- Product Details

- {{item.text}}

Quick Details

-

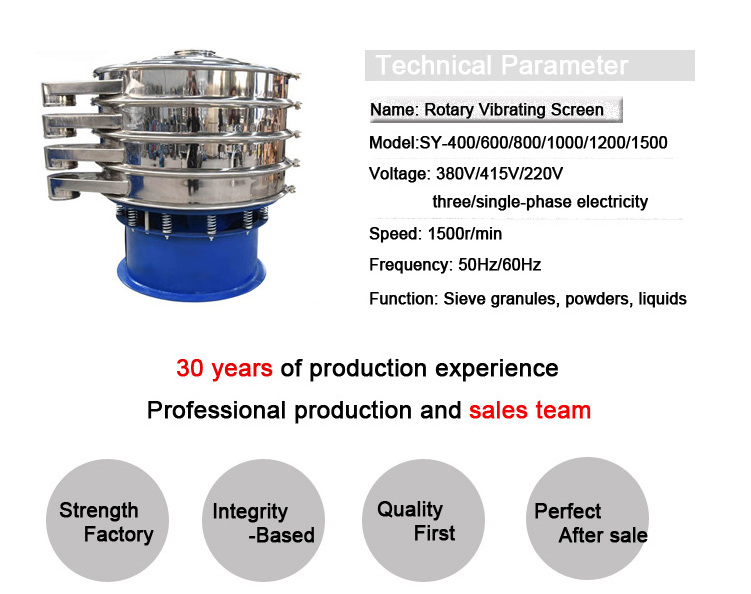

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

Choose

-

Weight:

-

130 KG

-

Material:

-

round grain sifter vibrating screen classifier dry sifting machine

-

Keyword:

-

Vibrating sieve filter

-

Function:

-

Grading/Classifying

-

Diameter:

-

400-1500 mm

-

Cleaning system:

-

Bouncing Balls

-

Layer:

-

1-4 Layers

-

Capacity:

-

100Kg-1500 kg/hour

-

Driving force:

-

Electricity

-

Surface Treatment:

-

Mirror polishing or wire drawings

-

Customized:

-

Add Wheel / hopper/gate

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SANYUANTANG

-

Voltage:

-

220V/380V/415V/450V

-

Dimension(L*W*H):

-

Choose

-

Weight:

-

130 KG

-

Material:

-

round grain sifter vibrating screen classifier dry sifting machine

-

Keyword:

-

Vibrating sieve filter

-

Function:

-

Grading/Classifying

-

Diameter:

-

400-1500 mm

-

Cleaning system:

-

Bouncing Balls

-

Layer:

-

1-4 Layers

-

Capacity:

-

100Kg-1500 kg/hour

-

Driving force:

-

Electricity

-

Surface Treatment:

-

Mirror polishing or wire drawings

-

Customized:

-

Add Wheel / hopper/gate

Product Description

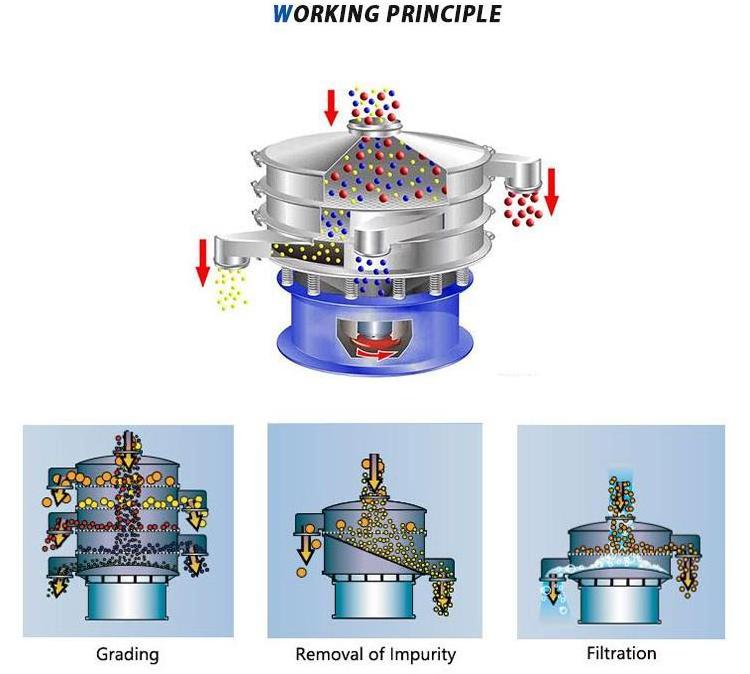

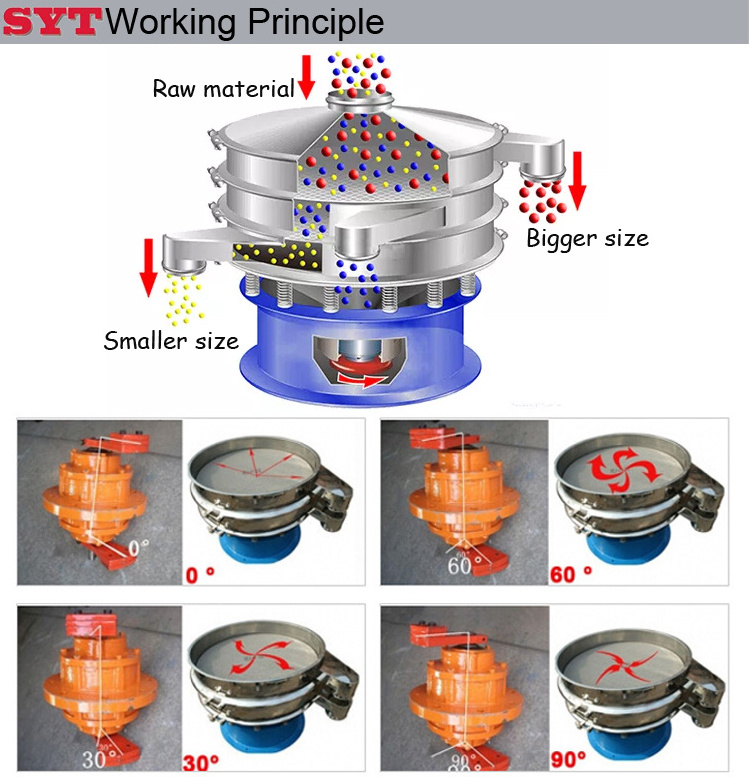

Principle of rotary vibrat screen:

Rotary vibrat screen classifier is a high precision fine powder screening machine. The working principle of vibrating screen is that the unbalanced weight dropper installed on the top and bottom ends of motor to change the rotation motion of motor to horizontal,vertical and inclined three-dimensional motions, and then passes this motion to screen surface, achieving the purpose of classification, filtering and removing impurities.

Working principle

|

Model

|

Effective diameter

|

Screen size

|

Layer

|

Power(KW)

|

|

SY-400

|

380 mm

|

2-500 mesh

|

1-3 layers

|

0.25 kw

|

|

SY-600

|

580 mm

|

|

1-3 layers

|

0.55 kw

|

|

SY-800

|

780 mm

|

|

1-4 layers

|

0.75 kw

|

|

SY-1000

|

970 mm

|

|

1-4 layers

|

1.1 kw

|

|

SY-1200

|

1170 mm

|

|

1-5 layers

|

1.5 kw

|

|

SY-1500

|

1470 mm

|

|

1-5 layers

|

2.2 kw

|

|

SY-1800

|

1770 mm

|

|

1-5 layers

|

3 kw

|

Fine Screening Machine - Rotary Vibration Sieve Shaker

1.

Filtration

:Remove the particles from the liquid.

2. Grading :Classification is put powder and particles of different sizes into particles. With 1 to 5 layers of screens, one three decks vibrating screen can separate 4 size the particle continuously,and have the narrow particle size range control.

3. Impurity :In high flow process, the machine can remove large particles or particles with lower percentage quickly.

2. Grading :Classification is put powder and particles of different sizes into particles. With 1 to 5 layers of screens, one three decks vibrating screen can separate 4 size the particle continuously,and have the narrow particle size range control.

3. Impurity :In high flow process, the machine can remove large particles or particles with lower percentage quickly.

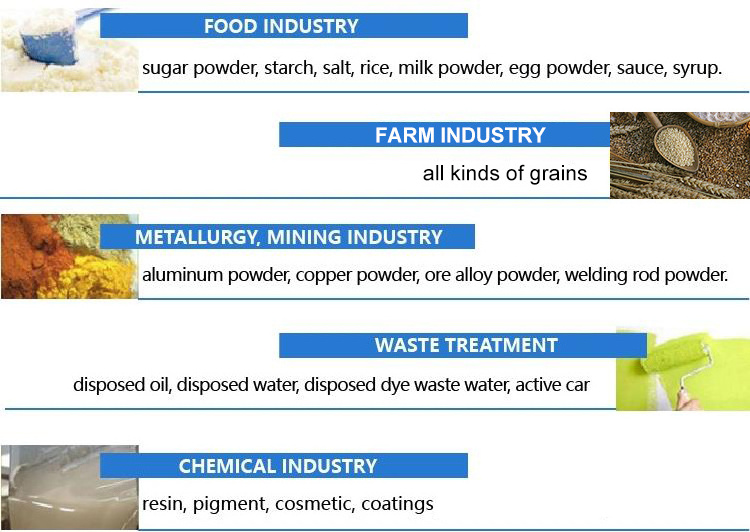

Application Field

Recommend Products

Related Products

Company Introduction

Xinxiang Sanyuantang Machine Co., Ltd. is located in Xinxiang High-tech Industrial Zone. It is a large-scale vibration equipment enterprise integrating scientific research, production and sales. In 2016, it passed the ISO 9001 international quality management system certification. The company is committed to the production and sales of vibrating screen equipment, conveying and lifting equipment. Our products mainly include gyratory screen , tumbler screening machine, rotary vibrating screen, ultrasonic vibrating screen, linear vibrating screen, filter sieve, air flow sieve,lab test sieve shaker, and a series of products such as conveying and lifting equipment.

FAQ

Q:What is the real delivery time of your factory?

Q: How do your after-sale service work if the product got damaged?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost,

we would wait for the customer's bill for the fixed cost and refund this part of cost.

(Note: Vulnerable parts do not include. If you are interested in our products, please feel free to send me an inquiry or contact any time. I will provide you with the best service and the most favorable price.

Q.

How To Choose Suitable Model?

1. If you have ever used the screen machine, kindly please tell us its DIAMETER, LAYERS, MESH SIZES, MATERIALS.

2. If never use the machine until now, please offer us the info about material as below:

1> Material name: _____, bulk density :_____kg/m³ or ____g/cm³, and water content about _____%.

2> Capacity required___kg/h

3> How many layers?____ layers.

4>The mesh size for each layer: ____ mm, ____ mm, ____ mm. Or ____ mesh, ____ mesh, ____ mesh.

5> Voltage and frequency:____V, ___HZ, 3 phase

6> Sea port name or address for shipment.

2> Capacity required___kg/h

3> How many layers?____ layers.

4>The mesh size for each layer: ____ mm, ____ mm, ____ mm. Or ____ mesh, ____ mesh, ____ mesh.

5> Voltage and frequency:____V, ___HZ, 3 phase

6> Sea port name or address for shipment.

Contact Sanyuantang customer service

Hot Searches