

-

CE&ISO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Spare parts supply:

-

For whole year

-

Test&installation:

-

Engineer assigned

-

After-sale service:

-

For whole using life

-

Grinding media:

-

steel ball

-

History:

-

65 years

-

Factory Visit:

-

Welcomed Warmly

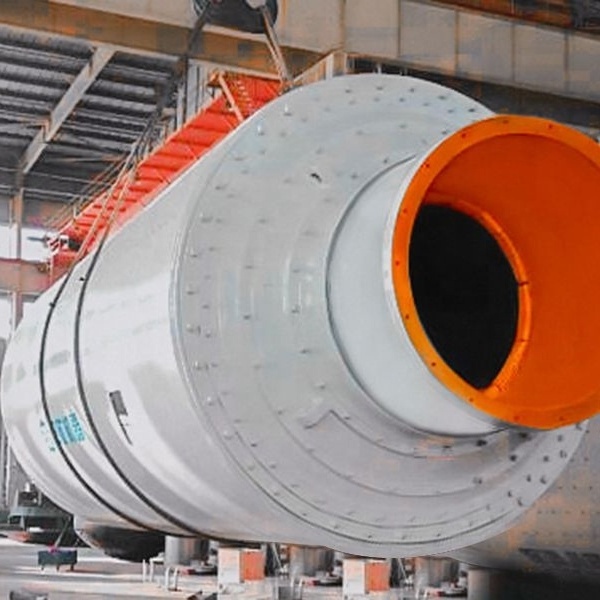

High Capacity Coal Grinding Ball Mill Coal Pulverizer Manufacturers

Brief introduction of Coal Powder Making Plant

Our Pulverized Coal Preparation Production Line is composed of Raw Coal Storage & Transportation System, Grinding System, Dust Collecting System, Electrical & Instrument Automation System. By the consideration of safety protection for equipment and system, explosion venting valve and nitrogen protection port are adopted at hot air inlet pipeline of Air Swept Coal Mill and coal air output pipeline. Speed of Powder Separator is regulated by VVF, the output fineness could be controlled by adjustment of frequency converter by remote control.

Application:

The coal powder grinding system is mainly used for burner of burning system in cement plant, lime plant etc, which can also applied in making coal powder which are used for the boilers in power plant and thermal power plant.

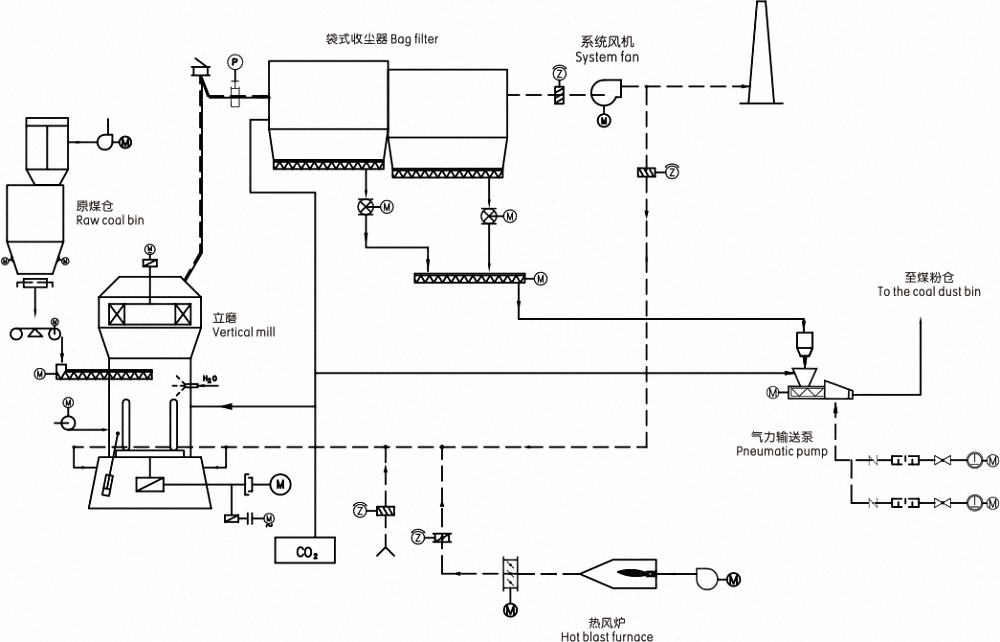

Production Process Flow Chart

The raw coal is stored in the raw coal bunker and fed into the vertical mill by the belt weigher in bottom of raw coal bunker. After drying, grinding and powder classifying, the coarse coal powder with unqualified size will be fall down onto the millstone again for grinding. Meanwhile the qualified coal powder will be discharged with airflow, and entered into the high concentration bag filter especially for coal mill, the air cleansing by bag fiter will be exhausted into the atmosphere., The coal powder collected by the dust collector will be conveyed into coal powder silo through the conveyor belt. Any sundries inside the raw coal, like coal gangue, metal block, etc, will be discharged out of the mill by vane. The coal powder prepareation system is designed with safety measures, like anti-explosion value, inert gas fire extinguishing system, etc.

| Specification | Load (t) | Cylinder speed (r/min) | Capacity (t/h) | motor model | Motor power (kW) | Voltage (V) | Weight (t) |

| φ1200x2400 | 4.8 | 32 | 1.4-2 | Y280M-8 | 45 | 380 | 11.2 |

| φ1500x3000 | 8 | 28.8 | 2-3 | JR125-8 | 95 | 380 | 19.7 |

| φ1700x2500 | 7.5 | 24.5 | 3-5 | JR116-6 | 95 | 380 | 24 |

| φ2200x3000 | 13 | 22 | 5-6 | JR136-8 | 180 | 380 | 33.5 |

| φ2200x4400 | 21 | 8-9 | YRKK4501-6 | 250 | 380 | 39 | |

| φ2200x5800 | 21 | 5.5-7 | Y4005-8 | 280 | 380 | 45.8 | |

| φ2400x4750 | 22 | 20 | 10-12 | YR400-8 | 280 | 6000 | 49 |

| φ2400x(4000+2000) | 10-11 | YRKK450-8 | 250 | 6000 | 56 | ||

| φ2400x(4500+2000) | 10-12 | YRKK500-8 | 280 | 6000 | 59.6 | ||

| φ2500x3900 | 14 | JR138-8 | 280 | 6000 | 53 | ||

| φ2600x(5250+2250) | 9-10 | YRKK500-8 | 400 | 6000 | 74.3 | ||

| φ2800x(5000+3000) | 13-13.5 | Y5001-8 | 500 | 6000 | |||

| φ2900 x4700 | 35 | 18.6 | 16 | JSQ1512-6 | 570 | 6000 | 81 |

Project Cases:

Pulverized Coal Preparation Station in Shangdong

Coal Powder Vertical Grinding Mill in Ningxia

If you are interested in it, please send us email with your specific needs