- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

High quality Liquid Nitrogen Blast Freezer Wet Blasting Machine

-

Material:

-

304 Stainless Steel

-

Freezer Type:

-

Nitrogen Freezer

-

Capacity:

-

30-500kg/h

-

Freezing time:

-

10 Minutes

-

Frozen products:

-

Fruit, Vegetable,Seafood,Dumpling

-

Insulation Thickness:

-

160 mm

-

Contact:

-

Bonnie

-

WhatsApp/Viber/Wechat:

-

0086 13838338160

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

1kw

-

Cooling Capacity:

-

100kg/h

-

Place of Origin:

-

Henan, China

-

Product name:

-

High quality Liquid Nitrogen Blast Freezer Wet Blasting Machine

-

Material:

-

304 Stainless Steel

-

Freezer Type:

-

Nitrogen Freezer

-

Capacity:

-

30-500kg/h

-

Freezing time:

-

10 Minutes

-

Frozen products:

-

Fruit, Vegetable,Seafood,Dumpling

-

Insulation Thickness:

-

160 mm

-

Contact:

-

Bonnie

-

WhatsApp/Viber/Wechat:

-

0086 13838338160

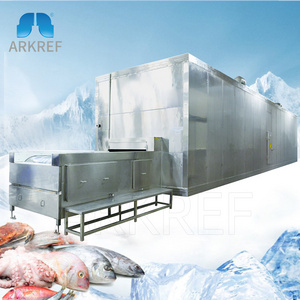

High quality Liquid Nitrogen Blast Freezer Wet Blasting Machine

Description of Liquid Nitrogen Blasting Instant Freezer Machine

This nitrogen quick freezing machine is designed for quick freezing for Baozi, Mantou, sea food, fruits Vegetable etc, it is widely used in many industries.

The time and tempreature can be setting according to your needs, from +120℃ to -196℃ , and after work finished, the alart will let you know.

In a short time which caninhibit the growth of bacteria and keep the food’s original organization structure so as to maintain the fresh taste.

|

Model |

Voltage |

Power |

Weight |

Dimension |

|

AF-NF100 |

220v/380v |

1kw |

300kg |

1300*1212*1700mm |

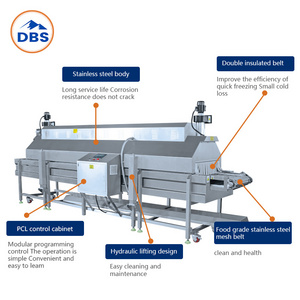

Feature of Liquid Nitrogen Blasting Instant Freezer Machine

Nitrogen Instant freezer is an energy-saving quick freezing machine which is featured by compact structure, wide application, small footprint and large capacity. It is a preferred freezer for food processing companies to freeze meat and other large, thick, and high-temperature products.

Working Principle of Liquid Nitrogen Blasting Instant Freezer Machine

How it works: The quick-freezing machine is mainly composed of refrigeration system, propulsion system, electric control system and quick-freezing room. The staff will carry the frozen plate of frozen food into the quick-frozen track through the quick-frozen entrance and export to the export Direction of the move, in the process of moving, through a fan under the action of the formation of a stable vertical ring low temperature airflow, the low temperature air flow and horizontal movement of frozen food for heat exchange, in order to achieve rapid cooling process.