- Product Details

- {{item.text}}

Quick Details

-

Power:

-

110-900

-

Weight (KG):

-

800

-

Name:

-

Wood shaving machine

-

Keywords:

-

Wood shavings

-

COLOR:

-

OEM

-

Blade Quantity:

-

4-8pcs

-

MAX width of wood:

-

500mm

-

Product name:

-

wood shavings machine for sale

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Henan, China

-

Application:

-

Wood shavings

-

Brand Name:

-

ZHANGSHENG

-

Power:

-

110-900

-

Weight (KG):

-

800

-

Name:

-

Wood shaving machine

-

Keywords:

-

Wood shavings

-

COLOR:

-

OEM

-

Blade Quantity:

-

4-8pcs

-

MAX width of wood:

-

500mm

-

Product name:

-

wood shavings machine for sale

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

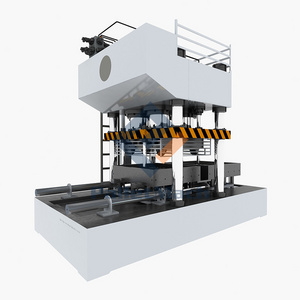

The wood shaving machine is mainly used for mass production of thin shavings with uniform thickness. The finished product is the same as the shavings produced by the wood factory. The wood shaving machine adjusts the size of the finished shavings by adjusting the blade angle and the screen diameter. To adapt to various needs.

The machine can process logs, branches, planks and other woods within 30 cm into wood shavings, divided into multiple models, with an output of 500-2000kg/h. It can meet different needs.

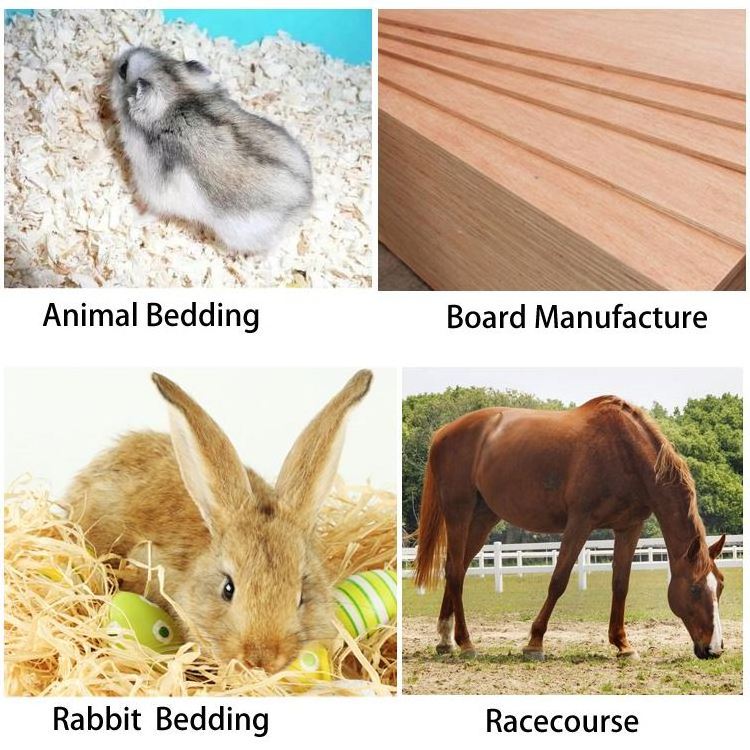

Depending on the number of blades, shavings of different sizes can be cut. Large shavings are suitable for cattle and sheep as gaskets, small shavings are suitable for hamsters, and rabbits are used as cushion nests.

The finished product uses particleboard (plywood), the paper mill is used as the raw material for wood pulp paper, and the transportation company is used as the filler material for the transportation of fragile goods. It is used as filling material for small pigs, cattle, sheep and various animal nests.

High-strength operation

The cutter plate is made of high manganese steel for continuous high-strength operation. The high-manganese steel cutter plate is not easy to deform and has a long life span.

Alloy steel blade

The alloy steel blade has excellent wear resistance and can continuously crush 20 to 30 tons of materials. High-quality blade material can effectively reduce the number of sharpening.

Seamless welding

Each welding process is completed by the most advanced modern seamless welding technology, which makes the machine stronger and more durable.

Outlet duct

A discharge air duct can be installed to directly blow the shavings to the designated position.

|

Model

|

Capacity(t/h)

|

Dimension size (mm)

|

Feeding Port (mm)

|

Motor(kw)

|

Number of Blade

|

|

420

|

0.3-0.5

|

1.3x0.5x0.8

|

130x150

|

7.5/11

|

4

|

|

600

|

0.5-0.8

|

1.4x0.7x0.9

|

180x180

|

15/18.5

|

4

|

|

800

|

1-1.2

|

1.7x1x1.2

|

230x250

|

30/37

|

8

|

|

1000

|

1.5-1.8

|

2x1.3x1.4

|

270x270

|

45/55

|

9

|

|

1500

|

2-2.5

|

2.4x1.6x1.9

|

350x350

|

75/90

|

12

|

Established in 2005, Henan Zhangsheng Environmental ProtectionEquipment Company is headquartered in Zhengzhou City, HenanProvince.,and obtained both lSO and CE certification.The productshave been widely exported to more than 60 countries and get a lot of praise from customers. Our main product is wood recycling equipment. including wood chipper shredders, wood crushers, feed pellet machine,wood pellet machine,horizontal grinder, tub grinder etc.

3 sets of high-power laser cutting machines can meet the material preparation work of 1,000 sets per month.

5 imported CNC lathes, with fast processing speed and high precision of workpieces.

Five dynamic balancing machines ensure that the rotors of each crusher are accurately calibrated. Has an assembly workshop of 5,000 square meters Meet the monthly production task of 1,000 units.

As a professional OEM and exporter of wood chippers, Zhangsheng has exported to more than 45 countries. We have the entire series of Diesel Powered wood drum chippers. From the feeding mode, we have self-feeding wood chipper and hydraulic feeding wood chipper. All wood chippers have CE certification of TUV-SUD and TUV-Rheinland. The total number of wood chippers and

shaving machine

exported to Europe and North America each year is more than 1000 units.

FAQ

Q1:What payment methods do you accept?

We support various payment methods, we can accept 20% or 30% as deposit. If it is a return order, we can receive 100% payment by copy B/L.

We support various payment methods, we can accept 20% or 30% as deposit. If it is a return order, we can receive 100% payment by copy B/L.

Q2:How long is your delivery time?

We have more than 1500 square meters of spot inventory workshop, and it usually takes 5-10 days for goods with sufficient inventory. If you need to customize the equipment, it takes 20-30 days. We will do our best to deliver as soon as possible.

Q3:What if the machine is damaged?

We have more than 1500 square meters of spot inventory workshop, and it usually takes 5-10 days for goods with sufficient inventory. If you need to customize the equipment, it takes 20-30 days. We will do our best to deliver as soon as possible.

Q3:What if the machine is damaged?

One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales service.

Hot Searches