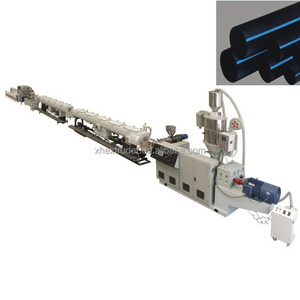

1.2 Special Design of Screw

1.3 Air Cooled Ceramic Heater

1.4 High Quality Gearbox

We also have choice of twin screw and barrel for other material such PP powder, etc.Provide suitable extruder for different customer requirements.