- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E0

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KANGTAO

-

Product name:

-

Film Faced Plywood

-

Material:

-

MR/E0/E1/E2/WBP/Melamine

-

Face/back:

-

Melamine Paper

-

Thickness:

-

8-18mm

-

MOQ:

-

500

-

Core:

-

Acacia

-

Glue:

-

MR/E0/E1/E2/WBP/Melamine

-

Size:

-

2440mm*1220mm, 1830mm*915mm

-

Certification:

-

ISO9001

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Construction, Building Construction

-

Formaldehyde Emission Standards:

-

E0

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KANGTAO

-

Product name:

-

Film Faced Plywood

-

Material:

-

MR/E0/E1/E2/WBP/Melamine

-

Face/back:

-

Melamine Paper

-

Thickness:

-

8-18mm

-

MOQ:

-

500

-

Core:

-

Acacia

-

Glue:

-

MR/E0/E1/E2/WBP/Melamine

-

Size:

-

2440mm*1220mm, 1830mm*915mm

-

Certification:

-

ISO9001

Product Description

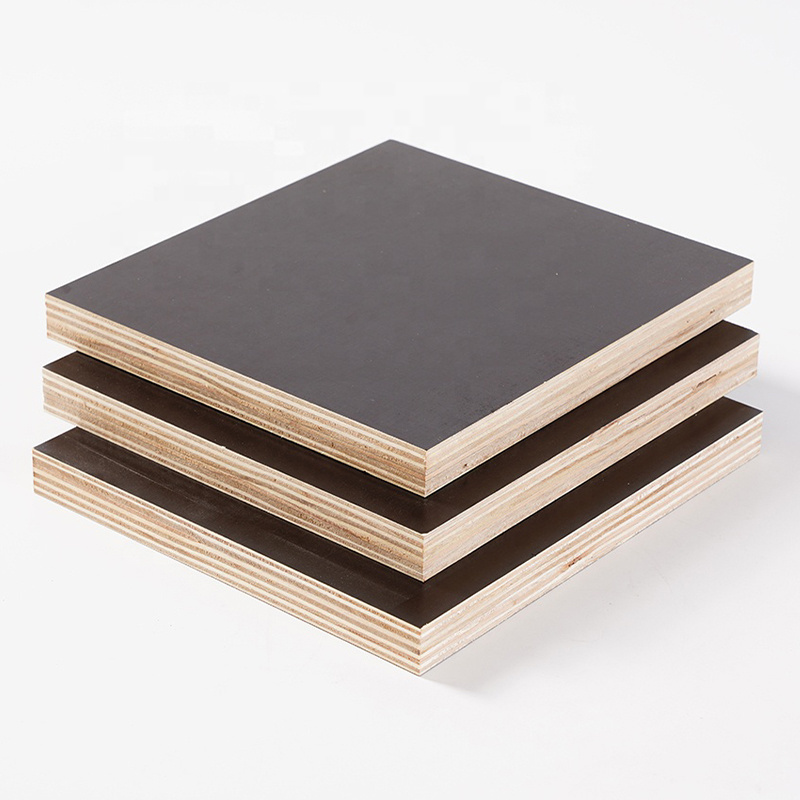

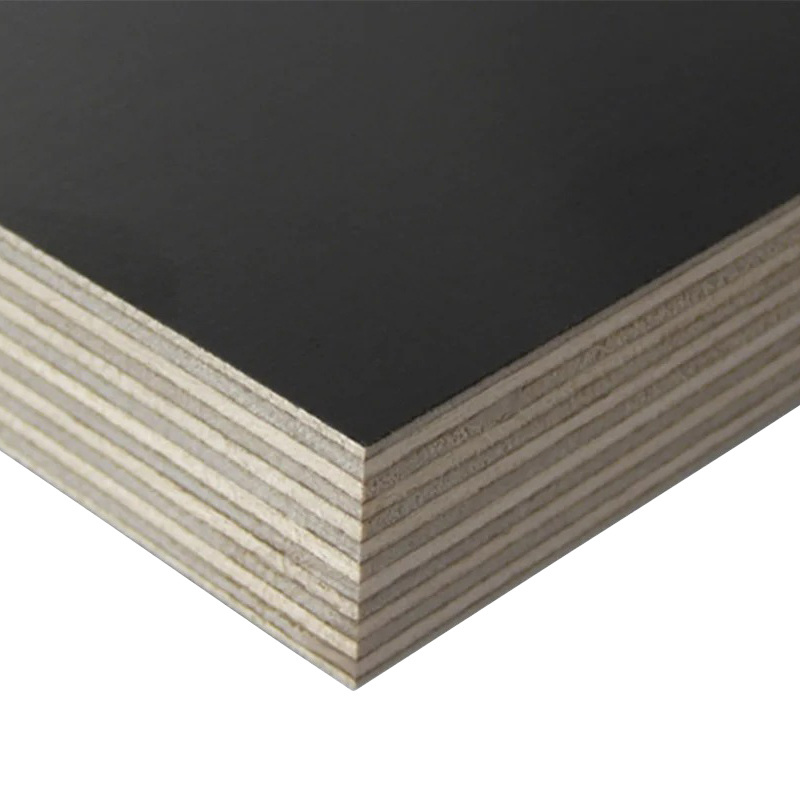

Film Faced Plywood

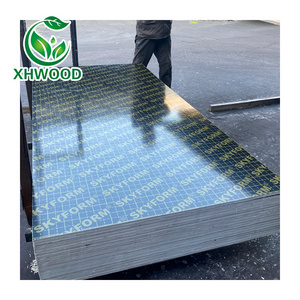

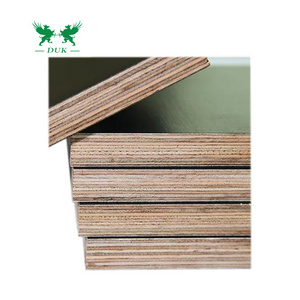

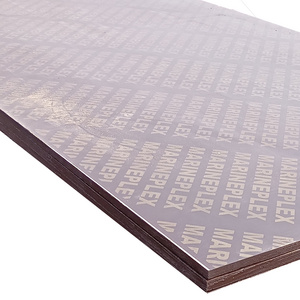

Film faced plywood is well-known as formwork plywood, especially engineered for the concrete formwork. This plywood is based on Exterior WBP (Water Boiled Proof) glue plywood. Using very special lamination line and presses phenolic film is glued on both sides of plywood. Film Faced plywood is extremely durable in severe conditions such as concrete forming,flooring, trucks parts,etc.

Film Faced Plywood as One of the most popular building material for concrete construction .it is a reusable panel with waterproof film on both sides ,can dimension of the wall , because of different wood species&quality inside the plywood ,the reusable time from 10-60 times , but the weight around 30kg which is much less than the iron and steel which in same dimension .

Low carbon environmental protection, bending, compression, wear resistance, falling, moisture resistance and wear resistance,Easy to use: the surface of the pouring object is smooth and beautiful, minus the secondary plastering process of the wall, which can directly decorate the surface and shorten the construction period.

Film Faced Plywood as One of the most popular building material for concrete construction .it is a reusable panel with waterproof film on both sides ,can dimension of the wall , because of different wood species&quality inside the plywood ,the reusable time from 10-60 times , but the weight around 30kg which is much less than the iron and steel which in same dimension .

Low carbon environmental protection, bending, compression, wear resistance, falling, moisture resistance and wear resistance,Easy to use: the surface of the pouring object is smooth and beautiful, minus the secondary plastering process of the wall, which can directly decorate the surface and shorten the construction period.

Specification

|

Size

|

1220*2440mm,1200*2400mm,1250*2500mm,900*2100,etc

|

|

Thickness

|

9,12,15,16,17,18,20,21,25,27,30mm

7/16inch(9-9.5mm) ,1/2inch(12-12.7mm)

5/8inch(15-16mm) ,3/4inch(18-19mm) |

|

Face&Back

|

Dynea Film (Black ,brown Red ,yellow ,Dark brown), Anti Slip film ,plastic film

|

|

Grade

|

One Time Hot press / Two Time hot press / Finger-Joint

|

|

Tolerance

|

+/-0.5mm

|

|

MOR/MOE

|

MOR ≥30Mpa;MOE ≥6000Mpa

|

|

Density

|

Poplar: 530~500kgs/cbm, hardwood:600~580kgs/cbm

|

|

Usage

|

Ideal concrete construction materials ,concrete forming, flooring, trucks parts

|

|

MOQ

|

20GP Container

|

|

Loading Quantity

|

20’ GP-8pallets/22CBM 40’ HQ-18pallets/50CBM or upon request

|

|

Delivery Time

|

Usually within 10-15 days after receipt of advance payment

|

Hot Searches