- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer

-

Dimension(L*W*H):

-

4200*800*1000mm

-

Weight:

-

2500 kg

-

Feeding width:

-

1200mm or Based on design drawing

-

Product name:

-

Omega roll forming machine

-

Color:

-

Customized

-

Control System:

-

PLC with touch screen

-

Thickness:

-

0.3--1mm

-

Feeding Material:

-

Color steel coils

-

Cutting system:

-

Hydraulic Automatic Cutter

-

Roll material:

-

45# high grade steel

-

Shaft material:

-

45# high grade steel

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Feature:

-

High speed, low energy consumption

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20-25 m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer

-

Dimension(L*W*H):

-

4200*800*1000mm

-

Weight:

-

2500 kg

-

Feeding width:

-

1200mm or Based on design drawing

-

Product name:

-

Omega roll forming machine

-

Color:

-

Customized

-

Control System:

-

PLC with touch screen

-

Thickness:

-

0.3--1mm

-

Feeding Material:

-

Color steel coils

-

Cutting system:

-

Hydraulic Automatic Cutter

-

Roll material:

-

45# high grade steel

-

Shaft material:

-

45# high grade steel

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Feature:

-

High speed, low energy consumption

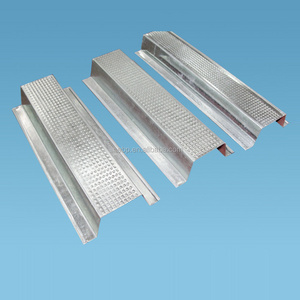

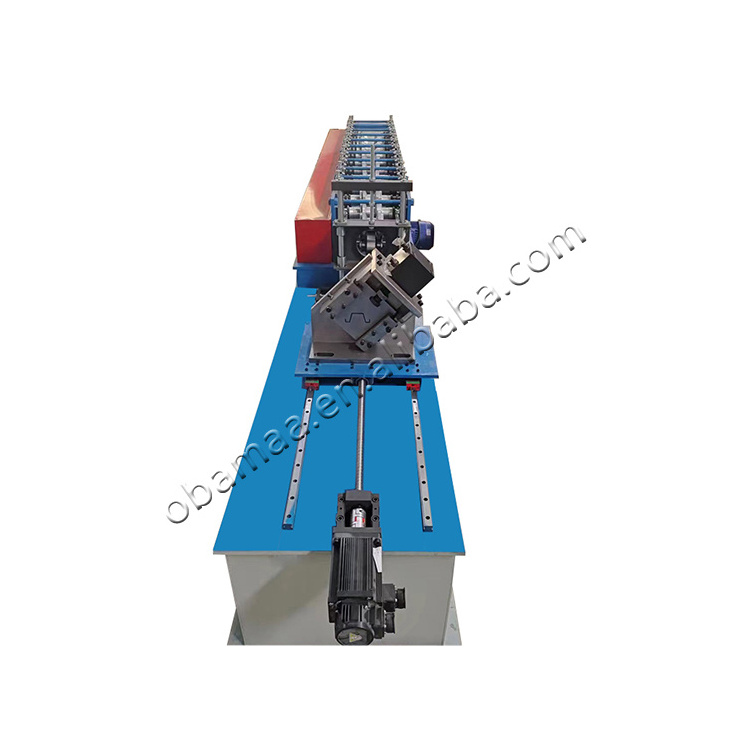

Products Description

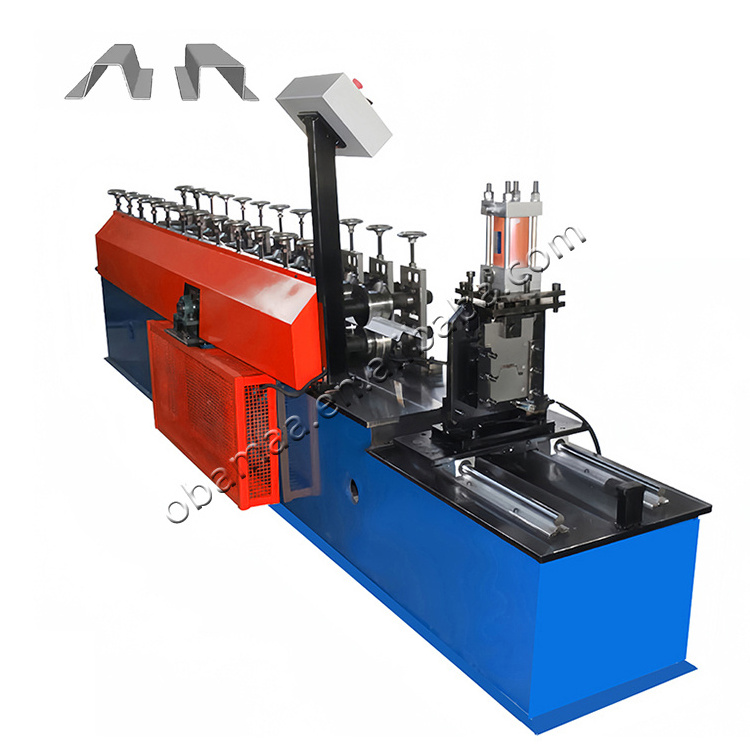

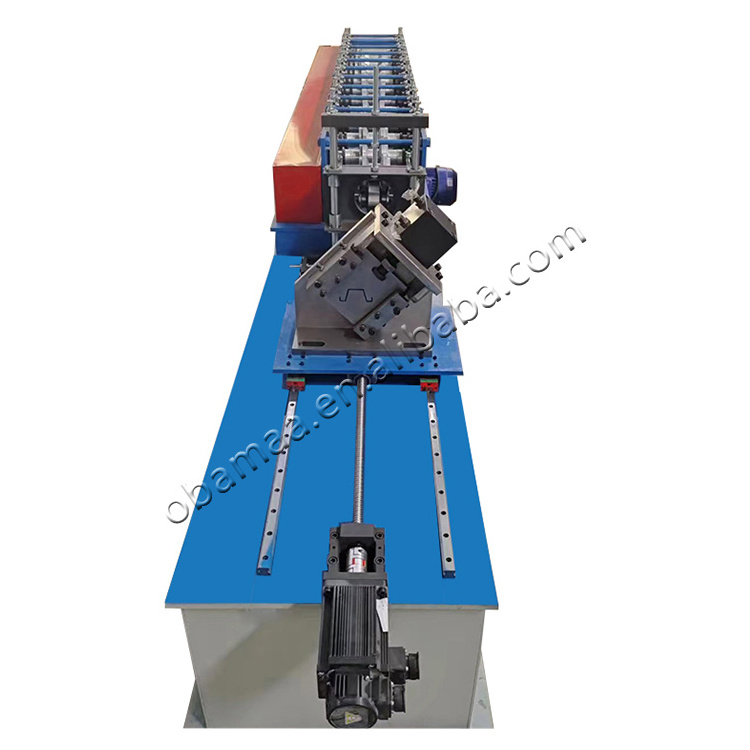

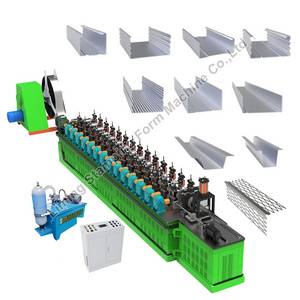

Omega channel profiles keel roll forming machine

The fully automatic Omega type purlin forming machine is a set of rollers used to produce various specifications of Omega purlin forming machines for single finished products. It consists of a passive loading frame, leveling device, punching device, post forming cutting device, hydraulic station, and computer control system. This machine adopts automatic flying saw punching, which is easy to operate. The Omega shaped purlins processed by this machine have

good pressure performance, good flatness, automatic length cutting, automatic punching, high degree of automation, and fast and convenient installation.

Work processing

Specification

|

Omega channel profiles keel roll forming machine

|

|

|

|

|||

|

SN

|

Part details

|

Item Name

|

Specification

|

|||

|

1

|

Material

|

Raw material

|

Steel

|

|||

|

|

|

Thickness

|

0.3-1 mm

|

|||

|

2

|

Machine

|

Roller station

|

12- 20

|

|||

|

|

|

Shaft diameter

|

55 mm

|

|||

|

|

|

Shaft material

|

45# steel with 0.05mm chrome

|

|||

|

|

|

Roller material hardness 30-40 HRC

|

Cr 12

|

|||

|

|

|

Machine size

|

4200*800*1000mm

|

|||

|

|

|

Machine weight

|

About 2.5 ton

|

|||

|

|

|

Machine color

|

As customer' request

|

|||

|

|

|

Working speed

|

20-25 m/min

|

|||

|

3

|

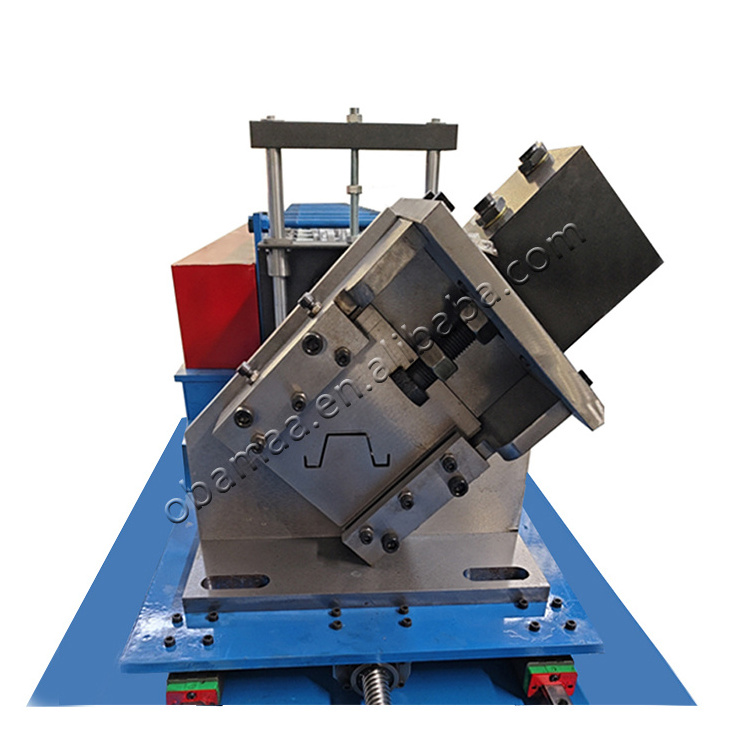

Cutter

|

Operate

|

Hydraulic cutting

|

|||

|

|

|

Material

|

Cr 12

|

|||

|

|

|

Hardness

|

50-65 HRC

|

|||

|

|

|

Cutting tolerance

|

± 1 mm

|

|||

|

4

|

Power

|

Main power

|

4 kw

|

|||

|

|

|

Pump power

|

3 kw

|

|||

|

|

|

Driving way

|

Chain 1 inch

|

|||

|

|

|

Voltage

|

Customize as customer' request

|

|||

|

5

|

Control system

|

Language

|

English or add language as customer need

|

|||

|

|

|

PLC brand

|

Delta or customize as customer' request

|

|||

|

|

|

Screen

|

Touchable screen

|

|||

|

6

|

Decoiler

|

Operation

|

Manual

|

|||

|

|

|

Weight capicatity

|

3 tons or 5 tons

|

|||

|

|

|

Price

|

Free as gift

|

|||

|

7

|

Receiving table

|

Operation

|

Manual

|

|||

|

|

|

Length

|

3 m

|

|||

|

|

|

Price

|

Free as gift

|

|||

Product Details

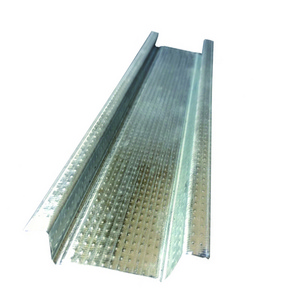

Sample Room

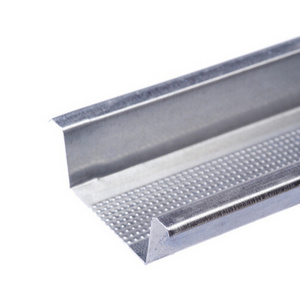

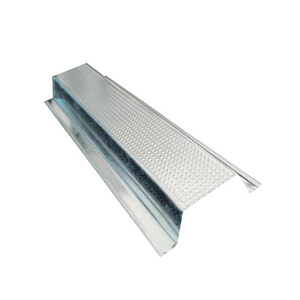

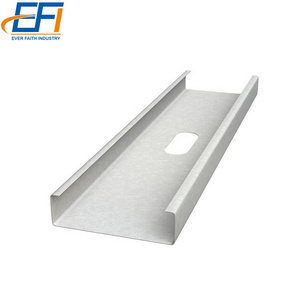

Finished product effect for your reference.

The following are the products produced by our machine. Please check the rolling forming effect.

Other Product

Packing&Delivery

Hot Searches