- Product Details

- {{item.text}}

Quick Details

-

Power:

-

60kw or 90 kw, 60kw or 90kw

-

Dimension(L*W*H):

-

1.45*0.5*1.1m, 1.45*0.5*1.1m

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

deformed steel bar making machine

-

Model:

-

CD-150

-

Making speed:

-

20-45m / min

-

Rolling size:

-

6-12mm

-

Color:

-

customized

-

Certification:

-

CE

-

Application:

-

Steel Industry

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengyuan

-

Voltage:

-

380V or customized

-

Power:

-

60kw or 90 kw, 60kw or 90kw

-

Dimension(L*W*H):

-

1.45*0.5*1.1m, 1.45*0.5*1.1m

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

deformed steel bar making machine

-

Model:

-

CD-150

-

Making speed:

-

20-45m / min

-

Rolling size:

-

6-12mm

-

Color:

-

customized

-

Certification:

-

CE

-

Application:

-

Steel Industry

deformed steel bar making machine

deformed steel bar making machine have two types,including two ribs cold rolling mill and three ribs cold rolling mill. Cold rolling mill is wire rod rolling into a threaded rod or wire.And the final bar will with 2 ribbed or 3 ribs.It can reduce costs and save about 40% steel.Tensile strength and yield strength of steel bar is reinforced. The raw material could be Q215,Q235,low carbon and middle carbon steel,etc.

Operating rules and maintain of deformed steel bar making machine

1. Before operating the machine, we should check the electric equipments, three phase electricity is ok, the machine bottom and so on

2. Check the lubrication whether is enough, the lubrication for the bearing

3. The raw materials distance should be at least 6-10mm from the derusting machine.

4.We should let the stress is suitable for the stress-relieving machine, If the stress is too big, the steel is easy to break

5. We should adjust the screw for strand line of wire diameter

6. When stop the machine, we need to stop the wire drawing machine firstly, then stop the steel plate machine

Advantages of deformed steel bar making machine

1.Easy to operate and high degree of automatic

2.High output and long service time

3. Through solid midfrequency heating, tensile strength of rebar can reach standard 400Mpa, 500Mpa and 600Mpa.

4. Roller adopts special alloy material and has four die cavities which can roll four different specifications of rebar, has advantage of easy adjustment, long service life, reducing the roller change trouble.

5.Easy to maintain and stable performance

Producing rib bar process of deformed steel bar making machine

Flow chart is:Wire rod → Materials shaft → Scaling and strength relieving machine → Rolling mill → Straighten machine → Fly shear → Rebar → Materials shaft → Final package

Main machine of deformed steel bar making machine

| Name | Unit | Power | Weight |

|

Feeding Materials shaft |

1 | / | 200kg |

|

Scaling and strength relieving machine |

1 | 2.2kw | 1300kg |

| Rolling mill | 1 | 160kw | 9500kg |

| Straighten machine | 1 | 15kw | 1800kg |

| Fly shear | 1 | 15kw | 1500kg |

|

Automatic materials shaft |

1 | 2.2kw | 300kg |

|

Jointing machine and electric control box |

1 | 3kw | 210kg |

Feeding materials shaft

Funcition:ready for raw material

Scaling and strength relieving machine

Function: the two machine is for reducing the rust on the wire rod, make wire rod more smoothly, the relieving machine will let wire rod more strength, anti-pulling.

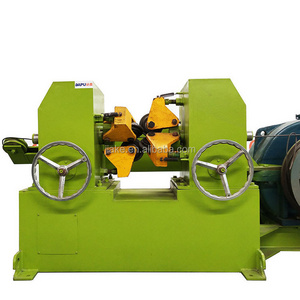

Rolling mill

Function: make two ribbed bar from wire rod.

Making speed: 3m/s

Mainly including the following parts

Alloy rollers, gear box reducer, frequency motor

Rollers is high-quality hard alloys, has advantage of smooth transmission, wear-resistant and durable.

The life of rollers could process 3000ton steel, then maintain, and reuse it again

Straighten machine

Function: After rolling, the rebar will go through the straig h ten machine,

Make the wire rod into rebar

It is consisted some wheels inside

There are 25pcs rollers in total

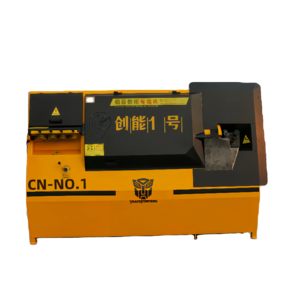

Fly shear

Fuction: it is for cutting rebar after making rebar

Cutting speed:3m/s

Cutting error:3mm

Cutting scope: 8 -1 6 mm

Capacity:20-100ton/h

Power: 15 kw

Including the sensor

Automatic materials shaft

Function: it is mainly for collecting rebar.

Automatic collecting way, save labor

Improve working eff i ciency

Jointing machine and electric control box

Joint i ng machine is mainly for joining the two wire rod end together

Electric box for controlling whole system

Main spare parts of deformed steel bar making machine

Our clients

Q:Do you have any other type of cold rolling machine?

A:Yes,we have.such as the smaller one,two ribs steel wire cold rolling mill LZJ-228,285.

Besides, we also have 3 ribs cold rolling mill.

Q:Do your machine could make rebar as we need to produce rebar size 3/8" and 1/2" that in metric 9.525mm and 12.5mm?

A:Yes, we could.

Q:Do your machine make hardness steel do up to as we need to produce up to USA standard grade 40 and grade 60?

A:Yes.Our machine is suitable for processing the low carbon, middle carbon steel and so on.