- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Brand Name:

-

CNBM

-

Specification:

-

0.75mm coating on either side

-

Thickness:

-

6-50

-

Edge:

-

straight

-

Material:

-

Cement

-

Function:

-

Insulation

-

Product type:

-

Extruded Polystyrene (xps) Board Insulation

-

Item name:

-

Insulation Board

-

Color:

-

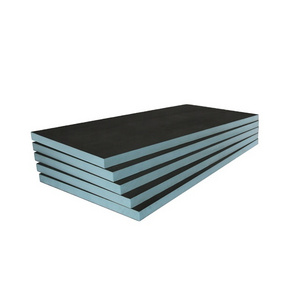

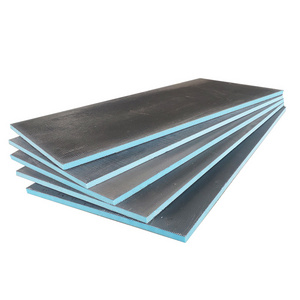

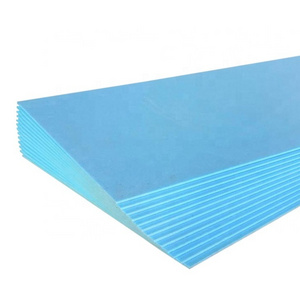

the surface is grey and the core material is light blue

-

Product name:

-

XPS Tile Backer Board

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Other

-

Project Solution Capability:

-

NONE

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Brand Name:

-

CNBM

-

Specification:

-

0.75mm coating on either side

-

Thickness:

-

6-50

-

Edge:

-

straight

-

Material:

-

Cement

-

Function:

-

Insulation

-

Product type:

-

Extruded Polystyrene (xps) Board Insulation

-

Item name:

-

Insulation Board

-

Color:

-

the surface is grey and the core material is light blue

-

Product name:

-

XPS Tile Backer Board

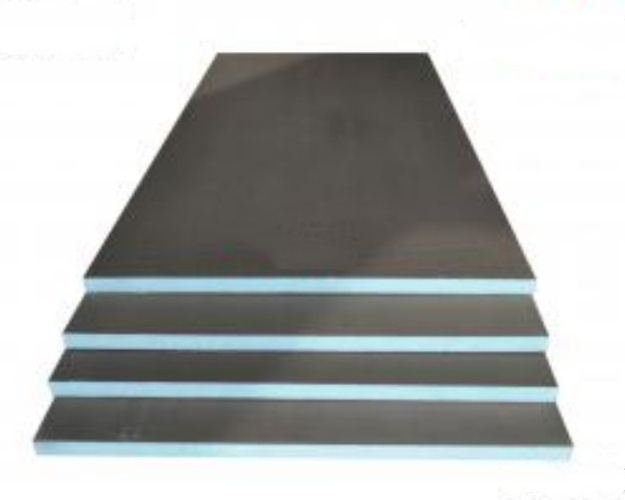

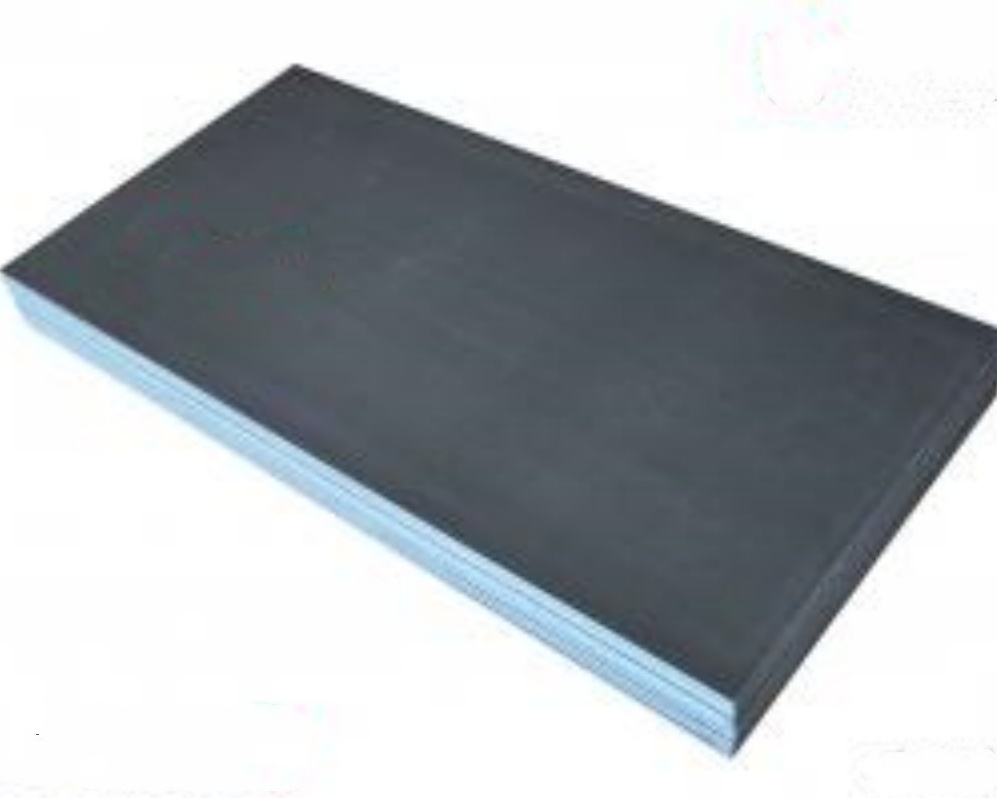

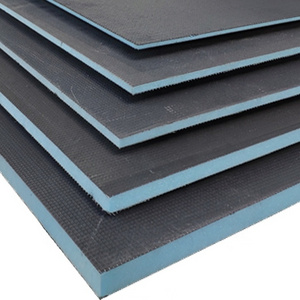

Product structure of Extruded Polystyrene XPS Tile Backer Board:

CMAX boards are made of high-performance waterproof extruded polystyrene (XPS Board), it has a 0.75mm coating on either side comprising a glassfiber mesh embedded in a polymer cement mortar.

O utstanding characteristics of Extruded Polystyrene XPS Tile Backer Board:

Both insulation and waterproof.

Product appearance of Extruded Polystyrene XPS Tile Backer Board:

The boards have straight edges. The color of the surface is grey and the core material is light blue.

Working temperature range:

50 to +80 °C

Standard dimensions and weight:

|

Thickness(mm) |

Weight(kg/m²) |

Length by width(mm*mm) |

|

6 |

2,7 |

1200 x 600 |

|

10 |

2,9 |

1250 x 600 |

|

12 |

3,0 |

2500 x 600 |

|

20 |

3.1 |

2500 x 600 |

|

30 |

3,3 |

2500 x 600 |

|

50 |

4,2 |

2500 x 600 |

The board has the following tolerances:thickness:± 2mm width:± 2mm length:± 3mm.

Reaction to FireExtruded Polystyrene XPS Tile Backer Board:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

Effect on indoor environment Extruded Polystyrene XPS Tile Backer Board:

CMAX board has been assessed as not emitting any particles, gases or radiation that may have a negative effect on the indoor climate or to have any significant effect on health.

Environmental declaration Extruded Polystyrene XPS Tile Backer Board:

The product does not contain any substances on the observation list of dangerous substances published by the national environmental authorities.

Main applications Extruded Polystyrene XPS Tile Backer Board:

Used as a watertight layer on walls and floors in houses, hotels and other wet areas such as bathroom, shower room.

Other applications Extruded Polystyrene XPS Tile Backer Board:

Other places to be insulated and waterproofed.

Applications Extruded Polystyrene XPS Tile Backer Board:

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

Waterproof strengthen:

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels Extruded Polystyrene XPS Tile Backer Board:

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.