- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

customized

-

Weight:

-

100 kg

-

Application:

-

Producing Animal Feeds Pellets

-

Product name:

-

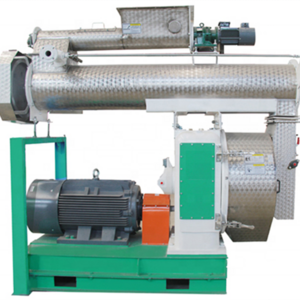

Animal Feed Pellet Plant

-

Name:

-

Wood Pellet Production Line

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Raw material:

-

Wood

-

Keywords:

-

Feed Mill Mixer

-

Model:

-

Recommend

-

Advantage:

-

Easy Operation High Efficiency

-

Feed types:

-

Livestock Pellet Feed

Quick Details

-

Max. Capacity:

-

15 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BTMA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

customized

-

Weight:

-

100 kg

-

Application:

-

Producing Animal Feeds Pellets

-

Product name:

-

Animal Feed Pellet Plant

-

Name:

-

Wood Pellet Production Line

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Raw material:

-

Wood

-

Keywords:

-

Feed Mill Mixer

-

Model:

-

Recommend

-

Advantage:

-

Easy Operation High Efficiency

-

Feed types:

-

Livestock Pellet Feed

Cattle and sheep feed crushe

Products Introduction

1. Efficiency: This equipment can mix a large amount of feed at one time, effectively improving work efficiency.

2. Automation: Some models are equipped with automatic weighing devices, which can set the adding amount at any time and automatically stir, reducing the burden of manual operation.

3. Uniformity: The stirred feed has high mixing uniformity and balanced energy intake, which is beneficial to improving the feed intake and feed utilization efficiency of cattle and sheep.

4. Economy: It can make full use of various forage grasses and crop straws without destroying the fiber components, maximizing the energy efficiency of the feed and saving 20% of roughage every year.

5. Convenience: Forward rotation is for mixing, reverse rotation is for discharging. Feed additives or water can also be added during the mixing process, which is easy to use.

6. Compatibility: It can be used with a hay cutter or a hay cutter and kneader. After cutting and kneading grass, pasture, straw, silage, yellow storage and other fodder, it can be mixed with grain, peanut shells, rice husks, corn , soybeans, soybean meal,tofu residue, etc. are mixed to make feed and fed to animals.

7. Applicability: Suitable for large and medium-sized feedlots, as well as farm-scale feedlots.

2. Automation: Some models are equipped with automatic weighing devices, which can set the adding amount at any time and automatically stir, reducing the burden of manual operation.

3. Uniformity: The stirred feed has high mixing uniformity and balanced energy intake, which is beneficial to improving the feed intake and feed utilization efficiency of cattle and sheep.

4. Economy: It can make full use of various forage grasses and crop straws without destroying the fiber components, maximizing the energy efficiency of the feed and saving 20% of roughage every year.

5. Convenience: Forward rotation is for mixing, reverse rotation is for discharging. Feed additives or water can also be added during the mixing process, which is easy to use.

6. Compatibility: It can be used with a hay cutter or a hay cutter and kneader. After cutting and kneading grass, pasture, straw, silage, yellow storage and other fodder, it can be mixed with grain, peanut shells, rice husks, corn , soybeans, soybean meal,tofu residue, etc. are mixed to make feed and fed to animals.

7. Applicability: Suitable for large and medium-sized feedlots, as well as farm-scale feedlots.

Structure

Product packaging and shipping

We will use the wood boxes to packing the machine.

Certifications

Packing And Delivery

Packing

We will load different sizes of packing according to different machine sizes, and small model is usually used by wooden box,

bigmodel is used by 20ft and 40ft container. All oil press machines are packed by Standard export carton to guarantee our products

well preserved during the transportation. Small spare parts are packed by wooden case or according to your requirements. If

exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to

the customer's special requirements.

Delivery

We are based on the actual needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt

of customer deposits we will manage production, regardless of the size of the equipment, we can deliver the goods in two

weeks,when the machines are finished, we will send machines after customers transfer the balanced payment.

Shipping

The machines are shipped from our factory to nearest port by truck , And when the machines are shipped from our port to clients

destination port by sea.

Hot Searches