The bottle blowing device of HM-S3L2C is controlled by a PLC control system. The entire process is completed with one touch of a

key, with a control accuracy of 0.01 seconds.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

20000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HENGMEI

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

Dimension(L*W*H):

-

2350*740*1880mm

-

Hollow part volume:

-

20L

-

Clamping Force (kN):

-

80

-

Power (kW):

-

25

-

Weight (KG):

-

1500 KG

-

Keywords:

-

Semi-Automatic Bottle Blowing Molding Machine

-

Suitable bottle:

-

5Gallon 20L PET Bottle

-

Bottle material:

-

PET Material

-

Cavity:

-

1-cavity

-

Maximum template area:

-

430*650mm

-

Max mold thickness:

-

410mm

-

Min mold thickness:

-

250mm

-

Clamping force:

-

80KN

-

Power:

-

25kw

-

Product name:

-

Semi-Automatic Bottle Blowing Molding Machine

Quick Details

-

Neck Diameter(mm):

-

115 mm

-

Max.Bottle Diameter(mm):

-

350 mm

-

Max.Bottle Height(mm):

-

600 mm

-

Bottle Volume(ml):

-

20000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HENGMEI

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

Dimension(L*W*H):

-

2350*740*1880mm

-

Hollow part volume:

-

20L

-

Clamping Force (kN):

-

80

-

Power (kW):

-

25

-

Weight (KG):

-

1500 KG

-

Keywords:

-

Semi-Automatic Bottle Blowing Molding Machine

-

Suitable bottle:

-

5Gallon 20L PET Bottle

-

Bottle material:

-

PET Material

-

Cavity:

-

1-cavity

-

Maximum template area:

-

430*650mm

-

Max mold thickness:

-

410mm

-

Min mold thickness:

-

250mm

-

Clamping force:

-

80KN

-

Power:

-

25kw

-

Product name:

-

Semi-Automatic Bottle Blowing Molding Machine

Products Description

Equipment performance description and characteristics:

The HM-S3L2C semi-automatic bottle blowing machine is designed and improved on the basis of a manual bottle blowing machine, meeting CE standards. Controlled by a microcomputer, the technical parameters involved can be more accurately controlled. Easy to operate, safe, only one person is required, and no special training is required. The HM-S3L2C semi-automatic bottle blowing machine can blow carbonated beverage bottles, mineral water bottles, cosmetics bottles, hot filling bottles, especially oil bottles with handles.

Characteristic

1. Blown 20liter PET bottles (1 cavity)

2. Using a mold with two cavities to blow a 20-liter bottle can yield 150-400 bottles per hour.

3. Advanced PLC control system, time control can be precise to 0.01 seconds.

4. Special air storage devices.

5. Infrared bottle embryo heater.

6. Different heating lamps are equipped with independent temperature control devices to ensure ideal heating effect for the bottle embryo.

7. The direction of the heating lamp tube can be adjusted according to different bottle embryos.

8. Only one person is required for operation, and no special training is required.

9. Easy installation and startup.

10. The scrap rate of finished products is less than 0.3%

2. Using a mold with two cavities to blow a 20-liter bottle can yield 150-400 bottles per hour.

3. Advanced PLC control system, time control can be precise to 0.01 seconds.

4. Special air storage devices.

5. Infrared bottle embryo heater.

6. Different heating lamps are equipped with independent temperature control devices to ensure ideal heating effect for the bottle embryo.

7. The direction of the heating lamp tube can be adjusted according to different bottle embryos.

8. Only one person is required for operation, and no special training is required.

9. Easy installation and startup.

10. The scrap rate of finished products is less than 0.3%

Product Paramenters

|

Category

|

Project

|

Unit

|

HM-S20L1C

|

|

Finished Product

|

Raw Material

|

/

|

PET

|

|

|

Volume

|

L

|

20L

|

|

|

Output

|

PCS/H

|

150-400

|

|

|

Maximum Height

|

Mm

|

600

|

|

|

Maximum Diameter

|

Mm

|

350

|

|

Template Size

|

Theoretical Output

|

Mm

|

430*650

|

|

|

Max Mold Thickness

|

Mm

|

410

|

|

|

Min Mold Thickness

|

Mm

|

250

|

|

|

Clamping Force

|

KN

|

25T

|

|

|

Mold opening stroke

|

Mm

|

350

|

|

Host Power

|

Power

|

KW

|

25

|

|

Oven

|

Voltage / Frequency (Three-Phase)

|

V/HZ/HZ

|

380/50/60

|

|

Machine Size / Weight

|

Host

|

MM

|

2350*740*1880

|

|

|

|

KG

|

1500

|

|

|

Oven

|

MM

|

2670*660*1590

|

|

|

|

KG

|

560

|

Details Images

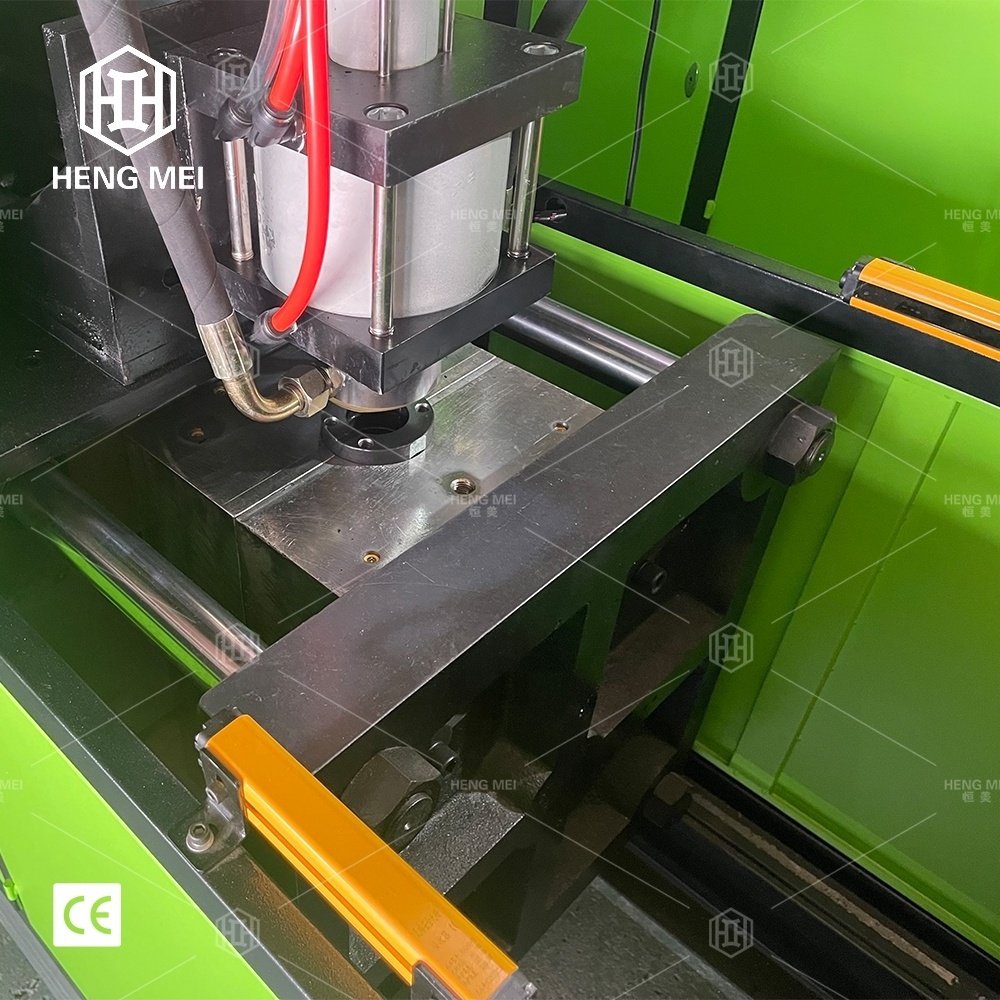

Bottle blowing device

Superior performance locking system

The HM-S3L2C semi-automatic bottle blowing machine adopts a three template clamping system, which provides a powerful clamping

force and meets the needs of bottle blowing pressure up to 35 Pa. It is equipped with an adjustment device to adjust the distance

between the front and middle templates and the position of the stretching cylinder according to the installation of different

molds.

force and meets the needs of bottle blowing pressure up to 35 Pa. It is equipped with an adjustment device to adjust the distance

between the front and middle templates and the position of the stretching cylinder according to the installation of different

molds.

Reliable safety devices

In order to ensure the safety of the machine and operators, the HM-S3L2C manual bottle blowing machine is equipped with two start

switches on both sides of the machine. These two switches can only be started when pressed simultaneously. In addition, there is

an emergency stop switch that stops the machine from running when encountering an emergency fault.

switches on both sides of the machine. These two switches can only be started when pressed simultaneously. In addition, there is

an emergency stop switch that stops the machine from running when encountering an emergency fault.

Powerful heating capacity

The HM series bottle embryo heating system uses infrared light tubes for heating. The powerful thermal radiation ability of

infrared can heat the bottle embryo to the required temperature in a short period of time, and the super strong penetration force

allows the interior and surface of the bottle embryo to be continuously and evenly heated.

infrared can heat the bottle embryo to the required temperature in a short period of time, and the super strong penetration force

allows the interior and surface of the bottle embryo to be continuously and evenly heated.

Ideal cooling device

The HM series bottle embryo heaters are equipped with air and water cooling devices to cool the heated bottle embryo bracket,

ensuring that the neck of the bottle embryo does not deform. The exhaust system on the heater ensures stable temperature during

the heating process of the bottle embryo.

ensuring that the neck of the bottle embryo does not deform. The exhaust system on the heater ensures stable temperature during

the heating process of the bottle embryo.

Independent heating control system

The HM series bottle embryo heater adopts an independent heating control device to achieve ideal heating effects for different

bottle embryos in each heating area. Each heating lamp has a voltage regulator to control the voltage of each heating lamp and

ensure its normal operation. The voltage value can be easily and conveniently monitored and adjusted through an LED display.

bottle embryos in each heating area. Each heating lamp has a voltage regulator to control the voltage of each heating lamp and

ensure its normal operation. The voltage value can be easily and conveniently monitored and adjusted through an LED display.

Multiple adjustment device

The multiple adjustment device is installed on the bottle embryo heater to enhance the performance of the machine. This device

can adjust the width and height of the drying channel according to different bottleneck sizes and heights. The size of the exhaust

port can also be adjusted according to different needs.

can adjust the width and height of the drying channel according to different bottleneck sizes and heights. The size of the exhaust

port can also be adjusted according to different needs.

Power system

The HM series bottle blowing machine reduces the external power supply to 24V through conversion, ensuring stable current and preventing electrical damage.

Gas control system

The HM series bottle blowing machine adds more valves in the gas pipeline to control the gas flow and ensure that the blown bottles are more perfect.

Air cylinder

Enlarge the bold cylinder to make the mold closing faster and more accurate.

Manually adjust the template position.

Manually adjust the template position.

Why Choose Us

FAQ

SEE HENGMEI MACHINERY HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE OF HENGMEI MACHINERY!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to Hengmei Machinery site.

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed & research team,we can send you engineers and make sure your after sales service.

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed & research team,we can send you engineers and make sure your after sales service.

HOW TO FIND HENGMEI MACHINERY?

● Search Alibaba,Google, Youtube and find suppliers and manufactrue and not traders.

● Visit exhibition in different countries.

● Send King Machine an request and tell your basic inquiry.

● Hengmei Machinery sales manager will reply you in short time and add instant chatting tool.

● Visit exhibition in different countries.

● Send King Machine an request and tell your basic inquiry.

● Hengmei Machinery sales manager will reply you in short time and add instant chatting tool.

Recommend Products

Beverage bottle blow molding machine .

Suitable bottle: 0.1-2L,3-10L,10-20L

Bottle material: PET PP

Capacity: 2cavities 3000-3500bph

4cavities 5500-6000bph

Semi automatic blow molding machine.

Suitable bottle: 0.1-2L,3-10L,10-20L

Bottle material: PET PP

Capacity: 2cavities 700-1200bph

4cavities 1700-2500bph

Capacity: 2cavities 700-1200bph

4cavities 1700-2500bph

All-electric blow molding machine.

Suitable bottle: 0.1-2L,3-10L

Bottle material: PET PP

Capacity: 2cavities 700-1200bph

4cavities 1700-2500bph

Capacity: 2cavities 700-1200bph

4cavities 1700-2500bph

Injection molding machine.

Extrusion blow molding machine.

Cap making machine.

Injection mold.

Preforms & Caps

Bottles.

Hot Searches