- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ORINNO

-

Dimension(L*W*H):

-

150*120*100CM

-

Weight (KG):

-

1000

-

Size:

-

150*120*100CM

-

Application:

-

busbar cutting,hole punching,bending

-

Feature:

-

PLC NC control

-

Certification:

-

ISO,CE,UL

Quick Details

-

Max. Thickness (mm):

-

10 mm

-

Max. Width (mm):

-

10 mm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ORINNO

-

Dimension(L*W*H):

-

150*120*100CM

-

Weight (KG):

-

1000

-

Size:

-

150*120*100CM

-

Application:

-

busbar cutting,hole punching,bending

-

Feature:

-

PLC NC control

-

Certification:

-

ISO,CE,UL

Products Description

|

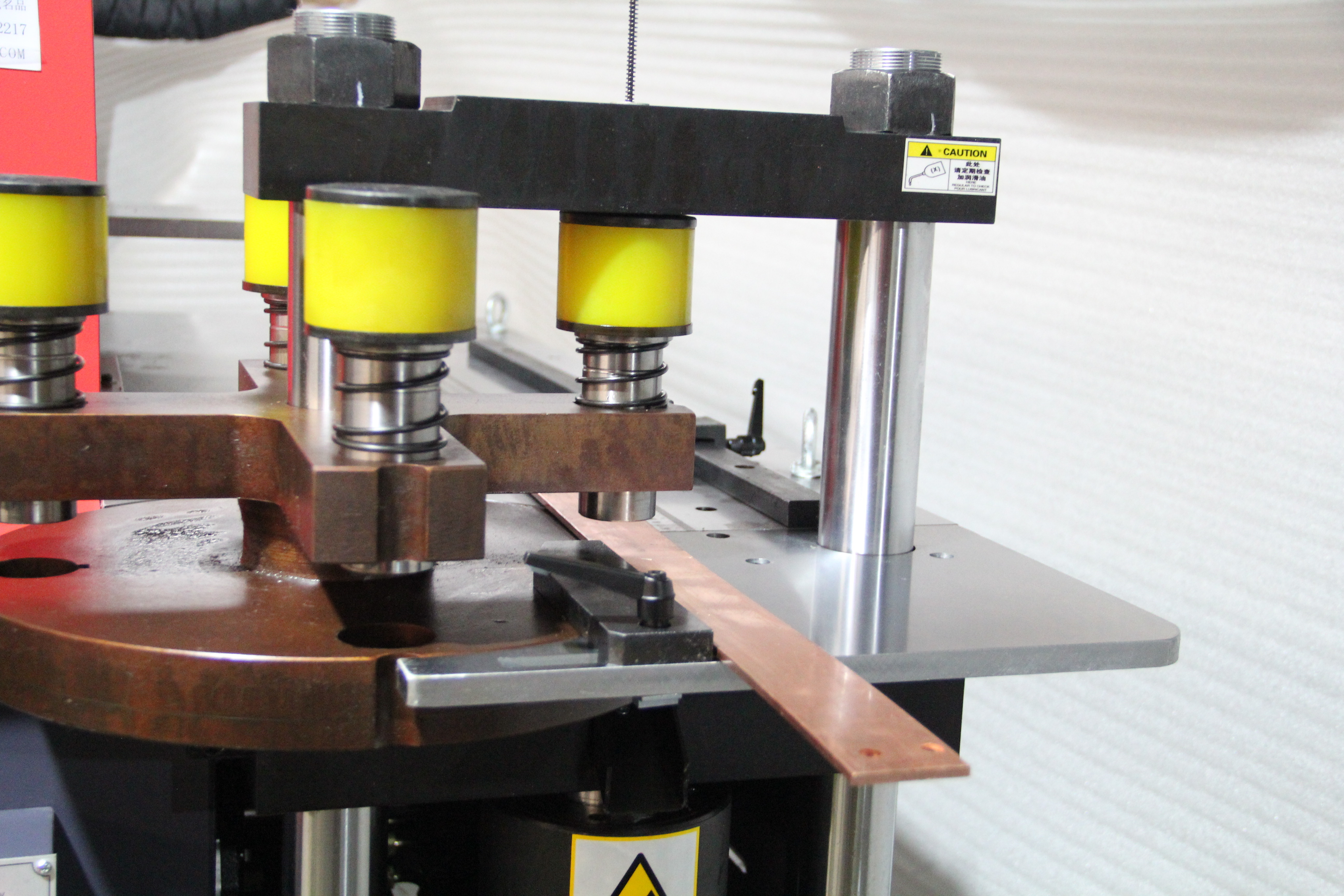

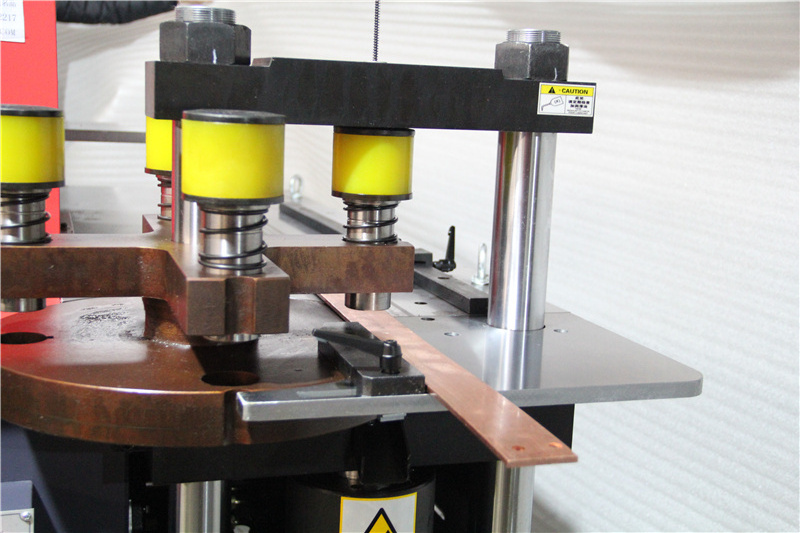

For punching:

|

Max. punching pressure: 300kN

Hole diameter: 4.3-25mm Max. thickness: 12mm Max. width: 150mm Punching dies: six sets mounted on the machine (from 4.3~25mm) |

|

For cutting:

|

Max. cutting thickness: 12mm

Max. cutting width:160mm |

|

For bending:

|

Max. bending pressure: 300KN

Max. bending width:160mm Max. bending thickness: 12mm Equipped with two bending tools: R5 and R10 For vertical bending: Max. bending width: 120mm (12mm thickness copper) Min. bending angle: 90° |

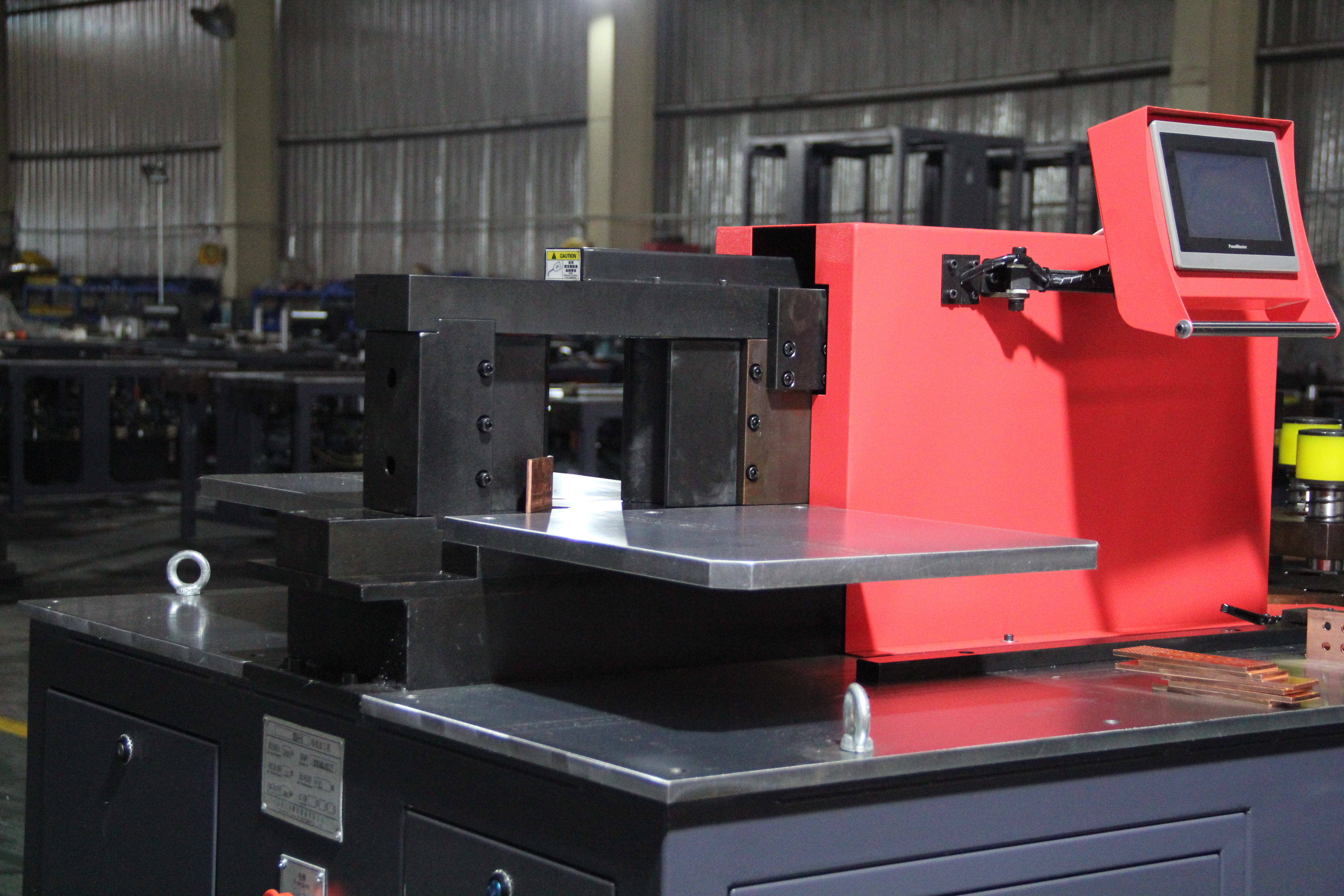

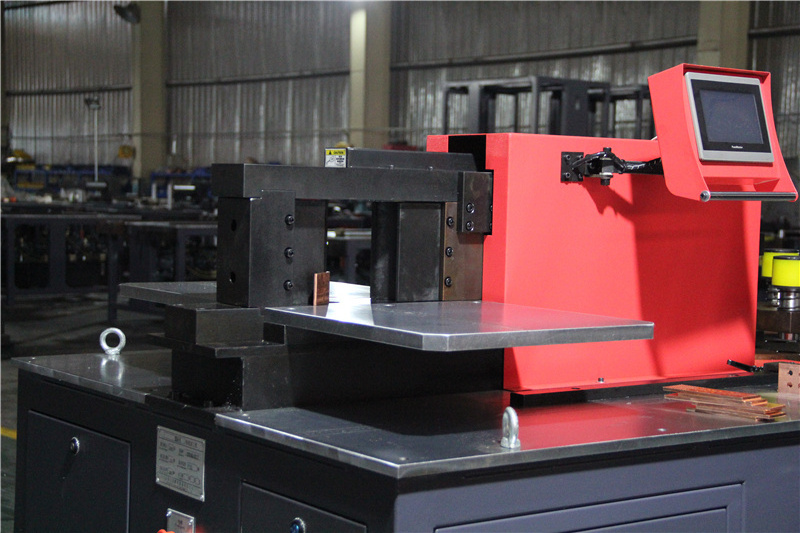

Machine Composition

1 Main driving motors

2 Hydraulic station

3 Electromagnetic valves and overflow valves

4. Touch screen

5 PLC and electrical cabinet

Main Feature

1.PLC control, more stable and reliable than traditional relay control, and can control the downwards time of shearing and punching, but also has automatic shutdown function

2.The shearing unit is common double-blade type cutting, cutting edge is smooth without burr

3.The dies mounting holes are proceeded by the CNC machining center, high precision. The bending angle can be NC control with save memory function, extremely convenient

4.The machine adopts the one-on-one hydraulic supply, three oil cylinders, three oil pumps, no influence with each other.

5.the machine equips with wheels for easy moving, you can easily move.

Application

This machine is special for processing aluminum and copper busbars used in electric power, high/low voltage electric apparatus and busway industries. It combines punching, cutting and bending units, and three units can work simultaneously.

Recommend Products

Hot Searches