High precision machine bed

1. Fiber laser cutting machine lathe bed part completely independent research and development, by the party welding lathe bed

base, through the large gantry milling machine. 2. For large machine bed we have many years of experience in processing, each

machine bed will be placed 30 to 45 days after rough machining natural failure, the internal stress release completely again after

finishing, ensure the machining accuracy. High strength, stability, ensuring 20 years of use without distortion.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

WEIHONG

-

Cutting Area:

-

3050*1550mm

-

Cutting Thickness:

-

12mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Raytu

-

Weight (KG):

-

4500 KG

-

Warranty of core components:

-

3 Year

-

Key words:

-

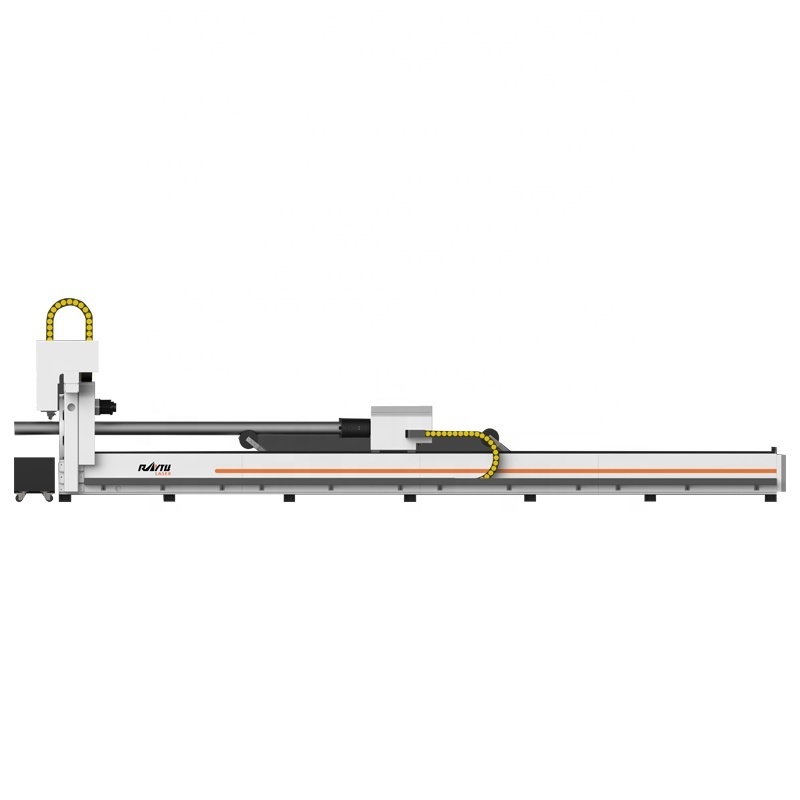

China Cnc Laser Pipe Cutter Machine

-

Product name:

-

Fiber laser pipe/tube cutting machine

-

Model:

-

RT6024M

-

Cutting materials:

-

Metal tube pipe

-

Fiber Laser Source:

-

1500W 2000W 3000W

-

Certification:

-

ISO CE

-

After-sales Service Provided:

-

3 Years

-

Working Voltage:

-

380V 3 PHASE 50hz/60hz

-

Positioning Accuracy:

-

0.03mm

-

Laser head:

-

Raytools/WSX

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

80m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

WEIHONG

-

Cutting Area:

-

3050*1550mm

-

Cutting Thickness:

-

12mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Raytu

-

Weight (KG):

-

4500 KG

-

Warranty of core components:

-

3 Year

-

Key words:

-

China Cnc Laser Pipe Cutter Machine

-

Product name:

-

Fiber laser pipe/tube cutting machine

-

Model:

-

RT6024M

-

Cutting materials:

-

Metal tube pipe

-

Fiber Laser Source:

-

1500W 2000W 3000W

-

Certification:

-

ISO CE

-

After-sales Service Provided:

-

3 Years

-

Working Voltage:

-

380V 3 PHASE 50hz/60hz

-

Positioning Accuracy:

-

0.03mm

-

Laser head:

-

Raytools/WSX

Product Description

Product Paramenters

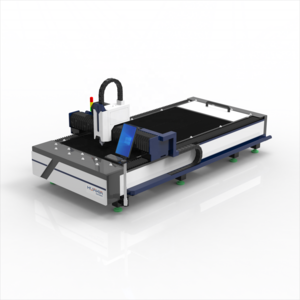

|

Equipment Specification

|

|

|

|

|

|

|||||

|

Model

|

RT3015H

|

RT4015H

|

RT6015H

|

RT4020H

|

RT6020H

|

|||||

|

Cutting area

|

3000*1500mm

|

4000*1500mm

|

6000*1500mm

|

4000*2000mm

|

6000*2000mm

|

|||||

|

Laser source

|

MAX

|

MAX

|

MAX

|

MAX

|

MAX

|

|||||

|

MAX moving speed

|

100m/min,ACC=1.0G

|

100m/min,ACC=1.0G

|

100m/min,ACC=1.0G

|

100m/min,ACC=1.0G

|

100m/min,ACC=1.0G

|

|||||

|

Position accuracy

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

|||||

|

Reposition accuracy

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

|||||

|

Power

|

380V 50/60HZ 50A

|

380V 50/60HZ 50A

|

380V 50/60HZ 50A

|

380V 50/60HZ 50A

|

380V 50/60HZ 50A

|

|||||

|

MAX loading

|

≤4000

|

≤5000

|

≤5500

|

≤6000

|

≤6000

|

|||||

Lathe bed

Laser source

Control system

Water Chiller

Servo motor

Laser head

Lathe bed

Laser Head

1. Optimized design structure: modularization, easy maintenance, and reduced downtime.

2. Multiple protective lenses: 3 protective lenses, efficient protection of collimating focusing lenses.

3. Durable and durable: 2-way optical water cooling, effectively extending continuous working time.

4. Closed-loop step-by-step automatic focusing: A closed-loop stepper motor is used to effectively avoid losing steps. The

focusing speed is 100mm/s, and the repeatability is 1μm.

5. Fast piercing High speed cutting: 16mm low carbon steel, piercing time <6 seconds, cutting speed 0.6m/min.

2. Multiple protective lenses: 3 protective lenses, efficient protection of collimating focusing lenses.

3. Durable and durable: 2-way optical water cooling, effectively extending continuous working time.

4. Closed-loop step-by-step automatic focusing: A closed-loop stepper motor is used to effectively avoid losing steps. The

focusing speed is 100mm/s, and the repeatability is 1μm.

5. Fast piercing High speed cutting: 16mm low carbon steel, piercing time <6 seconds, cutting speed 0.6m/min.

Water chiller

1. Automatically adjust the temperature according to different working environment, no need to change settings parameters. Reduce

the temperature of the laser source and the laser head through water circulation, thereby protecting these two main parts.

2. The chiller has functions such as water flow protection and water temperature protection. If the chiller is not opened or the

water flow is insufficient, the laser will not be generated when the water temperature is too high, so as to protect the laser.

the temperature of the laser source and the laser head through water circulation, thereby protecting these two main parts.

2. The chiller has functions such as water flow protection and water temperature protection. If the chiller is not opened or the

water flow is insufficient, the laser will not be generated when the water temperature is too high, so as to protect the laser.

Servo motor

Y axis: Double sets Japanese FUJI servo motors and drivers.

X axis: Japanese FUJI Servo motor and driver Our X Y axis structure increases machine speed and precision and more stable for

machine working.

Z axis: Japanese Servo motor and driver.

X axis: Japanese FUJI Servo motor and driver Our X Y axis structure increases machine speed and precision and more stable for

machine working.

Z axis: Japanese Servo motor and driver.

Control System

1. Advantech industrial computer, with professional Weihong optical fiber cutting control system, can cut metal plates well. High

cutting speed and perfect cutting edge, smooth plane and exquisite texture. 2. Save the metal cutting parameters of various

technologies in the computer before leaving the factory.

cutting speed and perfect cutting edge, smooth plane and exquisite texture. 2. Save the metal cutting parameters of various

technologies in the computer before leaving the factory.

Packing & Delivery

Package:Standard Export Non-fumigate Wooden Case

Hot Searches