- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

9009-54-5

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Fleixbond

-

Model Number:

-

8101

-

Type:

-

paste type, Paste type

-

Product name:

-

polyurethane sealant

-

advantage:

-

environment friendly

-

Application:

-

Auto parts bonding

-

Color:

-

Black White

-

Shelf life:

-

12month

-

Function:

-

composite materials bonding

-

Packing:

-

12pcs per box

-

Brand:

-

Flexibond

-

Certificate:

-

ISO

Quick Details

-

CAS No.:

-

471-34-1

-

Other Names:

-

pu glue

-

MF:

-

C10H8N2O2C6H14O3

-

EINECS No.:

-

9009-54-5

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Fleixbond

-

Model Number:

-

8101

-

Type:

-

paste type, Paste type

-

Product name:

-

polyurethane sealant

-

advantage:

-

environment friendly

-

Application:

-

Auto parts bonding

-

Color:

-

Black White

-

Shelf life:

-

12month

-

Function:

-

composite materials bonding

-

Packing:

-

12pcs per box

-

Brand:

-

Flexibond

-

Certificate:

-

ISO

Description

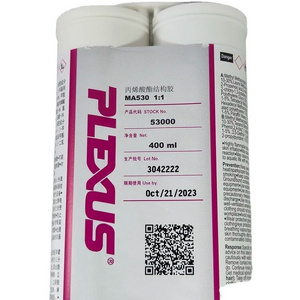

Flexibond 8101 is a two-component structural polyurethane sealant, which is mainly used for auto body adhesive of composite materials parts, such as SMC, BMC, RTM, FRP etc. and adhesion of metal materials. It is environmental friendly, contains no volatile solvents.

Technical Data Sheet

|

|

Component A(Resin)

|

Component B(Hardener)

|

|

|

Cure mechanism

|

Addition reaction

|

|

|

|

Foundations of chemistry

|

Polyhydroxy compond

|

Polyisocyanates

|

|

|

State

|

Black uniform paste

|

Light yellow uniform paste

|

|

|

The state after mixing

|

Black uniform paste

|

|

|

|

Density (before curing)

|

1.25g/cm3

|

1.65g/cm3

|

|

|

Mixing proportion (weight)

|

1

|

1

|

|

|

Initial cure time (23℃)

|

20-40 min

|

|

|

|

Application time (23℃)

|

5-15 min

|

|

|

|

Temperature for application

|

0-30 ºC

|

|

|

|

Movable and bearing time (23℃)

|

1-1.5h

|

|

|

|

Hardness shore D(GB/T 531-2008)

|

≧65

|

|

|

|

Shear strength (GB/T 7124-2008)

|

≥13Mpa (Aluminum alloy)

|

|

|

|

Shelf life

|

12 months

|

6 months

|

|

Advantages

(1) Good thixotropy, no sagging

(2) Cures fast under room temperature

(3) Excellent adhesion to substrates, high boding strength and impart resistance

(4) Excellent water, corrosion and weather resistance

(2) Cures fast under room temperature

(3) Excellent adhesion to substrates, high boding strength and impart resistance

(4) Excellent water, corrosion and weather resistance

Application

Flexibond 8101

is mainly tier 1 used for auto body adhesive of composite materials parts, such as SMC, BMC, RTM, FRP etc. and adhesion of metal

materials. It is environmental friendly, contains no volatile solvents.

It can be used for various kind of vehicles, such as the Car door panel, Tailgate, Spoiler, Truck roof Cap, etc, various composite materials bonding

Hot Searches