- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

0.2-1tph

-

Usage:

-

Mining Separatoion

-

Material:

-

FRP

-

Price:

-

Competitive

-

Model:

-

Processed Customization

-

Installation:

-

Engineer guide

-

Product name:

-

Lab Shaking Tables

-

Name:

-

Shaker Table Machinery

-

Certification:

-

CE, ISO or other

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service, Overseas service center available

-

Application:

-

Gold, Chromite or other

-

Capacity:

-

0.2-1tph

-

Usage:

-

Mining Separatoion

-

Material:

-

FRP

-

Price:

-

Competitive

-

Model:

-

Processed Customization

-

Installation:

-

Engineer guide

-

Product name:

-

Lab Shaking Tables

-

Name:

-

Shaker Table Machinery

-

Certification:

-

CE, ISO or other

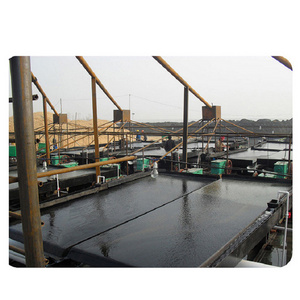

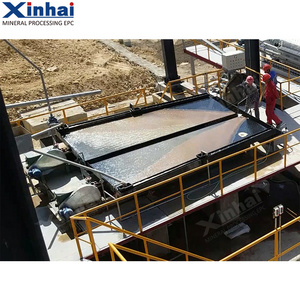

Laboratory Shaking Table Introduction

laboratory shaking table is the main gravity concentrator. It is applicable for the separation of fine-grained, micro-grained rare metal, ferrous and non-ferrous metals, precious metal, coal and other minerals. It can carry out the ore concentration operation independently, also it can work in conjunction with jig, screw separator, centrifugal separator and other equipment.

Laboratory Shaking Table Application

Laboratory shaking table is one of the main equipments of gravity concentration. It is not only widely applied on separating tunium and other rare metals and the noble metal ore.

Laboratory shaking table is also widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc. The shaker effective recycling granularity scope is 2-0.22 millimeters.

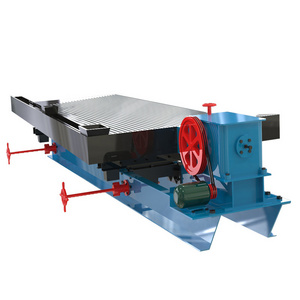

Shaking table working principle

The working principle of Shaking Table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

(1) Feed ore port (9)Horizontal support

(2) Stroke adjusting device (10)Horizontal adjustment wheel

(3) Ore feeding trough (11)Table support

(4) Feed water port (12) Knife-type support

(5) Water feeding through (13)Stand

(6) Table surface (14)Shaking table head

(7) Concentrate side (15) Motor support

(8) Tailings side (16)Swing Adjusting device

| Model and Specification | ||||||

| Table Size(mm) Length×Feed width×Concentrate width | 4520×1850×1560 | 3000×1620×1100 | 2100×1050×850 | 1100×500×430 | ||

| Selective are(m²) | 7.67 | 4.08 | 2 | 0.51 | ||

| Feed size(mm) | coarse sand | 1-2.5 | 0.6-1.5 | 0.4-0.8 | 0.1-0.2 | |

| fine sand | 0.8-1.2 | 0.3-0.8 | 0.2-0.5 | 0.05-0.1 | ||

| slurry | 0.3-0.6 | 0.2-0.4 | 0.1-0.2 | 0.03-0.05 | ||

| Water consumption(t/h) | 0.5~3.5 | 0.3~1.5 | 0.2~1 | 0.1~0.5 | ||

| Stroke(mm) | 8~36 | 10~30 | 12~28 | 9~17 | ||

| Jig frequency(q/m) | 240~380 | 240~420 | 250~450 | 280~460 | ||

| Cross fall(°) | 0°~5° | 0°~8° | 0°~10° | 0°~10° | ||

| Motor | Model | Y70L-4 | Y100L-4 | Y90L-4 | Y80L-4 | |

| Power(kw) | 1.1 | 1.1 | 1.1 | 0.55 | ||

| Revolving speed(r/min) | 1400 | 1400 | 1400 | 1400 | ||

| V-belt(mm) | A-2000 | A-1033 | B-2007 | A-1245 | ||

| Overall Dimension(Length*Width*Height)mm | 5630×1850×900 | 4075×1320×780 | 3040×1050×1020 | 1530×500×800 | ||

| Weight(kg) | 650 | 550 | 350 | 150 | ||

| Notes: The above technical parameters based on stationary type shaking table, are for your reference only. | ||||||