- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Depending on machine capacity

-

Dimension(L*W*H):

-

Depending on machine capacity

-

Weight:

-

10000 KG

-

Production Capacity:

-

95%

-

Product name:

-

High Temperature Airflow Dyeing Machine

-

Local Service Location1:

-

Egypt

-

Local Service Location2:

-

Indonesia

-

Local Service Location3:

-

Colombia

-

Local Service Location4:

-

Bangladesh

-

Local Service Location5:

-

Uzbekistan

-

After-sales Service Provided1:

-

Video technical support

-

After-sales Service Provided2:

-

Online support

-

After-sales Service Provided3:

-

Field installation, commissioning and training

-

After-sales Service Provided4:

-

Field maintenance and repair service

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

China

-

Brand Name:

-

DONPRO

-

Power:

-

Depending on machine capacity

-

Dimension(L*W*H):

-

Depending on machine capacity

-

Weight:

-

10000 KG

-

Production Capacity:

-

95%

-

Product name:

-

High Temperature Airflow Dyeing Machine

-

Local Service Location1:

-

Egypt

-

Local Service Location2:

-

Indonesia

-

Local Service Location3:

-

Colombia

-

Local Service Location4:

-

Bangladesh

-

Local Service Location5:

-

Uzbekistan

-

After-sales Service Provided1:

-

Video technical support

-

After-sales Service Provided2:

-

Online support

-

After-sales Service Provided3:

-

Field installation, commissioning and training

-

After-sales Service Provided4:

-

Field maintenance and repair service

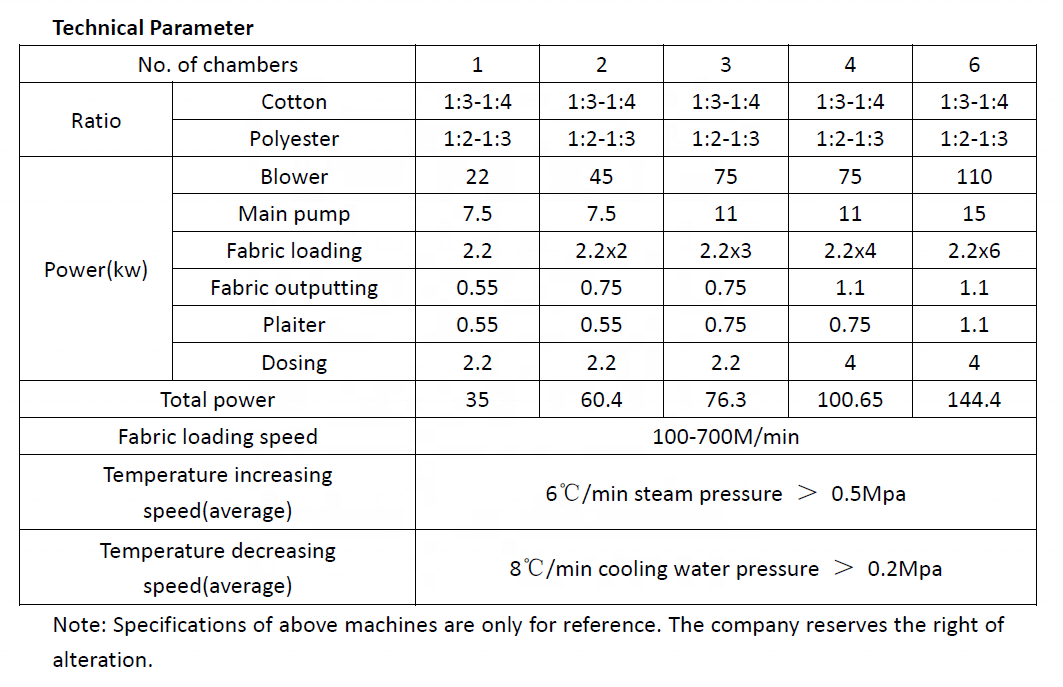

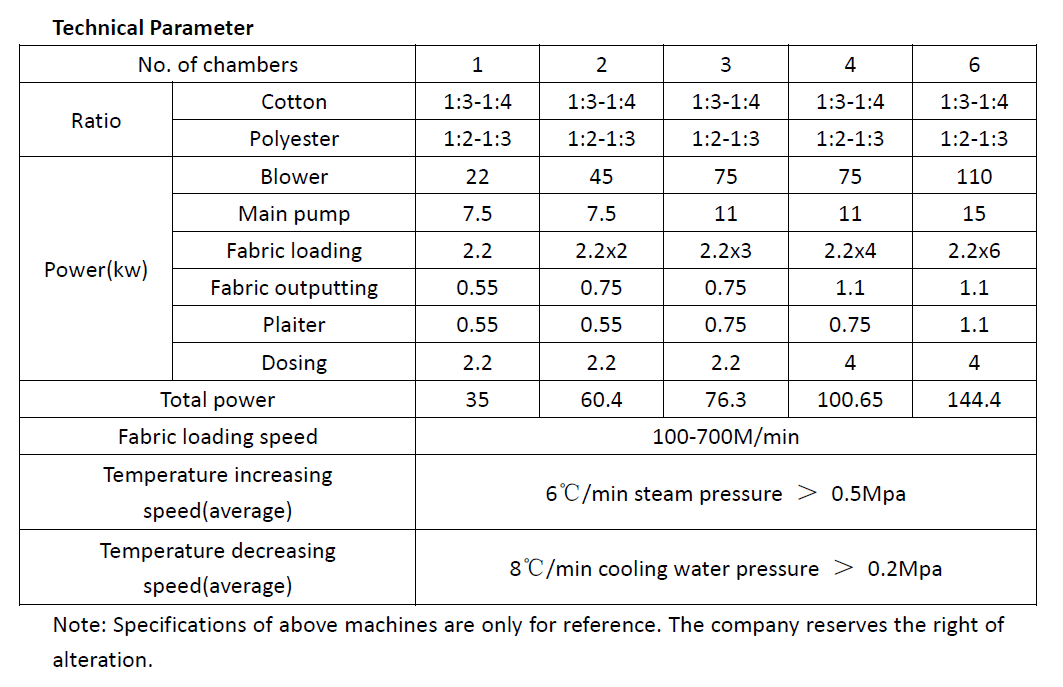

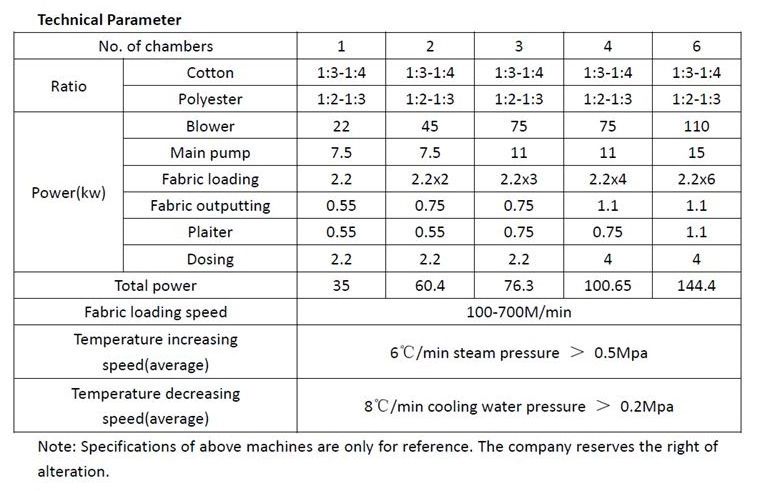

Specification

|

Product Name:

|

High Temperature Airflow Dyeing Machine

|

|

Machine capacity:

|

250kg-1500kg

|

|

Liquor ratio starts at:

|

1:3

|

|

Max temperature:

|

140℃

|

|

Material:

|

Stainless Steel

|

|

Heating mode

|

Steam

|

Product Description

High Temperature Airflow Dyeing Machine

Product Description

High Temperature Airflow Dyeing Machine adopts the aerodynamic theory, it injects the mixed air which is made from blower into the Nozzle of the dyeing machine to run the fabric. The main difference between airflow dyeing machine and traditional overflow dyeing machine is that the former needs neither dyeing liquor nor water to run the fabric. During dyeing process, the air come from blower go into the Nozzles and meet with the dyeing liquor transported by the main pump Nozzle. So that the dyeing liquor is atomized and sprayed to the fabric which is going through the Nozzles, and then it carries the fabric running. Consequently, the fabric will get best dyed. There is no unwelcome crease mark.

This dyeing machine is suitable for all kinds of fabric which can be dyed in traditional dyeing machine, especially for the fabric of high quality and particular demand. Such as follows:

- Single- side reinforced Spandex stretch fabric.

- Fine and high gsm. Plain cloth.

- Fine density pure cotton terry knitted fabric.

- Tight double gossamer mesh fabric.

Special Features

- It’s no need to change the equipment. Any kind of knitted fabric, woven fabric and blended fabric can be bleached and dyed.

- Extremely low liquor ratio: 1:3. Compared to traditional dyeing machine, it saves more than 50% water, and also it saves chemicals, dyestuffs and additives.

-Excellent dyeing effect. The atomized air blows the fabric to keep the fabric running state being changed constantly to decrease creases.

- The unique rinsing way by spraying fresh water allows short processing time with best rinsing effect.

-The fabric is running by air dynamic without hydraulic pressure and dyeing in saturated air accordingly.

- High efficient heating system saves process time and ensures uniform water and steam pressure.

Technical Details

- Main tank & liquor carrying parts are manufactured using stainless steels 316L

- Touch screen controller

- Teflon tube chamber for smooth and secure fabric transport

- Frequency- controlled lifting, plaiter and main pump system.

- 360°Rotary spray rinsing device

- Automatic and programmable touch screen computer

- Automatic temperature control system

- Ration dosing system

- Dyeing liquor atomization nozzle

- Air filter

- Independent control of fabric circulating

- Seam detector is equipped in each chamber.

- Infrared monitoring fabric anti-tangle device

- High efficient heat exchanger

- Glass fiber reinforced plastics working platform

Optional

- Second preparation tank

- 100% Hot water stock tank, preparation of the complete process bath

- Auto self-cleaning filter

- Fast dosing system, bypass function

Hot Searches