- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Can be customized according to your plant

-

Weight:

-

1000 KG

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

220/380V 50/60Hz

-

Power:

-

5kw

-

Product name:

-

Carton packing system

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Function:

-

Forming, filling, sealing, strapping, palletizing

-

Suitable for:

-

Carton/box packing line

-

Carton/box erector:

-

12/22 per minute

-

Small box fill into big carton:

-

2-3 carton/min, max. 6 boxes per layer, max. 2 layers,

-

Carton tape sealing and strapping:

-

12-22 per minute

-

Labelling:

-

20-40 per minute

-

Palletizing:

-

3-5 carton/min, max. 10 layers

-

Warranty Period:

-

1 year

Quick Details

-

Machinery Capacity:

-

2-3 carton/min

-

Brand Name:

-

Focus Machinery

-

Year:

-

2023

-

Dimension(L*W*H):

-

Can be customized according to your plant

-

Weight:

-

1000 KG

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

220/380V 50/60Hz

-

Power:

-

5kw

-

Product name:

-

Carton packing system

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Function:

-

Forming, filling, sealing, strapping, palletizing

-

Suitable for:

-

Carton/box packing line

-

Carton/box erector:

-

12/22 per minute

-

Small box fill into big carton:

-

2-3 carton/min, max. 6 boxes per layer, max. 2 layers,

-

Carton tape sealing and strapping:

-

12-22 per minute

-

Labelling:

-

20-40 per minute

-

Palletizing:

-

3-5 carton/min, max. 10 layers

-

Warranty Period:

-

1 year

Products Description

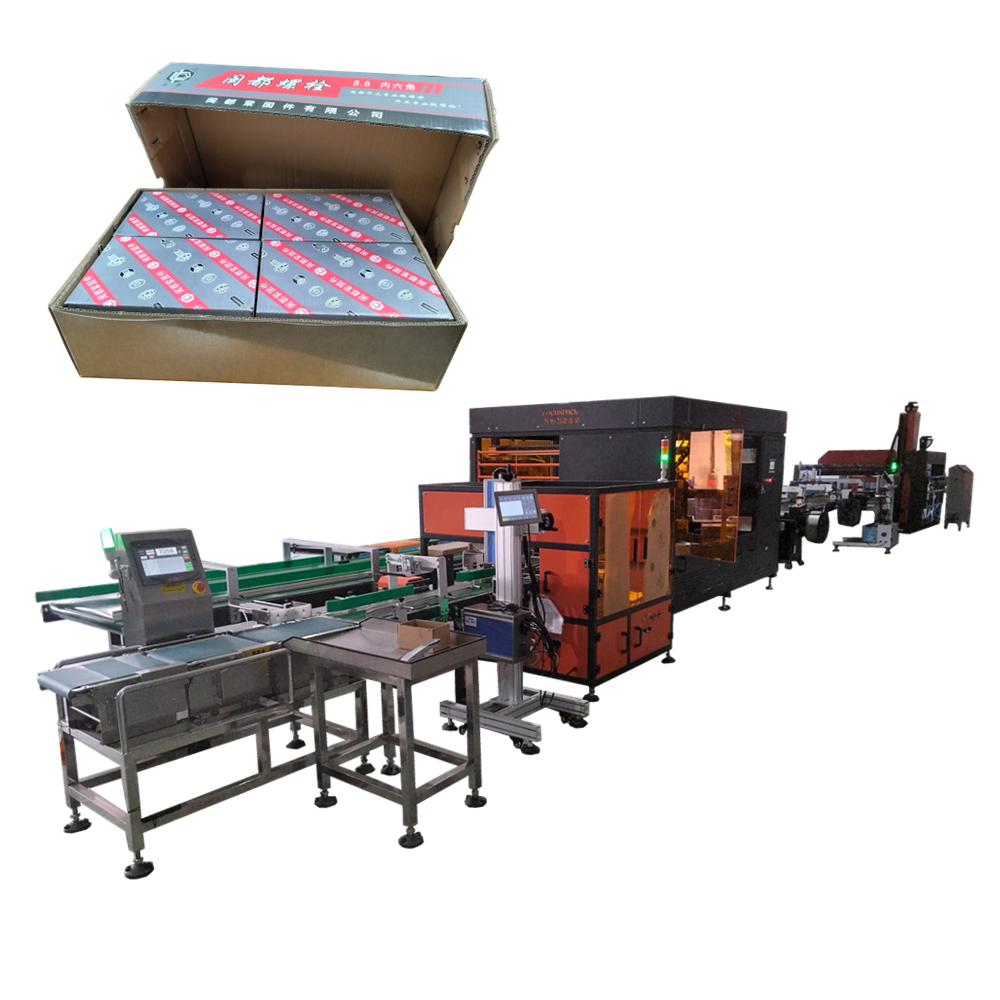

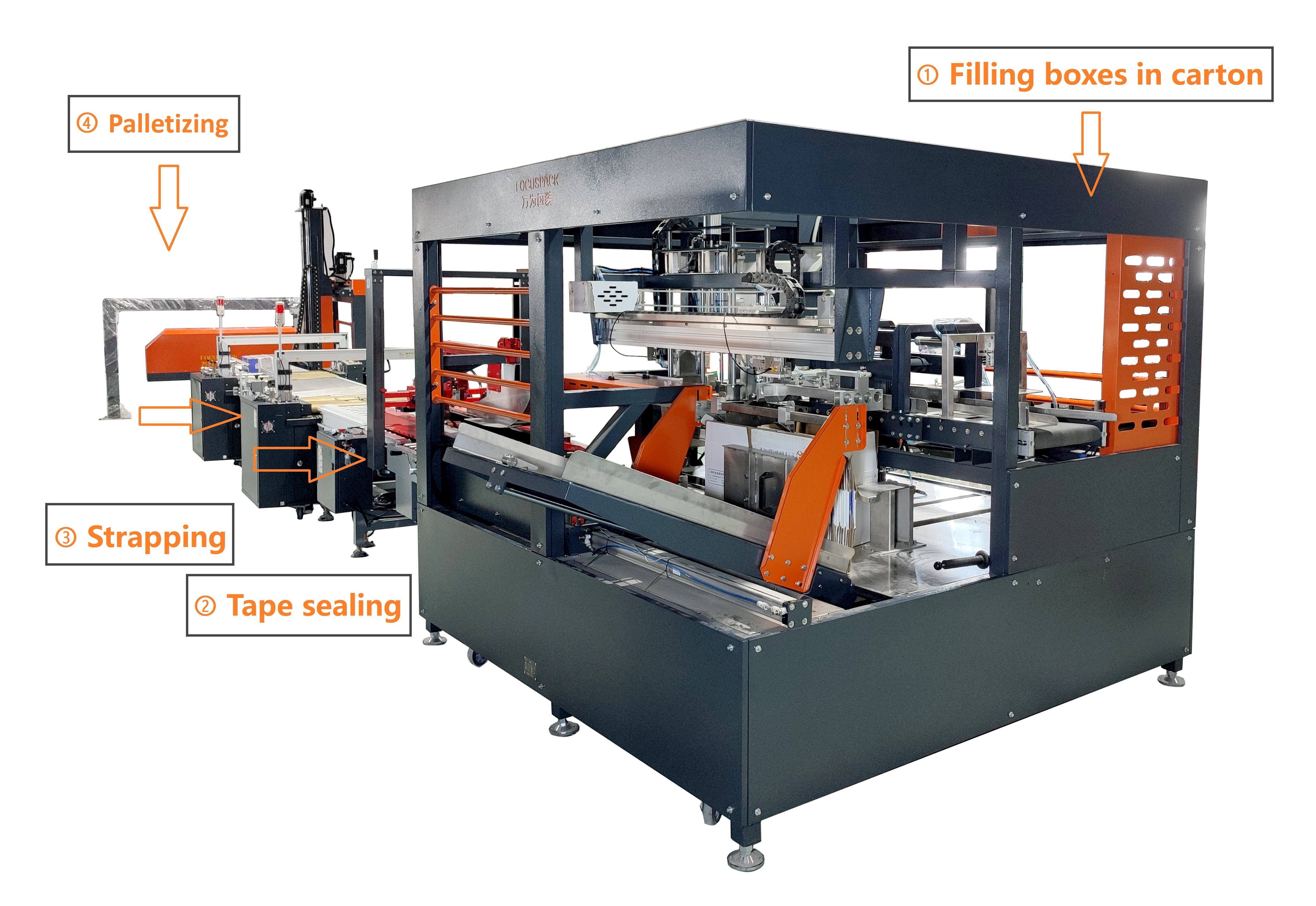

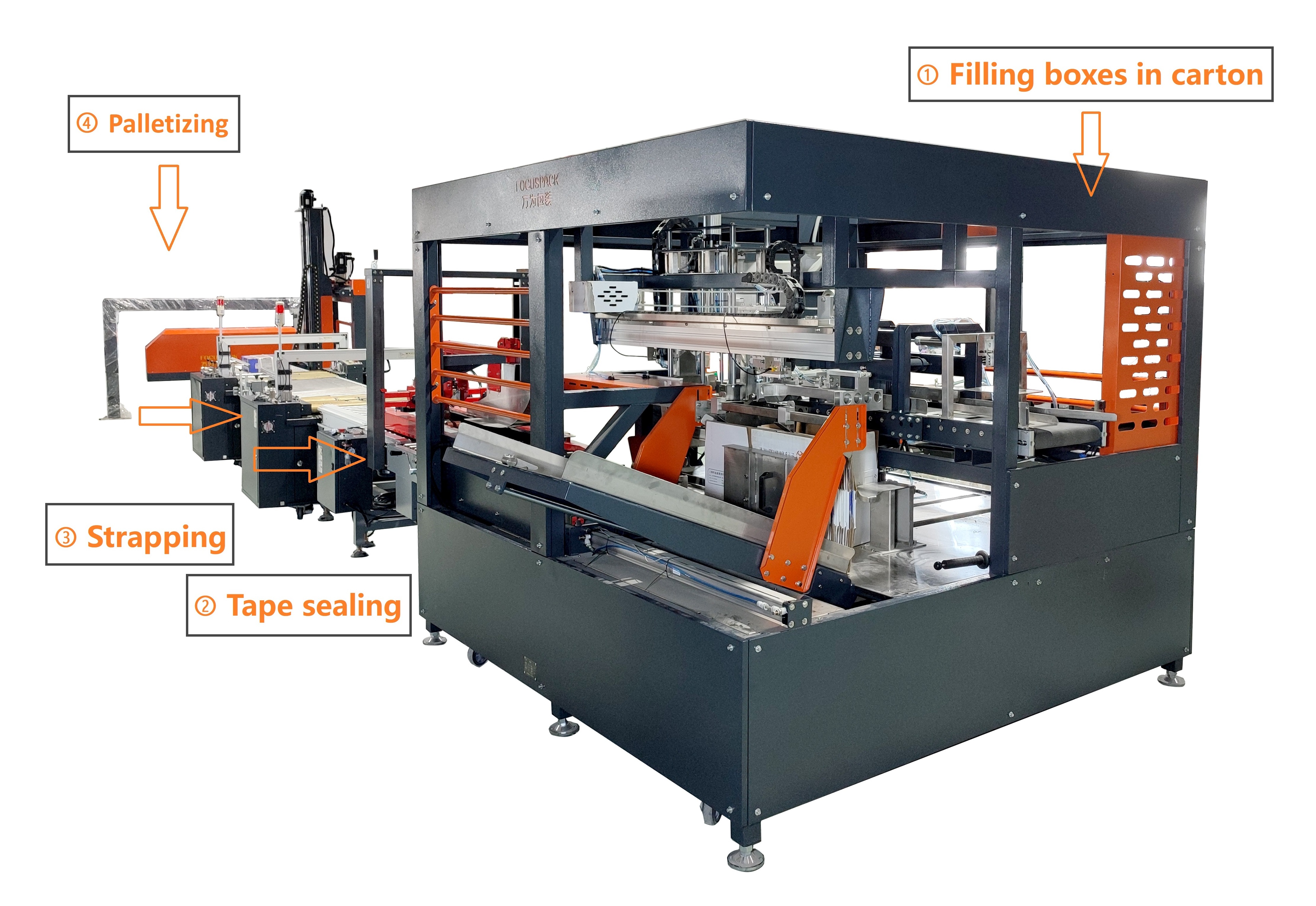

AUTOMATIC CARTON PACKING LINE

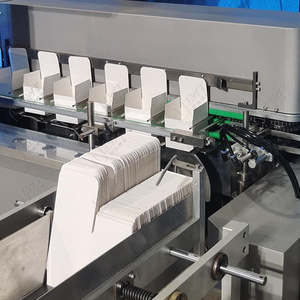

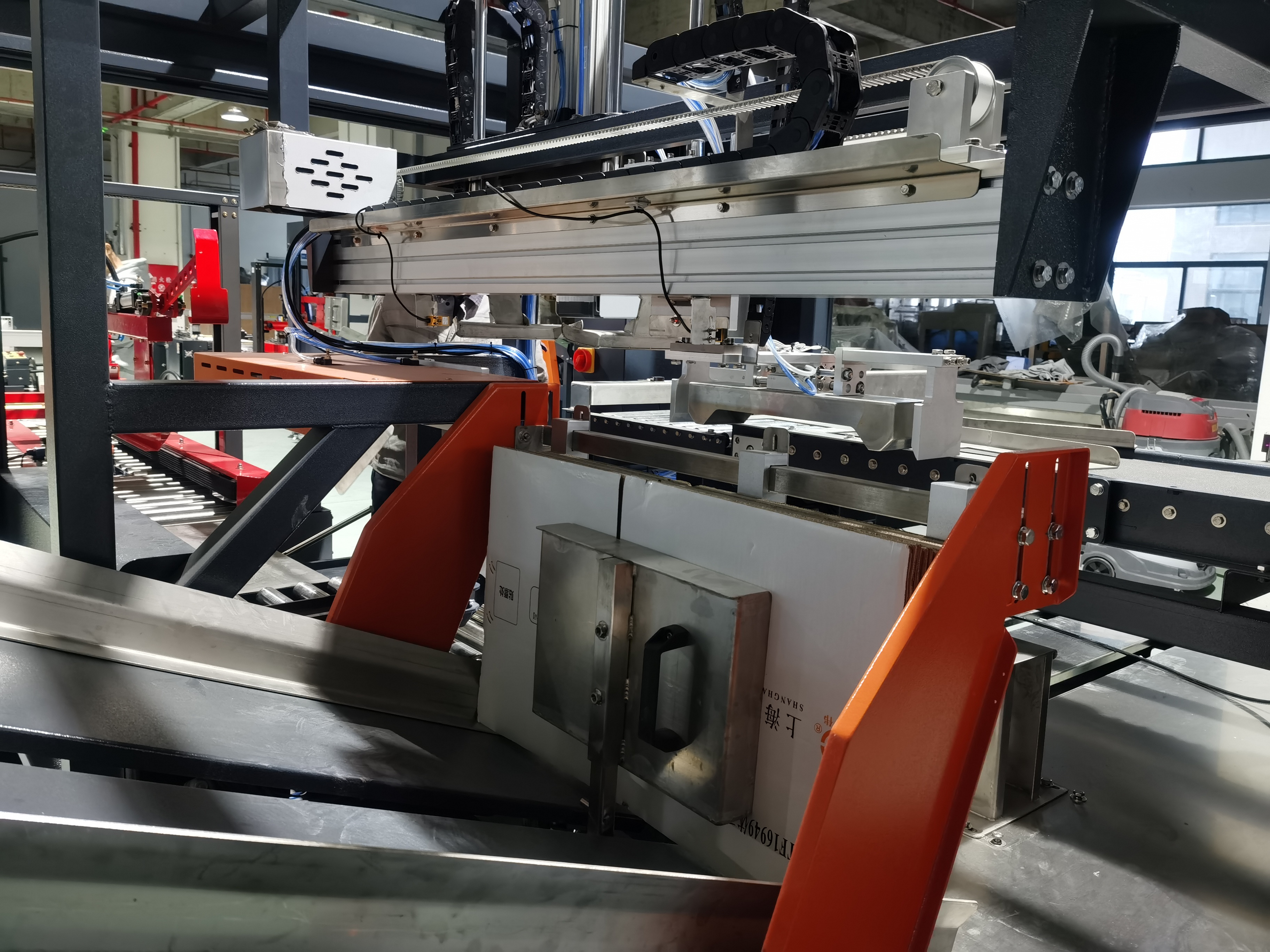

①

Carton forming and filling machine

The first step in a carton packing line is the carton forming and filling machine. This machine automatically open then fills cartons with small boxes, that have been sorted and prepared for packaging. The cartons are then moved along the conveyor to the next step in the process.

②

Tape sealing machine

The second step is the carton sealing machine. This machine automatically seals the filled cartons using pre-made adhesive tape.The sealed cartons are then sent down the conveyor to the next step.

③

Strapping machine

The third step is the carton strapping machine. This machine straps the cartons with cable ties to secure them for transport. Strapping helps to prevent the cartons from being damaged during transit, while also making it easier to handle them during loading and unloading.

④

Labelling machine

Laser coding or

lnstant printing and labeling machine.

According to the template you set in the machine, instant print number, QR code or bar code. Convenient warehouse management.

⑤

Palletizer

The final step in the carton packing line is the palletizing machine. This machine automatically stacks and arranges the

strapped cartons onto pallets for transport. Once the pallets are full, they are wrapped in plastic and labeled for shipment.

strapped cartons onto pallets for transport. Once the pallets are full, they are wrapped in plastic and labeled for shipment.

Advantage:

A carton packing line offers a high level of efficiency and consistency in the packing process. By automating the process of forming, filling, sealing, strapping and palletizing cartons, this type of system can reduce labor costs, increase production rates, and improve the overall quality of the finished product.

Technical Parameters:

|

Model

|

Automatic Carton Packing Line

|

|

Machine Material

|

Carbon steel, 304 stainless steel

|

|

Packing Speed

|

3-10 cartons/minute

|

|

Size of Large Carton

|

Customized according to requirements

|

|

Voltage

|

AC220V, 50Hz, 6KW

|

|

Gas Consumption

|

0.5--0.7 Mpa, 20L/ Min

|

Sample Cartons:

Packaging & Delivery

|

Packaging:

|

Packed in export standard plywood cases.

|

|

Delivery:

|

Usually 30 to 45 days after the order is confirmed.

|

Our Service

· We will provide the best service in the sale.

· Professional engineers can design any special solutions for you.

· We assure all the machines one year to maintain good quality and high efficient performance, and provide life-long maintenance services.

· During the COVID-19, we provide professional English installation, instructions, and online guidance.

· We will ensure high quality to meet your any requirements.

· Professional engineers can design any special solutions for you.

· We assure all the machines one year to maintain good quality and high efficient performance, and provide life-long maintenance services.

· During the COVID-19, we provide professional English installation, instructions, and online guidance.

Follow Us

FAQ

1. For providing exact quote and solution, what’s needed?

(1) What product will the machine pack?

(2) What’s your bag type(pillow bag, gusset bag, quad bag,etc)?

(3) What’s the bag size and film width?

(4)What kind of film material will use, laminated film or PE film?

(2) What’s your bag type(pillow bag, gusset bag, quad bag,etc)?

(3) What’s the bag size and film width?

(4)What kind of film material will use, laminated film or PE film?

2. What's the delivery time?

For standard machine, it takes about 25-35 days for production, and for customized projects need to be negotiated.

3. What about the installation and commission?

We will provide manual and video to show you how to install the machine. If needed, we can also ask our

engineer to buyer’s factory to install the machine and train the workers there. But the buyer should pay for the round-ticket,

visa charge, food and accommodation.

engineer to buyer’s factory to install the machine and train the workers there. But the buyer should pay for the round-ticket,

visa charge, food and accommodation.

4. What about after-sales service?

The machine have one year warranty and lifelong technical support. We will offer the broken spare parts for free within Warranty period.

Hot Searches