- Product Details

- {{item.text}}

Quick Details

-

Rated Voltage:

-

600V

-

Tensile Strength:

-

10.3MPa min.

-

Color:

-

Black

-

Shrink ratio:

-

2:1

-

Usage:

-

Diesel-resistant

-

Working temperature:

-

-75℃~150℃

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KEHONG

-

Model Number:

-

DR-150

-

Rated Voltage:

-

600V

-

Tensile Strength:

-

10.3MPa min.

-

Color:

-

Black

-

Shrink ratio:

-

2:1

-

Usage:

-

Diesel-resistant

-

Working temperature:

-

-75℃~150℃

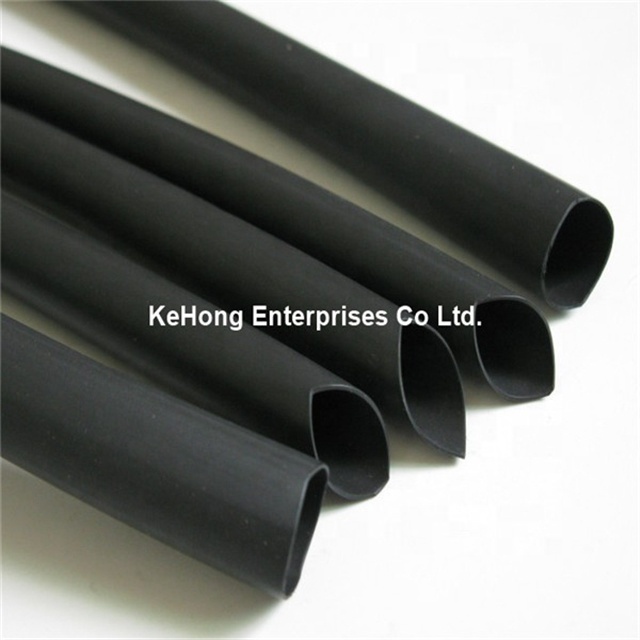

Diesel-resistant heat shrink tube AMS-DTL-23053/16

DR-150

Diesel-resistant, flexible, flame-retardant elastomer tubing

1) Application

Re sistance to aviation , diesel fuels, hydraulic fluids, and lubricating oils, DR -150 is ideal for applications require resistance to fuels, fluids and solvents. It is particularly suitable for protecting and bundling of high-performance cables and wiring harnesses.

2) Features/Benefits

Shrink ratio: 2:1

Outstanding fluid and heat resistance.

Abrasion resistance , excellent mechanical properties.

Flexible, and self extinguish

Conform to European RoHS environmental directive.

3) Operating Temperature Range

Operating temperature range: -75 ℃ ~150 ℃

Minimum full recovery temperature: 175 ℃

4) Specifications/Standards

AMS-DTL-23053/16

5) Specification values

| Property | Requirement | Test method | Typical value | |

| Physical: | Tensile strength | 11.7MPa min. | ASTM D 638 | ≥14MPa |

| Elongation | 250% min. | ASTM D 638 | ≥350% | |

| Heat shock 250℃, 4hrs | No cracking, dripping or flowing | ASTM D 2671 | Pass | |

| Low temperature flexibility -75℃, 4hrs | No cracking | ASTM D 2671 | Pass | |

| Aging 150℃, 168hrs | ||||

| Tensile strength after aging | 10.3MPa min. | ASTM D 638 | ≥12MPa | |

| Elongation after aging | 200% min. | ASTM D 638 | ≥300% | |

| Electrical: | Dielectric voltage withstand | 2500V,60sec,no breakdown | ASTM D 2671 | Pass |

| Dielectric strength | 11.9KV/mm min. | ASTM D 2671 | ≥11.9KV/mm | |

| Volume resistivity | 109Ω·cm min. | ASTM D 876 | ≥109Ω·.cm | |

| Chemical: | Corrosion | No corrosion | ASTM D 2671 | Pass |

| Flammability | Self extinguishing within 1 minute | ASTM D 2671 | Pass | |

| Fluid resistance: | 23℃,24hrs (aviation and diesel fuels, hydraulic fluids, lubricating oils, etc.) | |||

| Tensile strength | 10.4MPa min. | ASTM D 2671 | ≥12MPa | |

| Elongation | 200% min. | ASTM D 2671 | ≥300% | |

| Dielectric strength | 7.9KV/mm min. | ASTM D 2671 | ≥9.0KV/mm | |

6) Product sizes ( mm/inch )

| Size | Inside diameter | Wall thickness | Standard length | |

| As supplied(min.) | After recovery(max.) | After recovery | (m/spool) | |

| 1/8 | 3.2(0.125) | 1.6(0.062) | 0.76±0.15(0.030±0.006) | 100 |

| 3/16 | 4.8(0.187) | 2.4(0.093) | 0.84±0.15(0.033±0.006) | 100 |

| 1/4 | 6.4(0.250) | 3.2(0.125) | 0.89±0.15(0.035±0.006) | 100 |

| 3/8 | 9.5(0.375) | 4.8(0.187) | 1.02±0.20(0.040±0.008) | 50 |

| 1/2 | 12.7(0.500) | 6.4(0.250) | 1.22±0.20(0.048±0.008) | 30 |

| 3/4 | 19.1(0.750) | 9.5(0.375) | 1.45±0.28(0.057±0.011) | 30 |

| 1 | 25.4(1.000) | 12.7(0.500) | 1.78±0.28(0.070±0.011) | 30 |

| 1 1/2 | 38.1(1.500) | 19.0(0.750) | 2.41±0.41(0.095±0.016) | 15 |

| 2 | 50.8(2.000) | 25.4(1.000) | 2.79±0.41(0.110±0.016) | 22 |

1) What’s the delivery time of free heat shrink sample?

Within 1 day

2) Which payment terms and method do you accept?

TT in advance, or 30% TT in advance, 70% balance by copy of B/L

Pay to: our company account / on line of alibaba / Western Union / Paypal, etc

3) How these heat shrink tube will be freight please?

For one to two cartons of goods, freight by the agent of DHL,UPS,TNT,Fedex.

For LCL goods will be freight by sea or air.

Usually we can find the most competitive freight cost for our clients.

4) How to Warrant your heat shrink tubing quality?

Step1. Clarify the size, color, material, packing, and all other detail requirement before production;

Step 2. Strictly inspection made during production and before goods delivery from our factory.

Step 3. After goods received by client, once client feedback any technical mistake within 2 months, and proved this mistake/problem made by our production, we’ll provide qualified goods for free.

Hot products