- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Size:

-

Customized

-

Material:

-

Customized

-

Weight:

-

Customized

-

Voltage:

-

Customized

-

Heating element:

-

Type 1800 silicon molybdenum rod

-

Heating rate:

-

≤ 20 ℃/Min

-

Recommended rate of temperature rise:

-

≤ 10 ℃/Min

-

Control precision:

-

+/- 1 ℃

-

Thermocouple Type:

-

B

-

Vacuum degree:

-

-0.1MPa

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

LITH

-

Model Number:

-

LITH-1700atmosphere

-

Place of Origin:

-

Fujian, China

-

Size:

-

Customized

-

Material:

-

Customized

-

Weight:

-

Customized

-

Voltage:

-

Customized

-

Heating element:

-

Type 1800 silicon molybdenum rod

-

Heating rate:

-

≤ 20 ℃/Min

-

Recommended rate of temperature rise:

-

≤ 10 ℃/Min

-

Control precision:

-

+/- 1 ℃

-

Thermocouple Type:

-

B

-

Vacuum degree:

-

-0.1MPa

High Temperature 1800C 1700C 1600C 1400C 1200C Atmosphere Gas Muffle Box Furnace With 50 Segments Program Temperature Control

Introduction

This atmosphere box furnace uses 1800 type silicon molybdenum rod as heating element, double-layer shell structure and 50-stage program temperature control system, phase shift trigger, thyristor control, furnace polycrystalline fiber material, double layer The furnace shell is equipped with an air-cooling system, which can quickly and gently raise and lower the temperature. The whole shell is sealed, the cover plate and the furnace door are sealed with a high-temperature silicone O-ring, and the furnace door is equipped with a water-cooling system. The gas enters through multiple inlet pipes. From the door of the furnace, it can pass hydrogen, argon, nitrogen, ammonia decomposition gas, carbon monoxide and other gases, and can pre-vacuate. The furnace has the advantages of temperature field equilibrium, low surface temperature, fast temperature rise and fall, energy saving, etc. Research institutes, industrial and mining enterprises are ideal products for atmosphere protection and sintering and atmosphere reduction.

1. Door opening protection system: The furnace is equipped with a travel switch, which automatically cuts off the power when the furnace door is opened, effectively ensuring the safety of the user.

2. Sealing system: The top cover and the furnace door (other places have been welded) are sealed with silicone O-rings, easy to remove and remove, can be repeatedly removed, air tight, can guarantee 8 hours pressure gauge pointer Not deflected.

3. Vacuum system (optional): The atmospheric chamber furnace can be pre-vacuumed to accelerate the cleaning of the air inside the furnace.

4. Furnace material: It adopts alumina fiber furnace material, which does not drop powder, has good heat preservation performance, high reflectivity, balanced temperature field, and strong resistance to heat expansion and contraction.

5. Heating elements: All use 1800 type Dia7mm heating rod, the rod surface load is low, long service life.

6. Leakage protection function: The furnace is equipped with a leakage air switch, which automatically cuts off the power when the furnace body leaks to ensure the safety of use.

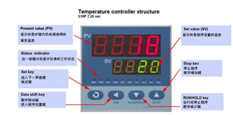

7. Using Yudian program temperature control instrument

1) 50-stage program temperature control can only be adjusted by PID.

2) With over-temperature protection, the electric furnace heating circuit is automatically cut off when the temperature is over-temperature or broken, (when the electric furnace temperature exceeds 1720 degrees or the thermocouple is blown, the AC relay on the main circuit will be automatically disconnected, the main circuit is broken. On, the ON light on the panel is off, the OFF light is on, and the limited protection electric furnace).

3) With 485 communication interface (standard when purchasing software)

4) It has the function of power-off protection, that is, when the furnace is powered on after the power is cut off, the program does not rise from the starting temperature, but rises from the temperature when the power is turned off.

5) The meter has the function of temperature self-tuning

8. Installation conditions:

1) Power supply 220V 50HZ 40A air switch.

2) A plastic water tank is needed (a supermarket can buy it), and the company is equipped with a submersible pump and a water pipe.

3) Steel cylinders, pressure reducing valves, and intake piping customers are equipped with their own.

Specifications

|

Power |

7KW |

Standard configuration |

|

Chamber size |

300X200X200(DXWXH) other sizes available |

Furnace door brick: 1 block

High temperature gloves: 1 pair

Clamps: 1

Alumina tile: 1 block

Submersible pump: 1 set (including pipe) |

|

Supply voltage |

220V |

|

|

Phase |

single phase |

|

|

Heating element |

Type 1800 silicon molybdenum rod |

|

|

Control mode |

50 segments of program temperature control |

|

|

Chamebr material |

Model 1800 alumina polycrystalline fiber |

|

|

Heating rate |

≤ 20 ℃/Min |

|

|

Recommended rate of temperature rise |

≤ 10 ℃/Min (can be designed according to customer requirements) |

|

|

Control precision |

+/- 1 ℃ |

|

|

Thermocouple Type |

B |

|

|

Maximum temperature |

1700 ℃ |

|

|

Vacuum degree |

-0.1MPa |

|

|

Rated temperature |

1600 ℃ |

|

|

Peripheral surface temperature |

less than 45 ℃ |

|

|

Trigger |

Phase shift trigger (with soft start and current limit function) Current limiting function: No matter how to adjust the heating time, the secondary current of our electric furnace after passing through the transformer is limited to 160A, which has limited protection of the equipment, no matter how you operate, it will not burn out the equipment.

Soft start function: the current will increase slowly when starting up, and the impact on the heating element is small, which is beneficial to the extension of the life of the heating element. When the current exceeds 1.5 times the set current, the trigger will automatically turn off, and the protection circuit |

|

|

Silicon controlled |

SEMIKRON 106/16E |

Product Image