- Product Details

- {{item.text}}

Quick Details

-

mix ratio:

-

100:3

-

color:

-

white

-

hardness:

-

shore a 25

-

viscosity:

-

20000-25000 Mpa.s

-

working time:

-

30 minutes

-

curing time:

-

24 hours

-

tin cure silicone:

-

molding silicone

-

two part silicone:

-

condensation cure silicone

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

sanpin

-

Model Number:

-

SR-1025

-

mix ratio:

-

100:3

-

color:

-

white

-

hardness:

-

shore a 25

-

viscosity:

-

20000-25000 Mpa.s

-

working time:

-

30 minutes

-

curing time:

-

24 hours

-

tin cure silicone:

-

molding silicone

-

two part silicone:

-

condensation cure silicone

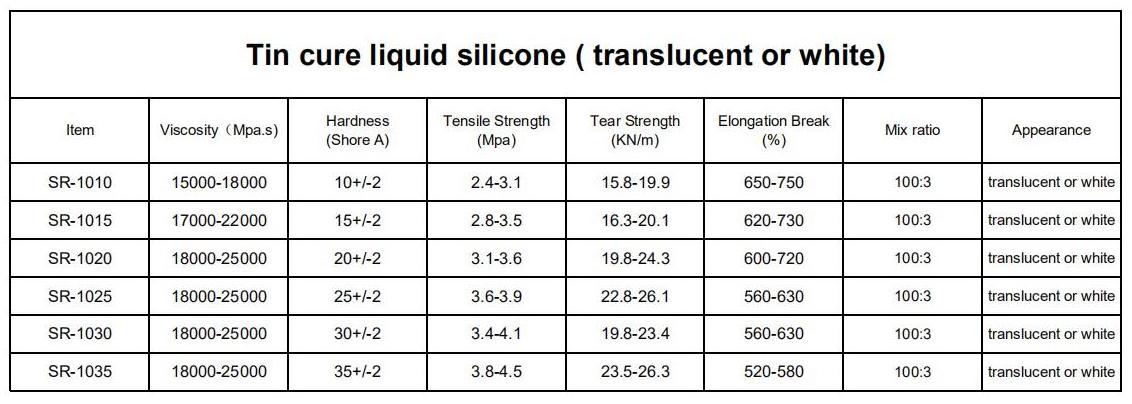

Tin cure liquid silicone is also called condensation cure liquid silicone, molding silicone. rtv 2 silicone. It is the materials of liquid shape. can be used in making rubber molds to copy any solid subjects. Here are some properties of the rtv silicone.

1. Easy to use by mixing the rtv silicone part A and part B only

2. Good flexibility.

3. Can copy the very fine detail of the surface

4. Strong tear strength and tensil strength

5. long shelf time like 12 months and more

6. adjustable working time and curing time.

7. Good liquidity and good flow ability.

How to use the rtv 2 silicone:

1. clean the surface of the prototype.

2. spray some release agent on the surface of the prototype.

3. put it into a frame with bottom ( like a container) and fix it.

4. mix the liquid silicone part A and Part B with certain mixing ratio completely, usually 100:3.

5. if you have vacuum chamber, put the mixed liquid silicone into the chamber and degas for 2 minutes.

6. pour the rtv silicone on the subject in the container fully.

7. after 24 hours. remove the rubber molds from the prototype.

8. rubber mold is done. start using the rubber mold.