- Product Details

- {{item.text}}

Quick Details

-

Rolling Speed (m/min):

-

4 - 8

-

Marketing Type:

-

New Product

-

Warranty of core components:

-

24 months

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Rbqlty

-

Weight (KG):

-

20000 KG

-

Motor Power (kw):

-

4.0 kw

-

CNC System:

-

TOUCH SCREEN

-

Name:

-

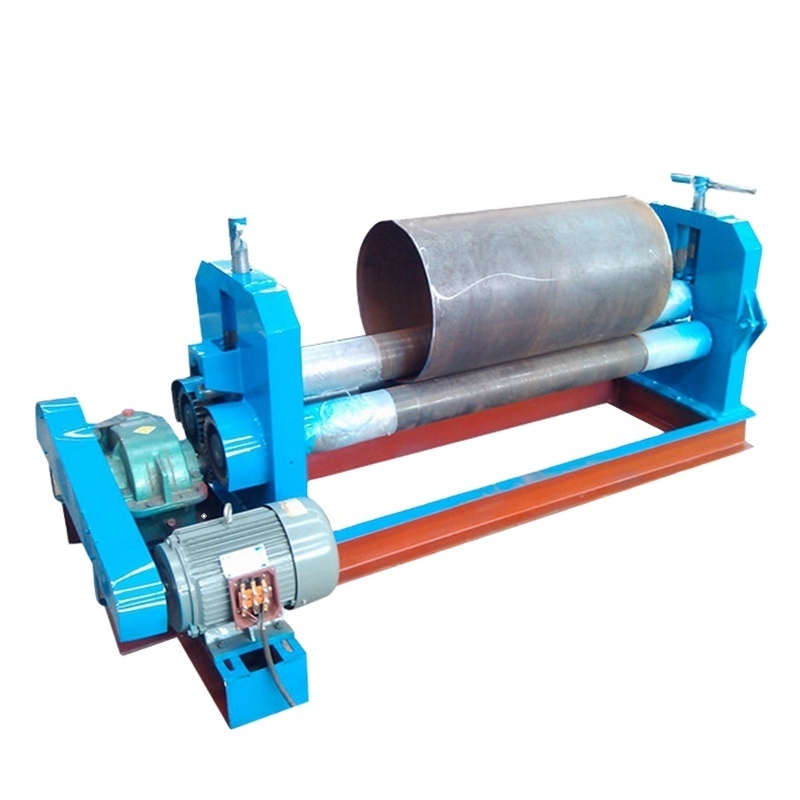

3-roller plate rolling machine

-

Control system:

-

NC control

-

Function:

-

rolling machine for sheet metal

-

Motor Power:

-

Mechanical 3-roller plate rolling machine

-

Color:

-

Blue White Black Red Yellow

-

Electrical components:

-

Schneider

-

Seal Ring:

-

Japan NOK

-

optional device:

-

Support rack

Quick Details

-

Max. Working Length (mm):

-

2500 mm

-

Max. Plate Thickness (mm):

-

2500 mm

-

No. of Roller:

-

3

-

Rolling Speed (m/min):

-

4 - 8

-

Marketing Type:

-

New Product

-

Warranty of core components:

-

24 months

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Rbqlty

-

Weight (KG):

-

20000 KG

-

Motor Power (kw):

-

4.0 kw

-

CNC System:

-

TOUCH SCREEN

-

Name:

-

3-roller plate rolling machine

-

Control system:

-

NC control

-

Function:

-

rolling machine for sheet metal

-

Motor Power:

-

Mechanical 3-roller plate rolling machine

-

Color:

-

Blue White Black Red Yellow

-

Electrical components:

-

Schneider

-

Seal Ring:

-

Japan NOK

-

optional device:

-

Support rack

Anhui manufacture 6mm thickness plate rolling machine price with Delivery to all over the world

Description:

Whole structure

1.The machine adopts 3-roller symmetrical structure with the upper roller moving vertically in the center between the lower rollers, wihch is achieved through the drive of the screw, the unt, the worm and the lead screw.

2.The two lower rollers rotates, and privideds the plate materials with torque through the engagement of the output gear of the moderator with the gear of the lower rollers.

3.Adapted for bending metal plate into round, arc, and so on. Its working principle is ratary benidng deformation. This product is widely used in chemical industry, cement, shipbuilding, boiller, aviation, water control project, power transmission tower, metal structure and the industry of making machinery.

Main parts:

1.Working rollers: roughcast roller--- forging--- annealing--- peeled--- flaw detection--- rough machining--- quenching and tempering treatment--- flaw detection again--- semi-finish machining--- finish machining

2..Large forigings: cylinder body, gear, gear shaft: roughcast-forging-surface imspection-roughing-flaw detection-heart treatment-semi-finishing-finishing

3.Welding structure: racks, base, gearbox cover :eliminating internal stress treatment.

4 The electric control parts :the bending speed of main transmission part is 5.5m/min, controlled by gearbox and brake through electric motor.

5 The second motor wiring accessories and necessary materials (wire diagram from motor cabinet to actuator)

6 The technical data.operation manual,electrical diagram.

Lead time

20 to 30 days

Payment Method

30% T/T in advance, the balance paid before shipping

|

Packaging

|

|

|

|

Size

|

According to final product

|

|

|

Weight

|

According to final product

|

|

|

Packaging Details

|

Plastic film packge

plywood box package

|

|

|

Delivery Details

|

FCA to your consignee

FOB PORT to Shanghai

CIF PORT in your country

|

|