- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50Hz

-

Rated Power:

-

5kw

-

Dimension(L*W*H):

-

4000mmx10000mmx1800mm

-

Weight (KG):

-

1500 KG

-

Year:

-

2020

-

Effective cutting area:

-

3150mmx8000mm

-

Cutting mode:

-

Plasma Cutting+ Flame Cutting

-

Motor:

-

Panasonic Servo Motor

-

Control system:

-

F2300B

-

Height controller:

-

HYD

-

Plasma cutting speed:

-

3500mm/min

-

Flame cutting speed:

-

700mm/min

-

Input voltage:

-

380v/50Hz

-

Weight:

-

1500KG

-

File support:

-

DWG/DXF

Quick Details

-

Dimensions:

-

4000mmx10000mm

-

Place of Origin:

-

China

-

Model Number:

-

PFP-4010

-

Voltage:

-

380V/50Hz

-

Rated Power:

-

5kw

-

Dimension(L*W*H):

-

4000mmx10000mmx1800mm

-

Weight (KG):

-

1500 KG

-

Year:

-

2020

-

Effective cutting area:

-

3150mmx8000mm

-

Cutting mode:

-

Plasma Cutting+ Flame Cutting

-

Motor:

-

Panasonic Servo Motor

-

Control system:

-

F2300B

-

Height controller:

-

HYD

-

Plasma cutting speed:

-

3500mm/min

-

Flame cutting speed:

-

700mm/min

-

Input voltage:

-

380v/50Hz

-

Weight:

-

1500KG

-

File support:

-

DWG/DXF

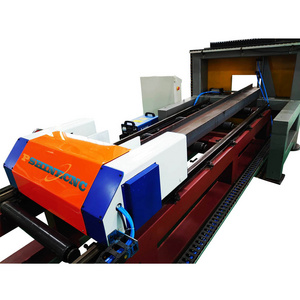

Water Tank China Affordable DIY CNC Plasma Cutter Table

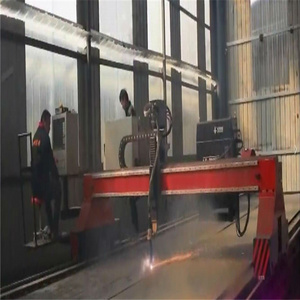

When using a plasma arc cutting, not only can cut carbon steel, but also cutting stainless steel, aluminum, copper and other metal materials, maximum cutting thickness determined by the plasma source with the decision. Normally, the device used by the U.S. sea treasure produced plasma power, plasma cutting speed relative to the oxyacetylene cutting speed, high efficiency, effectively reduce the overall cost.

When using oxyacetylene or other oxyfuel, only cutting carbon steel, cutting thickness 6 ~ 200mm, such as the use of special cutting torch, cutting nozzle and specialty gases, gas, maximum cutting thickness up to 300mm. Oxyfuel cutting, plasma cutting with respect to the slow, but a thick steel plate can be cut, and the use of low cost.

1. The machine body:

It is gantry type structure. The cross beams treated by whole annealing to eliminate stress so it has good rigidity and high strength without permanent deformation.

2. The vertical rails:

The vertical guide track adopts heavy rails. The surface has high precision after grinding . The rail length can be increased and decreased according to the requirements of users;Rails using 38Kg / m rail processed from the top surface and the side after grinding with high straightness and parallelism; foundation generally use concrete structure ( also available in steel ).

3. The cutting torch holder:

The cutting torch holder adopts the collision-preventing design to ensure the cutting torches are not damaged in production.

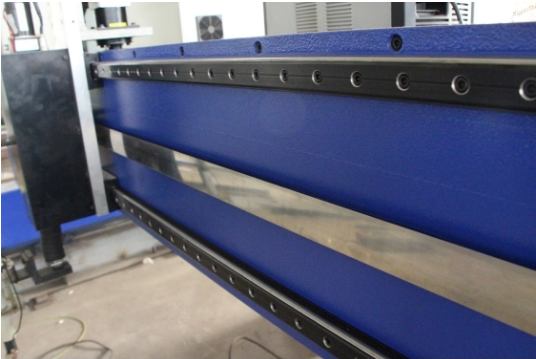

4. The horizontal rails:

The horizontal guide track adopts a straight line track with high precision and smooth running.

5. The travel reducer:

The travel reducer adopts high precision planet gear reducer.

6. The driven system:

The driven device adopts the full-digital AC servo system and motor made by Japan Panasonic which has high running precision.

7. Regulator of auto height regulator:

The machine has many functions such as automatic position, automatic perforation, and automatic height-regulating device of capacitance.

8. Program and nesting software:

FastCam.

9. CNC system:

It is equipped with most efficiency FL2300B Control system.

10. Cutting power:

China LGK or USA Hypertherm optional.

|

Rack structure

The cross beam adopts the German Messel technology and gantry frame, which can eliminate the torsion better. The crossbeam is a non-rectangular tube structure of the box steel structure. After welding, it is annealed entirely to eliminate the internal stress so that it will not deform in long-term use. The stable frame structure makes the cutting precision higher and the cutting speed faster.

|

|

Guide

The horizontal guideway adopts a domestic or imported double axle core linear guideway with high precision and good guidance.

Longitudinal guide rail with a grinding surface made of special metal has high mechanical accuracy and wear resistance

|

|

|

Servo drive system

Our servo drive system Panasonic, character position detection function, high accuracy, short acceleration time. The drive system adopts a Japanese original planetary reducer, whose input and output errors are only 16 arcs. Meanwhile, in the transverse and longitudinal gear transmission structure, an automatic clearance compensation device is added to enable the transmission structure to accurately execute the instructions issued by the NC system.

|

|

|

Cutting Torch Lifting Device

Cutting torch lifting rack is used to realize the automatic lifting of cutting torch.

|

|

|

Mechanical transmission device

All the mechanical transmission systems adopt the meshing of the precision gear and rack with the machining accuracy of Grade 7 of the national standard.

|

|

| EDGE® Connect, Hypertherm’s newest Computer Numeric Control (CNC) platform, delivers unmatched reliability, powerful embedded capabilities, and a high level of customizability. Based on our proprietary, industry-leading Phoenix® CNC platform , the system offers new, advanced software features – including ProNest® CNC automatic nesting delivering SureCut™ technology – along with enhanced hardware. | |

| ProNest ® CAD/CAM part nesting software for advanced mechanized cutting is designed to supercharge your cutting operation, helping you achieve greater automation, efficiency, and profitability. Brought to you by the cutting experts at Hypertherm, ProNest can optimize performance for plasma, laser, waterjet, and oxyfuel cutting machines. | |

|

Pressure gauge and relief valve

The pressure gauge and control valve is installed on the top of the central control panel so that the operator can adjust and check the gas pressure according to the optimum state during cutting. The panel has a switch for operating solenoid valve, which can be adjusted manually and controlled automatically by the numerical control system.

|

| Effective cutting length | 8000mm |

| Machine length | 10000mm |

| Effective cutting width | 3150mm |

| Machine width | 4000mm |

| Cutting mode | Plasma cutting+Flame cutting |

| Plasma cutting thickness | 1-30mm |

| Flame cutting thickness | 6-200mm |

| Plasma cutting speed | 3500mm/min |

| Flame cutting speed | 700mm/min |

| Input voltage | 380v,3 phaze,50Hz |

| Power | 5kw |

- --Pre-Sales Service

Free Pre-Sales Consulting / Free Sample Making

Speedy Laser offer 12 hours quick pre-sales response and free consulting. Any kind of technical support are available for users.

Free Sample Making is available.

Free Sample Testing is available.

We offer progressing solution design to all the distributor and users.

---After-sales Services

1. 3 year guarantee for main machine (People damaged are charged).

2. Full technical support\ by e-mail, call and video

3. Lifelong maintenance and spare parts supply.

4. Free design of fixtures as customers required.

5. Free training installation and operation for the staffs.

1.What kind of guarantee do you offer on your professional range of CNC and laser machine?

We offer a full 24 months back to base warranty on the router cnc and relevant manufacturers warranty on 3rd party add ons. This covers electrical and mechanical parts under ‘normal use’.

2.How do you send your CNC router and laser machine?

They are firstly greased thoroughly and packaged in a free-fumigation wooden crate. Usually, we send machine by ship, sometimes, as customer’s requirement, send by air or by train. When the goods arrive at your sea port or destination, you can pick up goods with the bill of lading we offered. Or we can arrange the cargo agent to send goods to your door.

3.I want a size that you don’t make as standard, is this possible?

Absolutely, we design and manufacture everything ourselves and indeed do many custom builds.

4.I am new to CNC and laser, how difficult are your machines to operate?

We help a lot of beginners, if you have a reasonable knowledge of computer and are willing to spend a little time learning it is not that had. Quite often when we sell a machine we send the manual out before the machine is ready for the customer to read ahead.

5.Does machine comes with software?

Yes, we offer intelligent and compatible software with machine, so it will be more convenient for you to operate machine.

6. Do you offer training about products?

Yes, customer could get free training at our factory; or we can assign technician arrive at customer’s company for the training at some charge, and accommodation, food, tickets will be charged.