Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

120

-

Weight:

-

2000 KG

-

Raw material:

-

HDPE / LDPE / PP / PE

-

Motor:

-

AC Motor

-

Usage:

-

ventilation system

-

Inverter:

-

ABB or Delta

-

Temperature controller:

-

Schneider Brand

-

Certification:

-

CE,ISO

-

Processing Type:

-

Exturding Machine

-

Products:

-

double wall corrugated pipe

-

After-sale service:

-

Engineer

-

Test machine video:

-

Provided

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

120

-

Weight:

-

2000 KG

-

Raw material:

-

HDPE / LDPE / PP / PE

-

Motor:

-

AC Motor

-

Usage:

-

ventilation system

-

Inverter:

-

ABB or Delta

-

Temperature controller:

-

Schneider Brand

-

Certification:

-

CE,ISO

-

Processing Type:

-

Exturding Machine

-

Products:

-

double wall corrugated pipe

-

After-sale service:

-

Engineer

-

Test machine video:

-

Provided

Product Overview

Double

wall corrugated pipe production line

FULLWIN Double wall corrugated pipe making machine is the hot sale product of our company. The whole production line consiste of two sets single screw extruders,die head and mould, forming machine,cutter and winder machine. It takes PE/PP grains as raw material. Finished pipes diameter raging from 40 mm to 110 mm and produced pipe have nice corrugated shape, consistent seam and both smooth inside and outside surface. This production line speed is about 2-4m/min (it depends on the specific pipe diameters).

FULLWIN Double wall corrugated pipe making machine is the hot sale product of our company. The whole production line consiste of two sets single screw extruders,die head and mould, forming machine,cutter and winder machine. It takes PE/PP grains as raw material. Finished pipes diameter raging from 40 mm to 110 mm and produced pipe have nice corrugated shape, consistent seam and both smooth inside and outside surface. This production line speed is about 2-4m/min (it depends on the specific pipe diameters).

|

NO.

|

Description

|

Quantity

|

|

1

|

Vacuum feeder and hopper dryer

|

2 Sets

|

|

2

|

SJ75/30 plastic single screw extruder

|

1 Set

|

|

3

|

SJ65/30 plastic single screw extruder

|

1 Set

|

|

4

|

Die head and mould

|

1 Set

|

|

5

|

Forming machine

|

1 Set

|

|

6

|

Cutting Machine with Counter Meter

|

1 Set

|

|

7

|

Plastic pipe winding machine

|

1 Set

|

Final product&Application

Brief introduction of production line

plastic single screw extruders

Fullwin independently developed single screw extruder is of high melt efficiency and continuous production stability. What is more, extraordinary performance gearbox reducer has long life and low noise. Fullwin single screw extruder can be used for PVC PE PP, three material production because its surface nitriding treatment which prolongs the screw using life. All these innovative design are for our clients' better using experience.

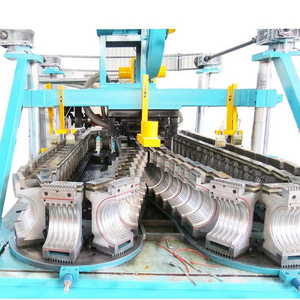

Forming machine

Water-cooling vacuum forming machine make the corrugated pipe produced more smooth and beautiful. We provide 52 pairs of block

molding modules that has nitriding and polishing treatment, making them durable. If purchase now, each different size set mould

provides 2 pairs of spare moulds.

molding modules that has nitriding and polishing treatment, making them durable. If purchase now, each different size set mould

provides 2 pairs of spare moulds.

Forming mould

Die head & mould mould & core bar

1. Fullwin special 6 grooves double screw die head is endowed with small resistance, large compression, stable discharge rate, fast heat conduction and water cooling system.

2. The cooling system loop on the inner side of the pipe wall at the mouth mold adopts professional heat insulation device for thermal insulation, which ensures the inner wall runner temperature can be constant and even, improving the stability of inner wall molding, making the inner wall more smooth.

3. Most importantly, Fullwin one size one die head design make our customers don't have to adjust the inner wall thickness. For the old design, different sizes pipe shared one die head must adjust inner wall thickness, this make the operation complicated and hard.

2. The cooling system loop on the inner side of the pipe wall at the mouth mold adopts professional heat insulation device for thermal insulation, which ensures the inner wall runner temperature can be constant and even, improving the stability of inner wall molding, making the inner wall more smooth.

3. Most importantly, Fullwin one size one die head design make our customers don't have to adjust the inner wall thickness. For the old design, different sizes pipe shared one die head must adjust inner wall thickness, this make the operation complicated and hard.

Cutting Machine with Counter Meter

Winder machine

Our team

Our factory is located in the beautiful Qingdao city, focus on plastic extrusion manufacturers. Our company has gathered first-class scientific research talents from all over the country. At present, has successfully developed a number of plastic machinery production lines and supporting equipment, including

single-wall corrugated pipe production line

,

double-wall corrugated pipe production line

, P

VC/ PP water supply pipe production line

,

profile and sheet production line

, etc. Among them, the corrugated production line has obtained a number of invention patents.

10000 m²

Workshop

Display A Lot Of Production Or Production Completed Machines

FULLWIN Customers Vist And Exhibitions

Shipping

After sales service

-After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply,

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer’s factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer’s factory.

- If buyer doesn’t request installation and commissioning by Seller’s engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer’s factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer’s factory.

- If buyer doesn’t request installation and commissioning by Seller’s engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

FAQ

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

Single Wall Corrugated Pipe Machine,Double Wall Corrugated Pipe Machine,PVC/ PP Water Supply Pipe Machine,WPC/PVC Profile and Sheet Profile Machine,PVC Fiber Reinforced Pipe Machine

3. why should you buy from us not from other suppliers?

1.Advanced production technology with design capability. 2.Reasonable price with good quality and best delivey time 3.Our sales team will give prompt feedback within 24 hours . 4.Profession after sales service system

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

Single Wall Corrugated Pipe Machine,Double Wall Corrugated Pipe Machine,PVC/ PP Water Supply Pipe Machine,WPC/PVC Profile and Sheet Profile Machine,PVC Fiber Reinforced Pipe Machine

3. why should you buy from us not from other suppliers?

1.Advanced production technology with design capability. 2.Reasonable price with good quality and best delivey time 3.Our sales team will give prompt feedback within 24 hours . 4.Profession after sales service system

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

Contact us

Recommend Products

Hot Searches