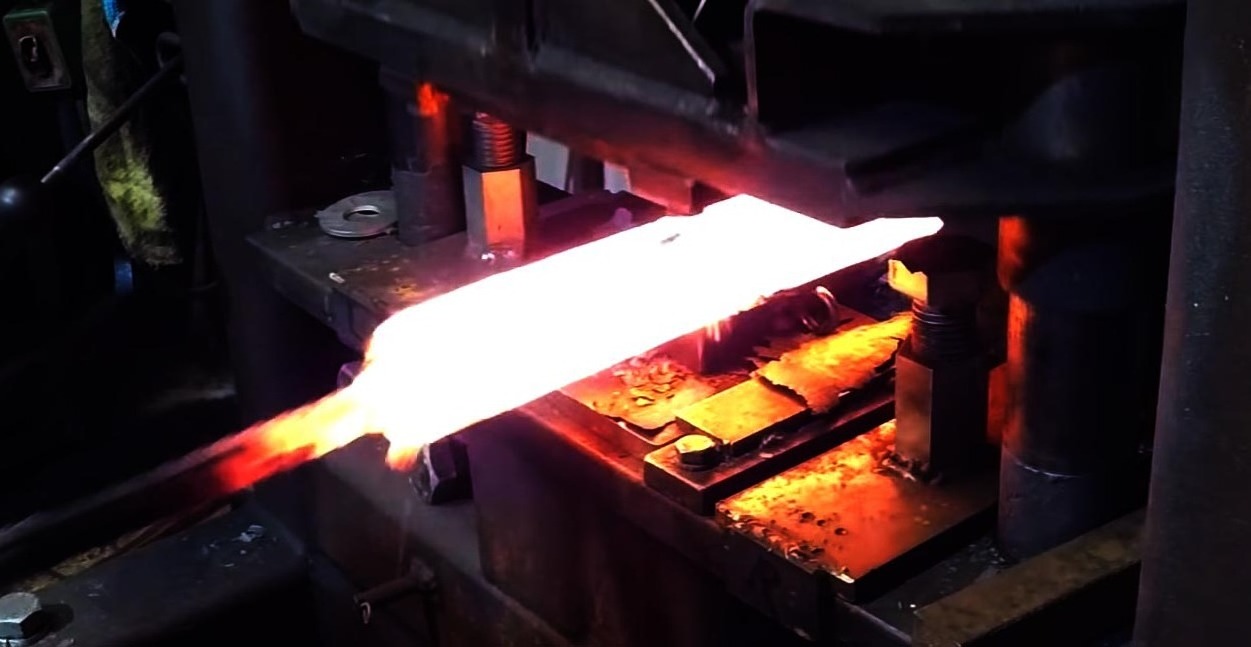

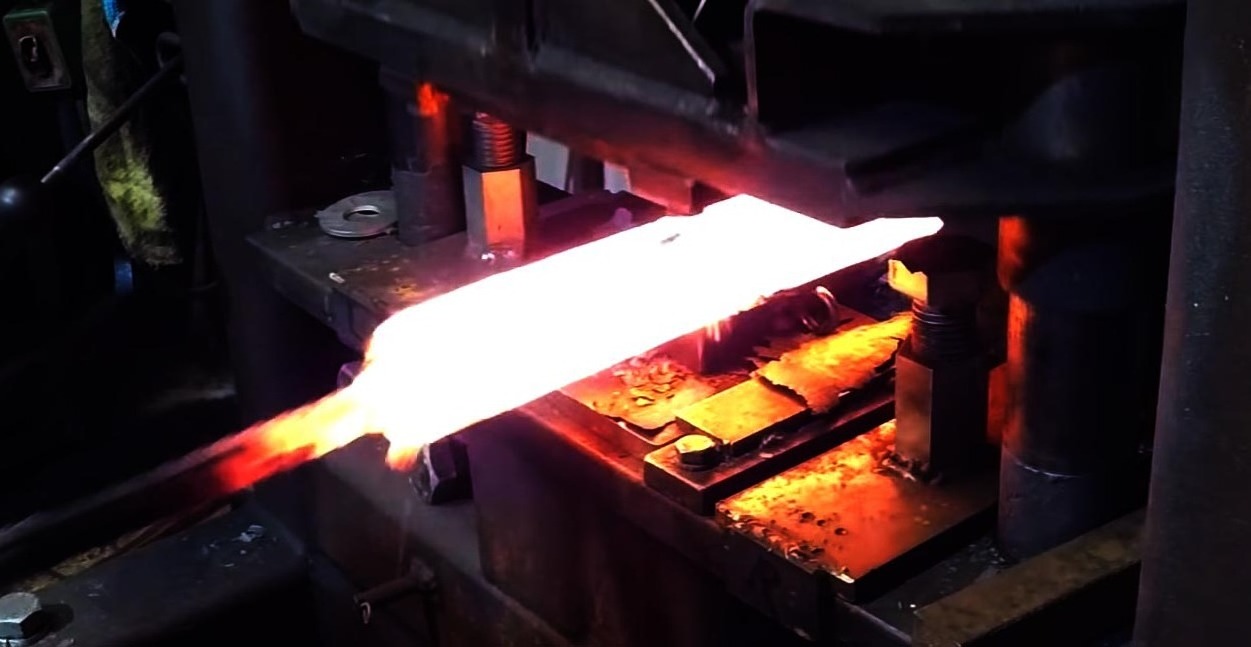

Billets are first welded with each other to get a desired pattern on the Damascus Steel Bars.

Our Damascus Steel contain 1095 carbon steel and 15N20 steel, forged & welded. The blade has hardness 55-52 HRC and has 376 layers.

It is forged in a specific way to achieve high hardness, beautiful & unique blade patterns. We have different patterns in Damascus Steel like Twist, Ladder, Rain Drop, Straight, Fire, Mosaic, Cross, Star etc.

|

Damascus Steel Bar / Billets for Knife Making

|

|

|

|

|||

|

Steel Type

|

|

Damascus Steel ( 1095 & 15n20 - 376 Layers )

|

|

|||

|

Product

|

|

Custom Handmade Damascus Steel Billets Bars

|

|

|||

|

Blade Hardness

|

|

50-52 HRC

|

|

|||

|

Blade Pattern

|

|

Twist

|

|

|||

|

Bar Length

|

|

11 Inches

|

|

|||

|

Bar Width

|

|

2 Inches

|

|

|||

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Billets are first welded with each other to get a desired pattern on the Damascus Steel Bars.

They they go into the hammer press where they are forged and folded multiple times to get 376 layers on the steel.

It is forged in a specific way to achieve high hardness.

Flattened, Grounded. Then a bit of more forge welding. The stack of steel is formed into a billet, and then Damascus Billet or Damascus Bar are then used to make a Knife.

|

Packaging

|

|

|

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

|

Weight

|

1.2 T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|