- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

GRISH

-

Model Number:

-

PCD

-

Use:

-

Grinding and Polishing, Grinding and lapping

-

Product name:

-

Detonation Polycrystalline Diamond Powder

-

Application:

-

Sapphire/SiC wafer/ Metal/Ceramic

-

Advantage:

-

factory wholesale

Quick Details

-

Type:

-

abrasive

-

Abrasive Grain Sizes:

-

10-1/0-2/2-4/4-8

-

Warranty:

-

1 Year

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

GRISH

-

Model Number:

-

PCD

-

Use:

-

Grinding and Polishing, Grinding and lapping

-

Product name:

-

Detonation Polycrystalline Diamond Powder

-

Application:

-

Sapphire/SiC wafer/ Metal/Ceramic

-

Advantage:

-

factory wholesale

Product Name:Detonation Polycrystalline Diamond Powder

Key World:

diamond dust powder

olycrystalline diamond powder

diamond powder thermal resistance

Packing:

Plastic Bottle/Bag

Products Description

|

Name

|

Detonation Polycrystalline Diamond Powder

|

|

Features

|

High wear resistance and long service life

|

|

Materials

|

Diamond

|

|

Sample

|

Sample Provided

|

|

Packing

|

Packing

|

|

Grit Size

|

30/9/3/1/0.5 micron,etc

|

|

Advantage

|

factory wholesale

|

|

Place of Origin

|

Beijing China

|

|

Usage

|

Grinding and lapping

|

|

Capacity

|

Large

|

|

Logistics information

|

customers' requirements

|

Product Description:

GRISH detonation polycrystalline diamond powder (PCD) is produced in a controlled explosion. Grains microscopic structure is similar with natural Carbonado.

Compared with monocrystalline diamond, PCD has more cutting edges, resulting in the higher removal rate, with good self-sharpening proprieties. The structure will always open new sharp edges introduced by releasing an outer layer of dull crystallites. The polycrystalline diamond can give higher removal rate and lowest level of scratches. That’s why it is especially suitable for the high precision processing on super hard material.

Features:

1.Higher toughness and better self-sharpening properties compared with monocrystalline diamond.

2. Higher removal rate, less scratches, more consistent polishing performance compared with monocrystalline diamond.

3.Long life and highyield.

4.High wear resistance and long service life.

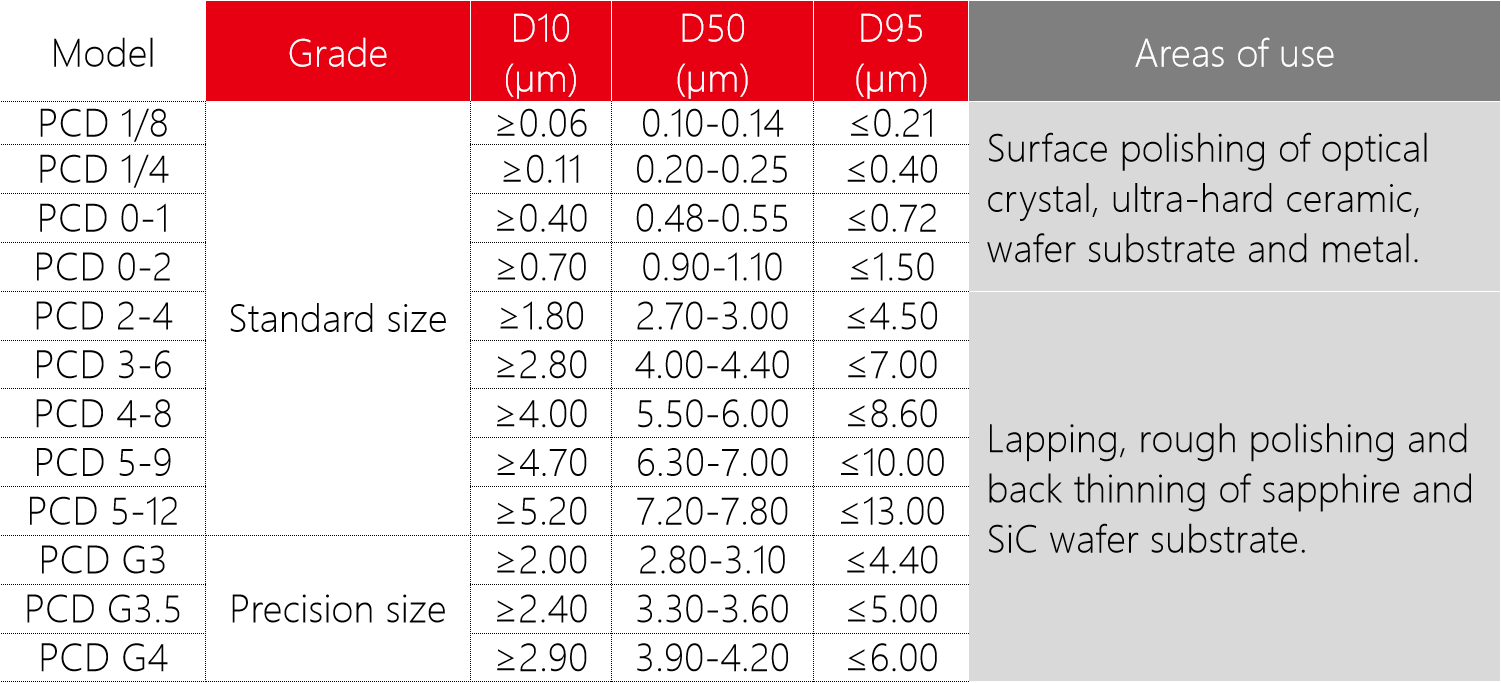

Specification

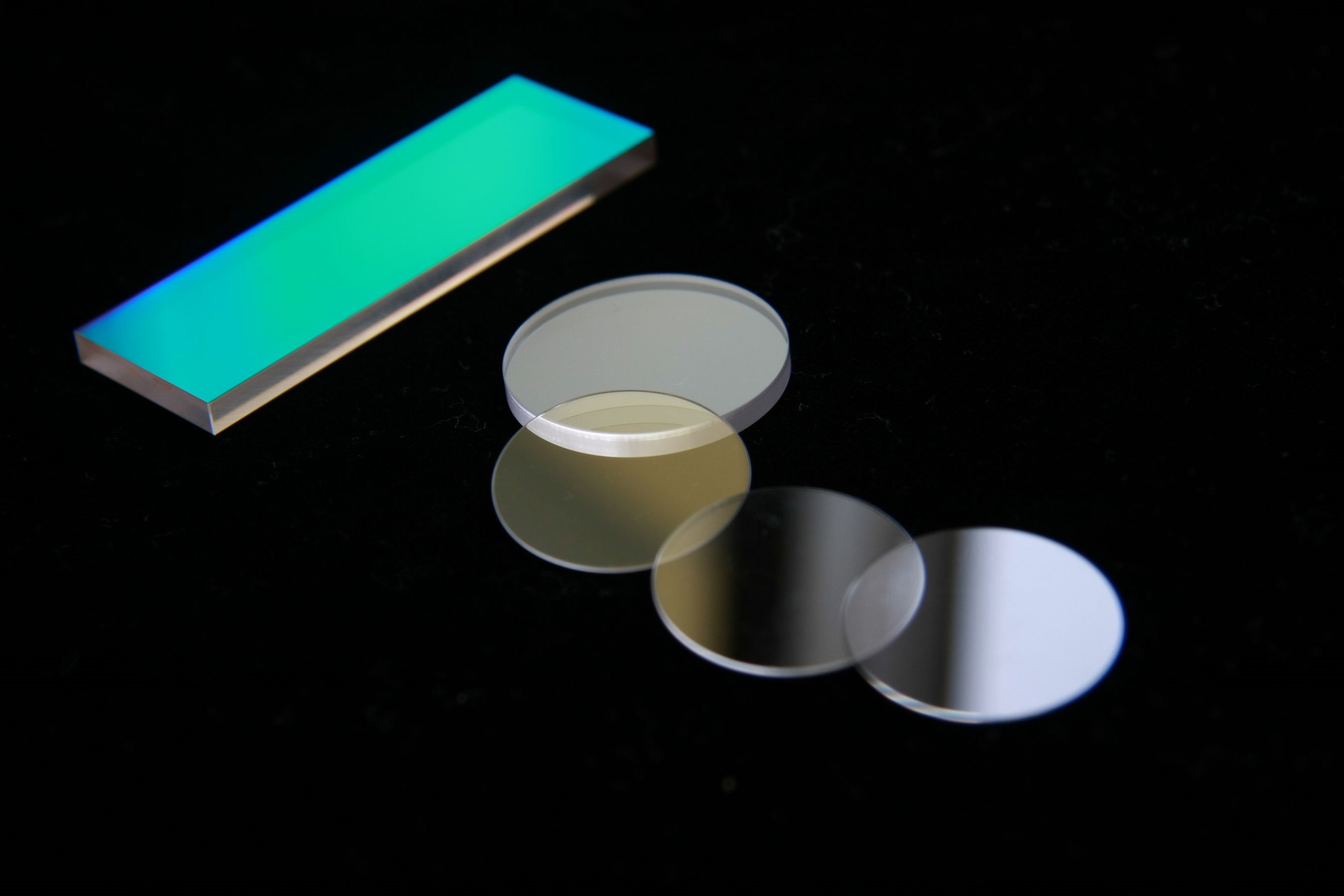

Application

Sapphire and SiC wafer

Optical glass and crystal

Ceramic and metal

Application

FAQ

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Q1: Are you trading company or manufacturer ?

A: We are manufacturer.

Q2:What will be the delivery cost?

A:All price listed are FOB Beijing. Your nominated courier is acceptable. Otherwise, we will use FEDEX, DHL, UPS or any other forwarder per confirmation and charge accordingly

Q3:Can I have our own logo on the products?

A: That's ok to have your own logo on the products.(OEM\ODM) Please contact with us to make sure the detailed things before placing order.

Q4:How about your delivery date?

A: Delivery date is about 3-5days, it depends on the order quantity

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches