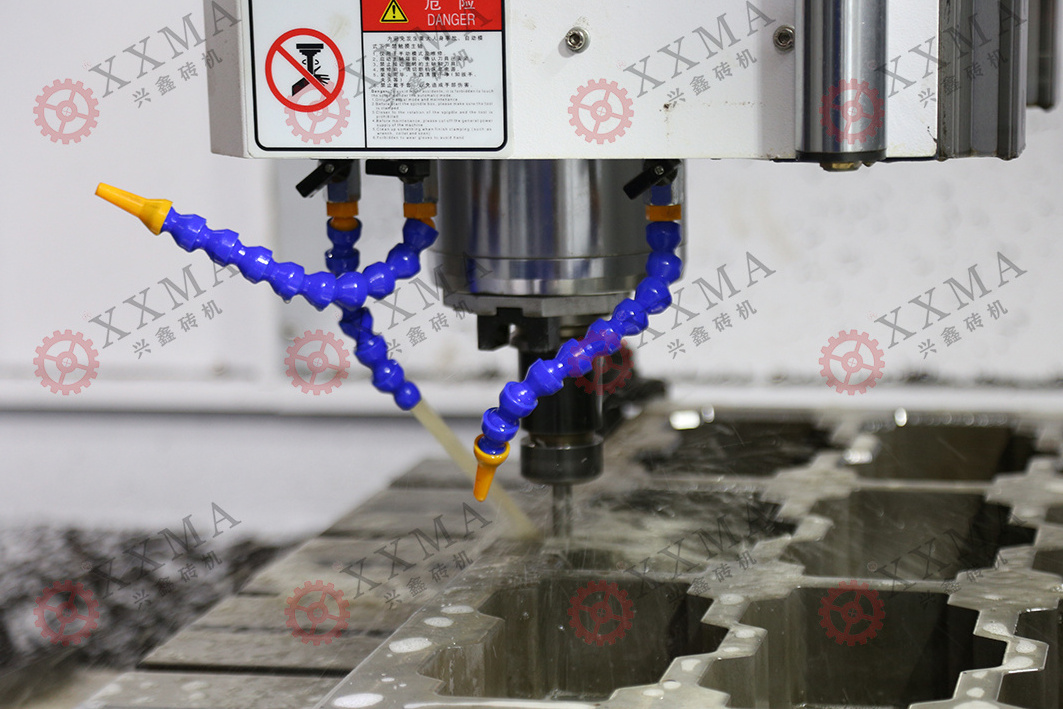

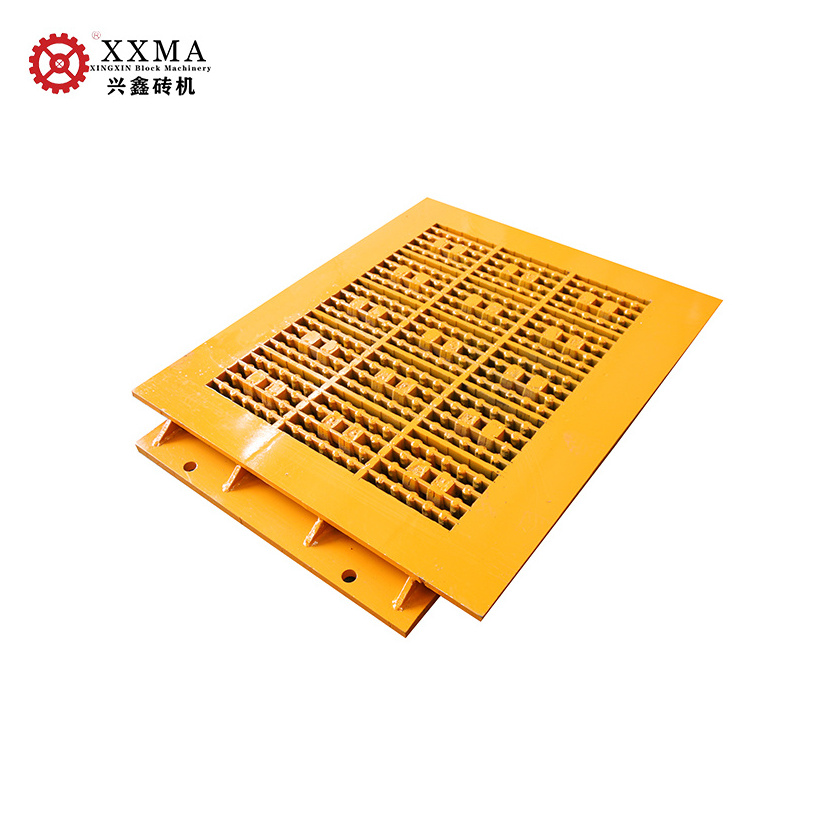

High-heat treatment special technology( to make the mold more durable and firm)

- Product Details

- {{item.text}}

Quick Details

-

Customer Design:

-

Accept

-

Life Time:

-

Above 100,000 cycles

-

Usage:

-

concrete block mold for making bricks

-

Mould Forming method:

-

Linear Cutting

-

Raw materia:

-

Q345B High manganese steel

-

Application:

-

Garden Decoration

-

Color:

-

Customized Color

-

Surface treatment:

-

other

-

Keyword:

-

Mould Maker

-

Mould Life:

-

1 year

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

XINGXIN

-

Customer Design:

-

Accept

-

Life Time:

-

Above 100,000 cycles

-

Usage:

-

concrete block mold for making bricks

-

Mould Forming method:

-

Linear Cutting

-

Raw materia:

-

Q345B High manganese steel

-

Application:

-

Garden Decoration

-

Color:

-

Customized Color

-

Surface treatment:

-

other

-

Keyword:

-

Mould Maker

-

Mould Life:

-

1 year

Product Overview

As a “

National Inspection-free Product

”, Xingxin block machinery is well supported with complete functions, easy operation and stable quality.

The blocks produced are featured with high consistency, good capabilities in frost-resistance, permeability-resistance, sound insulation, thermal insulation, heat-preservation property and reliable performance.

The blocks produced are featured with high consistency, good capabilities in frost-resistance, permeability-resistance, sound insulation, thermal insulation, heat-preservation property and reliable performance.

FEATURES AT A GLANCE

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

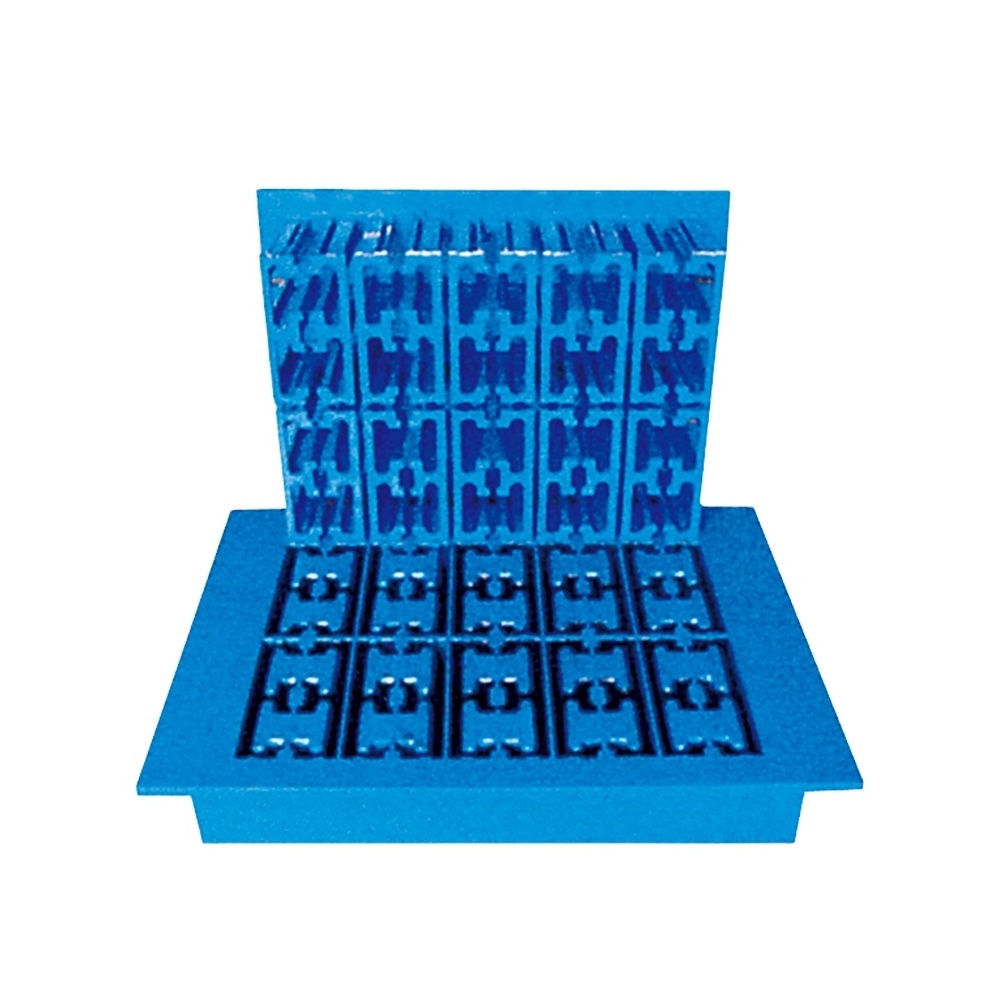

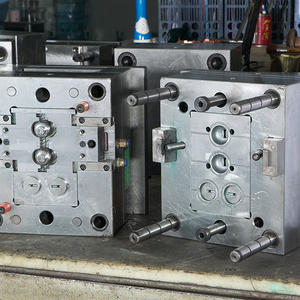

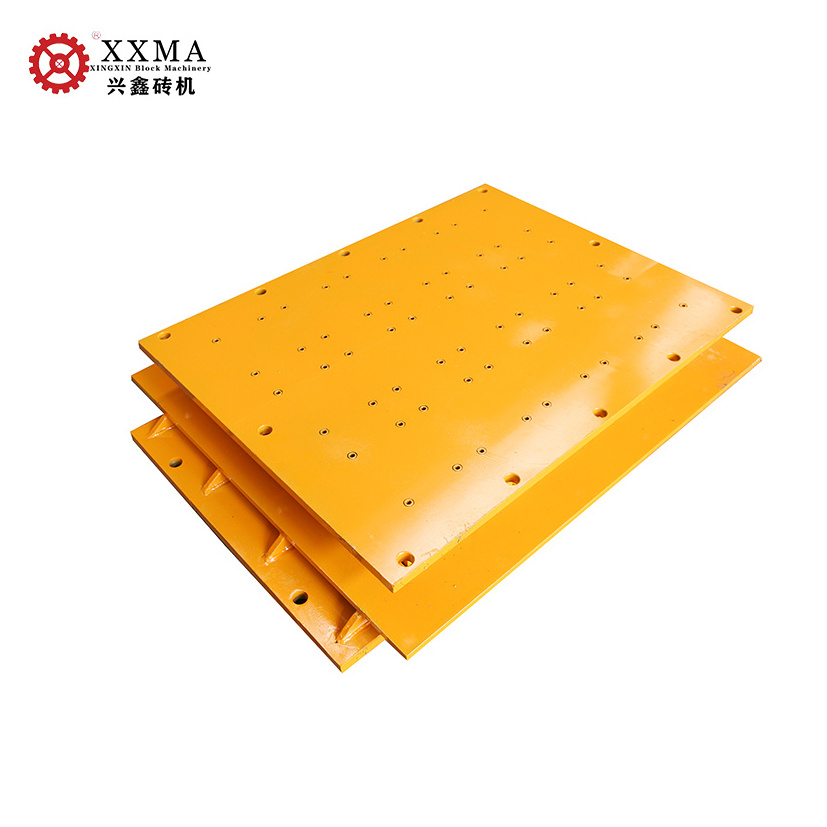

1. Molds and tamper head plates are manufactured with state of the art milling technology, Highest possible milling and case hardening techniques produce an excellent mold;

2. Exact tolerances of the tamper head shoes and the insert allow efficient and precise assembly;

3. Adopting Q345B High manganese steel with High-heat Treatment Special Technology, the service life can be over 100,000 times;

4. The mold fit the deck plate well, low wear and tear, fast distribution of raw material, take off fluently;

2. Exact tolerances of the tamper head shoes and the insert allow efficient and precise assembly;

3. Adopting Q345B High manganese steel with High-heat Treatment Special Technology, the service life can be over 100,000 times;

4. The mold fit the deck plate well, low wear and tear, fast distribution of raw material, take off fluently;

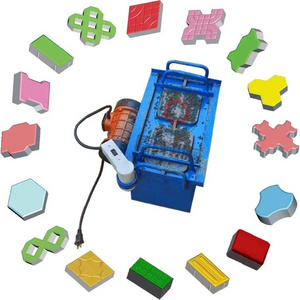

PRODUCT CONFIGURATION

Matching machine

FAQ

Q1: what are our advantages?

A: Almost 30 years experience, so we can provide more professional suggestion, installation, training service for you. With 10

years trading experience, our products have been exporting to over 30 countries.

Q2: What kind of products we can supply ?

A: Auto concrete brick making machine, Auto hydraulic brick making machine, Free pallet automatic block forming machine, Concrete

mixer, Batching machine, Stacker, Cuber, etc.

Q3:How to make different size and shape brick by one machine?

A: By changing mould it can produce all types of standard building blocks.

Q4:How about installation service?

A: We have experienced engineers, they could come to your place to direct the installation and give the operation training.

Q5:How about After sale service?

During the 1st year, we will supply followings for free:

1. Spare parts of machine and equipment (except quick-wear parts)

2. Repair for equipment’s broken (design, work process and production)

A: Almost 30 years experience, so we can provide more professional suggestion, installation, training service for you. With 10

years trading experience, our products have been exporting to over 30 countries.

Q2: What kind of products we can supply ?

A: Auto concrete brick making machine, Auto hydraulic brick making machine, Free pallet automatic block forming machine, Concrete

mixer, Batching machine, Stacker, Cuber, etc.

Q3:How to make different size and shape brick by one machine?

A: By changing mould it can produce all types of standard building blocks.

Q4:How about installation service?

A: We have experienced engineers, they could come to your place to direct the installation and give the operation training.

Q5:How about After sale service?

During the 1st year, we will supply followings for free:

1. Spare parts of machine and equipment (except quick-wear parts)

2. Repair for equipment’s broken (design, work process and production)

Contact us

Hot Searches