- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

CN;

-

Brand Name:

-

China Guo jin

-

Product name:

-

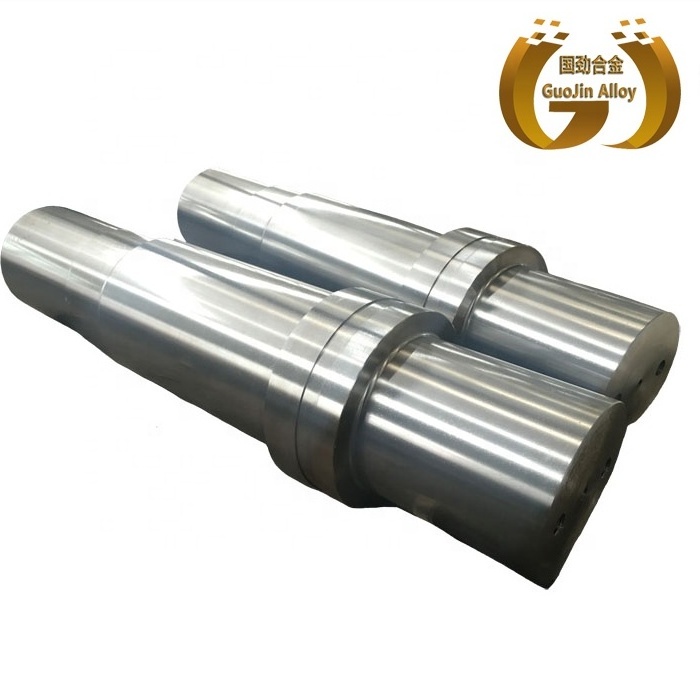

Shaft Collar

-

Application:

-

Industrial Equipment

-

Process:

-

Forging+machining+heating Treatment

-

Name:

-

Stainless Steel Cnc Machining Shaft

-

Surface Treatment:

-

Chrome Plating

-

Type:

-

Machining Services

Quick Details

-

Material:

-

4140 4130 4340 8620, 30CrNiMo8, 34CrNiMo6

-

Torque Capacity:

-

Contact

-

Model Number:

-

100-10000

-

Place of Origin:

-

CN;

-

Brand Name:

-

China Guo jin

-

Product name:

-

Shaft Collar

-

Application:

-

Industrial Equipment

-

Process:

-

Forging+machining+heating Treatment

-

Name:

-

Stainless Steel Cnc Machining Shaft

-

Surface Treatment:

-

Chrome Plating

-

Type:

-

Machining Services

Product Description

Products Description

|

State of health:

|

new

|

|

|

|

|

Guarantee:

|

6 months

|

|

|

|

|

Applicable industry:

|

Mechanical repair shop, manufacturing plant, energy and mining, cement plant

|

|

|

|

|

Birthplace:

|

Jiangsu, China

|

|

|

|

|

Brand:

|

Jin Guo

|

|

|

|

|

product name:

|

Bearing

|

|

|

|

|

Manufacturing process

|

Forging + processing + heat treatment

|

|

|

|

|

Certification:

|

ISO9001 certification

|

|

|

|

Application Industry

Forgings need to be consistent in every piece, without any porosity, extra space, inclusions or other flaws. The components produced by this method have a high ratio of strength to weight. These components are commonly used in aircraft structures. The advantages of forgings include stretchable length and shrinkable cross section; shrinkable length and stretchable cross section; changeable length and changeable cross section. The types of forgings are: free forging/hand forging, hot die forging/precision forging, top forging, roll forging and die forging. 1. Aircraft forgings Calculated by weight, about 85% of the components on the plane are forgings. Aircraft engine turbine disks, rear axle journals, blades, wing spars, fuselage rib plates, wheel brackets, inner and outer cylinders of landing gear, etc. are all important forgings related to aircraft safety. Aircraft forgings are mostly made of precious materials such as high-strength wear-resistant and corrosion-resistant aluminum alloys, titanium alloys, and nickel-based alloys. In order to save materials and save energy, aircraft forgings are mostly produced by die forging or multi-directional die forging presses. Car forging is calculated by weight, and there are 71.9% of forgings on the car. The general automobile is composed of 15 parts such as the body, the trunk, the engine, the front axle, the rear axle, the frame, the gearbox, the transmission shaft, and the steering system. The characteristics of automobile forgings are complex appearance, light weight, poor working conditions, and safety. High standard. Such as crankshafts, connecting rods, camshafts used in automobile engines, front beams required for front axles, steering knuckles, half shafts used in rear axles, half shaft bushings, transmission gears in axle boxes, etc. Key forgings for the safe operation of automobiles. 2. Diesel engine Diesel engine is a kind of power machinery, it is commonly used as an engine. Take the large diesel engine as an example, the forgings used are cylinder head, main journal, crankshaft flange output shaft, connecting rod, piston rod, piston head, crosshead pin, crankshaft transmission gear, ring gear, intermediate gear and dye pump More than ten kinds of body. 3. Marine forgings Marine forgings are divided into three categories, main engine forgings, shaft forgings and rudder forgings. The main engine forging is the same as the diesel engine forging. Shaft forgings include thrust shaft, intermediate shaft and stern shaft. Rudder forgings include rudder stock, rudder post, and rudder pin. 4. Weapon forgings Forgings occupy an extremely important position in the weapon industry. By weight, 60% of the tanks are forgings. Barrels, muzzle brakes and breech in artillery, rifled barrels and triangular bayonets in infantry weapons, rocket and submarine deep-water bomb launchers and mounts, stainless steel valve bodies for high-pressure coolers in nuclear submarines, shells, Bullets, etc. are all forged products. In addition to steel forgings, other materials are used to make weapons. 5. Petrochemical Forgings are widely used in petrochemical equipment. Such as manholes and flanges of spherical storage tanks, various tube sheets required for heat exchangers, full-forged cylinders (pressure vessels) of butt welding flange catalytic cracking reactors, cylinder sections used in hydrogenation reactors, and fertilizers The top cover, bottom cover, head, etc. required by the equipment are all forgings. 6. Mine forgings Calculated by the weight of equipment, the proportion of forgings in mining equipment is 12-24%. Mining equipment includes: mining equipment, hoisting equipment, crushing equipment, grinding equipment, washing equipment, sintering equipment. 7. Nuclear power forging Nuclear power is divided into two types: pressurized water reactors and boiling water reactors. The main large forgings of nuclear power plants can be divided into two categories: pressure shells and internal components. The pressure shell includes: cylinder flange, nozzle section, nozzle, upper cylinder body, lower cylinder body, transition section of cylinder body, bolts, etc. The internal components of the reactor work under severe conditions such as high temperature, high pressure, strong neutron radiation, boric acid water corrosion, erosion, and hydraulic vibration. Therefore, 18-8 austenitic stainless steel is used for production.

Hot Searches