- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

9000 KG

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

Customizd

-

Type:

-

Shot Blasting Machine Equipment

-

Color:

-

customiza

-

Application:

-

Steel Plate Surface Cleaning

-

Function:

-

Surface cleaning of steel plate

-

Machine:

-

blasting cleaning machine

-

Certification:

-

ce

-

Name:

-

H Beam shot blasting machine price

Quick Details

-

Place of Origin:

-

Shandong, China (Mainland)

-

Brand Name:

-

puhua

-

Marketing Type:

-

Hot Product 2023

-

Weight (KG):

-

9000 KG

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

Customizd

-

Type:

-

Shot Blasting Machine Equipment

-

Color:

-

customiza

-

Application:

-

Steel Plate Surface Cleaning

-

Function:

-

Surface cleaning of steel plate

-

Machine:

-

blasting cleaning machine

-

Certification:

-

ce

-

Name:

-

H Beam shot blasting machine price

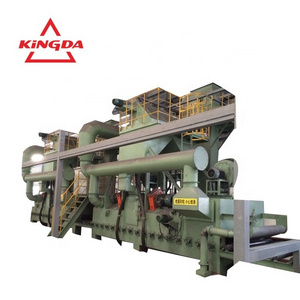

Roller conveyor steel plate Shot Blasting Machine With Different Models

Roller conveyor shot blasting machines are used to remove scale and rust from metal profiles and sheet metal components. By combining a roller conveyor with the appropriate crossover conveyors, individual process steps such as blasting, conservation, sawing and drilling can be interlinked. This ensures a flexible manufacturing process and high material output.

We can customize all kinds of shot blasting machines for you according to your requirements.

|

Type

|

Q69(customizable)

|

|

The effective cleaning width(mm)

|

800-4000

|

|

The room feed-in size(mm)

|

1000*400---4200*400

|

|

The length of cleaning workpiece(mm)

|

1200-12000

|

|

The speed of wheel conveyer(m/min)

|

0.5-4

|

|

The thicksness of cleaning steelsheet(mm)

|

3-100---4.4-100

|

|

The section steel specification(mm)

|

800*300---4000*300

|

|

The quantity of shot blasting(kg/min)

|

4*180---8*360

|

|

The first enclosed quantity(kg)

|

4000---11000

|

|

Roll brush adjusting height(mm)

|

200---900

|

|

Airness capacity(m³/h)

|

22000---38000

|

|

Exterior size(mm)

|

25014*4500*9015

|

|

Total power(except for dust cleaning)(kw)

|

90---293.6

|

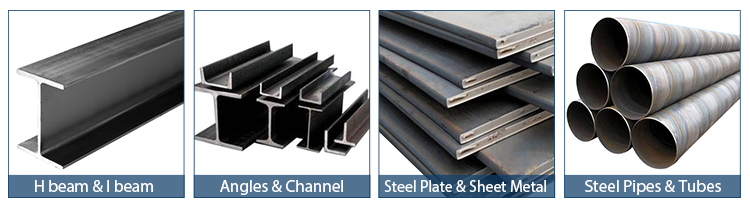

Application:

1. Remove scale and rust from metal profiles and sheet metal components.

2. Surface treatment for H beam, Steel Plate, sections, angles, pipes and others.

3. Blast cleaning of complex welding constructions where all surfaces are cleaned. For example head- and base-plates, welded ribs and re-enforcements must be de-scaled and de-rusted. And the welding seams must be cleaned.

4. Typical areas of application: Steel and shipbuilding, automobile, motorcycle, bridge, machine.

Loading capacity: 2 tons per meter.

Rollers Distance: 1 m.

Rollers Speed: 0.5-4 m per min.

Drive: Variable speed reducer.

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

Auxiliary Blasting Chamber: Four layers rubber curtains

Main Blasting Chamber: blasting wheels are mounted on chamber in different angles

Control Unit: PLC .

P L C: Siemens, Omron or famous reliable brand in China for your choice.

Emergency Stop: on main control panel and rollers conveyors.

Power Indicator: available on control panel .

. The fan power is 30 kw, ventilation quantity is 26000 m3/h.

We supply overseas service, engineer can go to your place guide installation and debugging.

5. What work part can clean by this machine?