- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SDM

-

Model Number:

-

SDMF

-

Product Name:

-

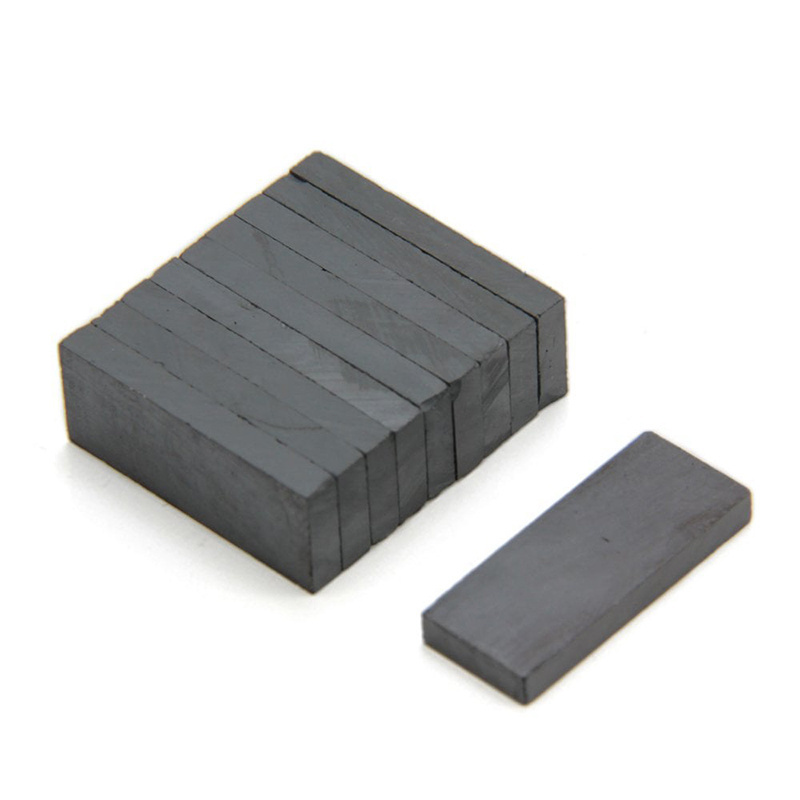

ferrite magnet

-

Certification:

-

ISO9001:2008, ISO/TS16949:2009 and RoHS .

-

Size:

-

customized size Ferrite magnet

-

Material Grade:

-

customized ferrite magnet

-

Max Working Temperature:

-

80-200 Degrees Celsius

-

Density:

-

7.3-7.5 g/cm3

-

Coating:

-

Nickel, Zinc, Epoxy, etc.

Quick Details

-

Tolerance:

-

±1%

-

Grade:

-

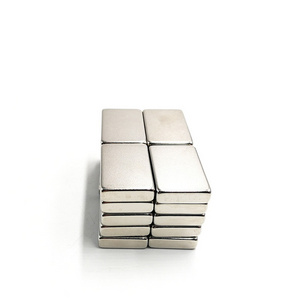

neodymium magnet

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SDM

-

Model Number:

-

SDMF

-

Product Name:

-

ferrite magnet

-

Certification:

-

ISO9001:2008, ISO/TS16949:2009 and RoHS .

-

Size:

-

customized size Ferrite magnet

-

Material Grade:

-

customized ferrite magnet

-

Max Working Temperature:

-

80-200 Degrees Celsius

-

Density:

-

7.3-7.5 g/cm3

-

Coating:

-

Nickel, Zinc, Epoxy, etc.

ferrite magnet

19 Years' Professional Permanent Magnet Manufacturer;

USD $1000000 Alibaba Trade Assurance to Secure Your Transaction

Top 3 Alibaba Permanent Magnet Supplier;

1:). Magnets and Magnetic assemblies are Customized .

2:). Strategic cooperation with China’s No.1 rare earth miner CHINALCO, which enables us strong and safe backup for rare earth raw materials cost stability, 3 x -3% annual price down guaranteed.

3:). ISO/TS 16949, VDA 6.3, ISO9001, ISO14001 certified company, RoHS, REACH, SGS complied product.

4:). 0 PPM performance for General Motor's OEM since 2010, remarkable customers such as SIEMENS, BMW, REGAL BELOIT, NIDEC, , S&T Motiv.

5:). Over 100 million magnets delivered to American, European, Asian and African countries.

6:). One stop service from R&D to mass production.

ferrite magnet rotor

1. Motors, Generators, Sensors, Speakers, Earphones and other musical instruments, Magnetic therapy devices, Magnetic Chuck, Magnetic bearings and couplings, NdFeB Pot Magnet and other magnetic applications.

2. N35-N52, N35M-N50M, N35H-N48H, N35SH-N45SH, N28UH-N42UH, N28EH-N40EH, N28AH-N38AH.

3. Disc, Ring Magnet, Block, Segment, Cylinder, Trapezoid, Customized Design.

4. Ni, Ni-Cu-Ni, Zn(Cr3+), Tin, Epoxy, Ni-Ag, Ni-Au, Passivation, Parylene, etc.

5. Customized size as per your requirements.

6. ISO9001:2008, ISO/TS16949:2009 and RoHS.

1.The Neodymium Magnet and Neodymium Magnetic Assembly we could produce:

2. Customized Neodymium Magnet and Magnetic Assemblies

Neodymium Magnets and Neodymium Magnetic assemblies are Customized. You can tell us the Size, Shape and Grade of the Magnet, we can help you produce in 7-15 days !!

|

Shape |

max.size |

min.size |

|

Block |

240*100*40 |

2*2*1 |

|

Cylinder |

D240*40 |

D2*1 |

|

Ring |

OD240*40 (hole size customized) |

D5*1*1 |

|

Arc |

per your request |

|

|

And other special shape neodymium magnet per your request. |

||

3.More Magnets We Could Produce:

4. Grades, Coatings and Magnetization Direction

(1) Material grades include: N35--N52, N35M--N50M, N35H--N48H, N35SH--N45SH, N28UH--N42UH, N28EH--N40EH.

| Grade | Residual Induction (Br) | Coercive Force (Hcb) | Intrinsic Coercive Force (Hcj) | Max Energy Product (BH)max | Max Working Temp. | ||||

| T | kGs | kA/m | kOe | kA/m | kOe | Kj/m³ | MGOe | (°C) | |

| N35 | 1.17-1.22 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 955 | ≥ 12 | 263-287 | 33-36 | 80 |

| N38 | 1.22-1.25 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 955 | ≥ 12 | 287-310 | 36-39 | 80 |

| N40 | 1.25-1.28 | 12.5-12.8 | ≥ 907 | ≥ 11.4 | ≥ 955 | ≥ 12 | 302-326 | 38-41 | 80 |

| N42 | 1.28-1.32 | 12.8-13.2 | ≥ 915 | ≥ 11.5 | ≥ 955 | ≥ 12 | 318-342 | 40-43 | 80 |

| N45 | 1.32-1.38 | 13.2-13.8 | ≥ 923 | ≥ 11.6 | ≥ 955 | ≥ 12 | 342-366 | 43-46 | 80 |

| N48 | 1.38-1.42 | 13.8-14.2 | ≥ 923 | ≥ 11.6 | ≥ 955 | ≥ 12 | 366-390 | 46-49 | 80 |

| N50 | 1.40-1.45 | 14.0-14.5 | ≥ 796 | ≥ 10 | ≥ 876 | ≥ 11 | 374-406 | 47-51 | 60 |

| N52 | 1.43-1.48 | 14.3-14.8 | ≥ 796 | ≥ 10 | ≥ 876 | ≥ 11 | 390-422 | 49-53 | 60 |

| N35M | 1.17-1.22 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 1114 | ≥ 14 | 263-287 | 33-36 | 100 |

| N38M | 1.22-1.25 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 1114 | ≥ 14 | 287-310 | 36-39 | 100 |

| N40M | 1.25-1.28 | 12.5-12.8 | ≥ 923 | ≥ 11.6 | ≥ 1114 | ≥ 14 | 302-326 | 38-41 | 100 |

| N42M | 1.28-1.32 | 12.8-13.2 | ≥ 955 | ≥ 12 | ≥ 1114 | ≥ 14 | 318-342 | 40-43 | 100 |

| N45M | 1.32-1.38 | 13.2-13.8 | ≥ 955 | ≥ 12.5 | ≥ 1114 | ≥ 14 | 342-366 | 43-46 | 100 |

| N48M | 1.37-1.43 | 13.7-14.3 | ≥ 1027 | ≥ 12.9 | ≥ 1114 | ≥ 14 | 366-390 | 46-49 | 100 |

| N50M | 1.40-1.45 | 14.0-14.5 | ≥ 1033 | ≥ 13 | ≥ 1114 | ≥ 14 | 382-406 | 48-51 | 100 |

| N35H | 1.17-1.22 | 11.7-12.2 | ≥ 868 | ≥ 10.9 | ≥ 1353 | ≥ 17 | 263-287 | 33-36 | 120 |

| N38H | 1.22-1.25 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 1353 | ≥ 17 | 287-310 | 36-39 | 120 |

| N40H | 1.25-1.28 | 12.5-12.8 | ≥ 923 | ≥ 11.6 | ≥ 1353 | ≥ 17 | 302-326 | 38-41 | 120 |

| N42H | 1.28-1.32 | 12.8-13.2 | ≥ 955 | ≥ 12 | ≥ 1353 | ≥ 17 | 318-342 | 40-43 | 120 |

| N45H | 1.32-1.36 | 13.2-13.6 | ≥ 963 | ≥ 12.1 | ≥ 1353 | ≥ 17 | 326-358 | 43-46 | 120 |

| N48H | 1.37-1.43 | 13.7-14.3 | ≥ 995 | 12.5 | ≥ 1353 | ≥ 17 | 366-390 | 46-49 | 120 |

| N35SH | 1.17-1.22 | 11.7-12.2 | ≥ 876 | ≥ 11 | ≥ 1592 | ≥ 20 | 263-287 | 33-36 | 150 |

| N38SH | 1.22-1.25 | 12.2-12.5 | ≥ 907 | ≥ 11.4 | ≥ 1592 | ≥ 20 | 287-310 | 36-39 | 150 |

| N40SH | 1.25-1.28 | 12.5-12.8 | ≥ 939 | ≥ 11.8 | ≥ 1592 | ≥ 20 | 302-326 | 38-41 | 150 |

| N42SH | 1.28-1.32 | 12.8-13.2 | ≥ 987 | ≥ 12.4 | ≥ 1592 | ≥ 20 | 318-342 | 40-43 | 150 |

| N45SH | 1.32-1.38 | 13.2-13.8 | ≥ 1003 | ≥ 12.6 | ≥ 1592 | ≥ 20 | 342-366 | 43-46 | 150 |

| N28UH | 1.04-108 | 10.4-10.8 | ≥ 764 | ≥ 9.6 | ≥ 1990 | ≥ 25 | 207-231 | 26-29 | 180 |

| N30UH | 1.08-1.13 | 10.8-11.3 | ≥ 812 | ≥ 10.2 | ≥ 1990 | ≥ 25 | 223-247 | 28-31 | 180 |

| N33UH | 1.13-1.17 | 11.3-11.7 | ≥ 852 | ≥ 10.7 | ≥ 1990 | ≥ 25 | 247-271 | 31-34 | 180 |

| N35UH | 1.17-1.22 | 11.7-12.2 | ≥ 860 | ≥ 10.8 | ≥ 1990 | ≥ 25 | 263-287 | 33-36 | 180 |

| N38UH | 1.22-1.25 | 12.2-12.5 | ≥ 876 | ≥ 11 | ≥ 1990 | ≥ 25 | 287-310 | 36-39 | 180 |

| N40UH | 1.25-1.28 | 12.5-12.8 | ≥ 899 | ≥ 11.3 | ≥ 1990 | ≥ 25 | 302-326 | 38-41 | 180 |

| N42UH | 1.28-1.32 | 12.8-13.2 | ≥ 899 | ≥ 11.3 | ≥ 1990 | ≥ 25 | 318-342 | 40-43 | 180 |

| N28EH | 1.04-1.08 | 10.4-10.8 | ≥ 780 | ≥ 9.8 | ≥ 2388 | ≥ 30 | 207-231 | 26-29 | 200 |

| N30EH | 1.08-1.13 | 10.8-11.3 | ≥ 812 | ≥ 10.2 | ≥ 2388 | ≥ 30 | 223-247 | 28-31 | 200 |

| N33EH | 1.13-1.17 | 11.3-11.7 | ≥ 836 | ≥ 10.5 | ≥ 2388 | ≥ 30 | 247-271 | 31-34 | 200 |

| N35EH | 1.17-1.22 | 11.7-12.2 | ≥ 876 | ≥ 11 | ≥ 2388 | ≥ 30 | 263-287 | 33-36 | 200 |

| N38EH | 1.22-1.25 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 2388 | ≥ 30 | 287-310 | 36-39 | 200 |

| N40EH | 1.25-1.28 | 12.5-12.8 | ≥ 899 | ≥ 11.3 | ≥ 2388 | ≥ 30 | 302-326 | 38-41 | 200 |

| N28AH | 1.04-1.08 | 10.4-10.8 | ≥ 787 | ≥ 9.9 | ≥ 2624 | ≥ 33 | 207-231 | 26-29 | 230 |

| N30AH | 1.08-1.13 | 10.8-11.3 | ≥ 819 | 10.3 | ≥ 2624 | ≥ 33 | 223-247 | 28-31 | 230 |

| N33AH | 1.13-1.17 | 11.3-11.7 | ≥ 843 | ≥ 10.6 | ≥ 2624 | ≥ 33 | 247-271 | 31-34 | 230 |

| N35AH | 1.17-1.22 | 11.7-12.2 | ≥ 876 | ≥ 11 | ≥ 2624 | ≥ 33 | 263-287 | 33-36 | 230 |

| N38AH | 1.22-1.25 | 12.2-12.5 | ≥ 899 | ≥ 11.3 | ≥ 2624 | ≥ 33 | 287-310 | 36-39 | 230 |

(2) Coating includes Ni-Cu-Ni, Black Nickel, Zn, Sn,Au, Ag,Black Epoxy, Phosphated, Parylene, etc.

(3) Magnetization directions include: