- Product Details

- {{item.text}}

Quick Details

-

Arc Current:

-

29.6

-

Pulse Frequency:

-

50/60 HZ

-

Pilot Arc Current:

-

30A

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

490x230x385mm(LxWxH)

-

Use:

-

Welding

-

Voltage:

-

220V

-

Power:

-

500W

-

Weight (KG):

-

200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control:

-

automatic

-

Function:

-

Arc DC Welding Machine

-

Accessories:

-

Earth Clamp

-

Packing:

-

Wooden Case

-

Product name:

-

Inverter MMA Welding Machine

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

QUESTT

-

Marketing Type:

-

New Product 2022

-

Arc Current:

-

29.6

-

Pulse Frequency:

-

50/60 HZ

-

Pilot Arc Current:

-

30A

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

490x230x385mm(LxWxH)

-

Use:

-

Welding

-

Voltage:

-

220V

-

Power:

-

500W

-

Weight (KG):

-

200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control:

-

automatic

-

Function:

-

Arc DC Welding Machine

-

Accessories:

-

Earth Clamp

-

Packing:

-

Wooden Case

-

Product name:

-

Inverter MMA Welding Machine

-

Certification:

-

ISO

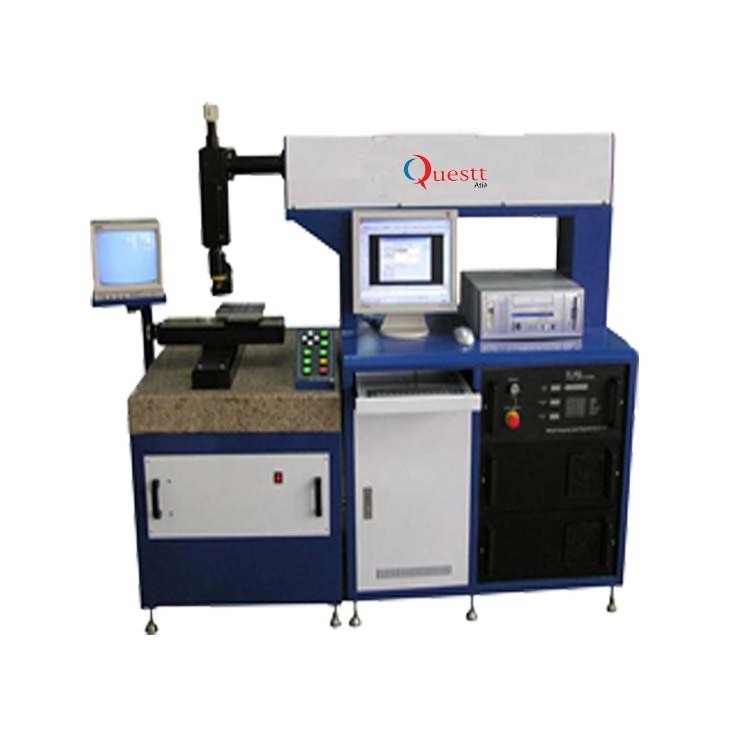

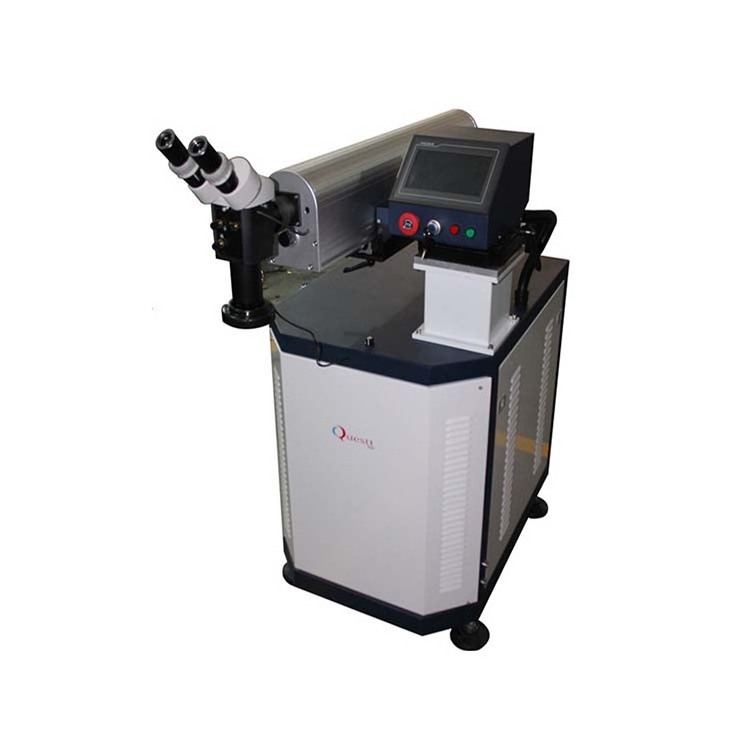

Product Introduction

This machine adopts the pulse laser of 1064nm wavelength generated by the laser generator. The laser is eradiated on the surface of the work pieces after being expanded, reflected and focused. The surface heat is diffused inside through heat transmission. The work piece is then melted through precisely controlling the parameters of the pulse laser like width, energy, peak power and repetition frequency, etc and the special melting pools will be formed. Thus the work pieces will be welded together. The laser welding of this machine is fast and the efficiency is high. The welding depth is large, the distortion is small and the ratio between the depth and the width is big. This machine can weld the materials that are difficult to be melted and can perform precise welding of micro miniature parts. Its exclusive laser technology can realize incomparable performances. The energy distribution of its welding spot is even and the machine has the best laser spot required by the characteristics of welding.

System components

The laser condensation cavity, the core part of this machine, adopts imported ceramic reflecting condensation cavity body. This machine is equipped with the 6KW single pulse/double pulse Xenon lamp, switching power supply, PLC control or computer numerical control system, X/Y axis electrical level-movement workbench/ rotating workbench(optional), CCD monitoring system(optional) and laser special cooling machine.

Application Fields and Applicable Materials

The welding machine is suitable for welding of gold, silver, platinum, stainless steel, titanium, etc and their alloy materials. The machine has been widely used in the aviation industry, spaceflight industry, weapon industry, ship industry, petrochemical industry, industry for home electrical appliance and household commodities, medical treatment industry, instrument industry, electronics and automobile industry, etc.

Specification

Model Number: LW200 /LW300 /LW400

|

|||||||||||||||||||||||||