Decho is a verified supplier by Alibaba and TUV .

We have 20 years of export experience serving global quality customers.Have a professional R&D team and technical engineers.Realize the integrated service from design to installation and commissioning.Our products provide customer more convenient in their business and expect to have more cooperate in future.

Main products are as follows:

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Decho

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

560cm * 150cm * 150cm

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

Roll Forming Machine

-

Usage:

-

Roof

-

Roller material:

-

Gcr15

-

Cutting blade material:

-

SKD11

-

control system:

-

PLC(imported Brand)

-

Roller stations:

-

13 Stations

-

Main frame:

-

300-450 H steel

-

Decoiler:

-

5T Manual Decoiler

-

Profiles:

-

Cold Roll Forming Machine

-

Certification:

-

CE

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Decho

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

560cm * 150cm * 150cm

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

Roll Forming Machine

-

Usage:

-

Roof

-

Roller material:

-

Gcr15

-

Cutting blade material:

-

SKD11

-

control system:

-

PLC(imported Brand)

-

Roller stations:

-

13 Stations

-

Main frame:

-

300-450 H steel

-

Decoiler:

-

5T Manual Decoiler

-

Profiles:

-

Cold Roll Forming Machine

-

Certification:

-

CE

Product information

1. Product Profile

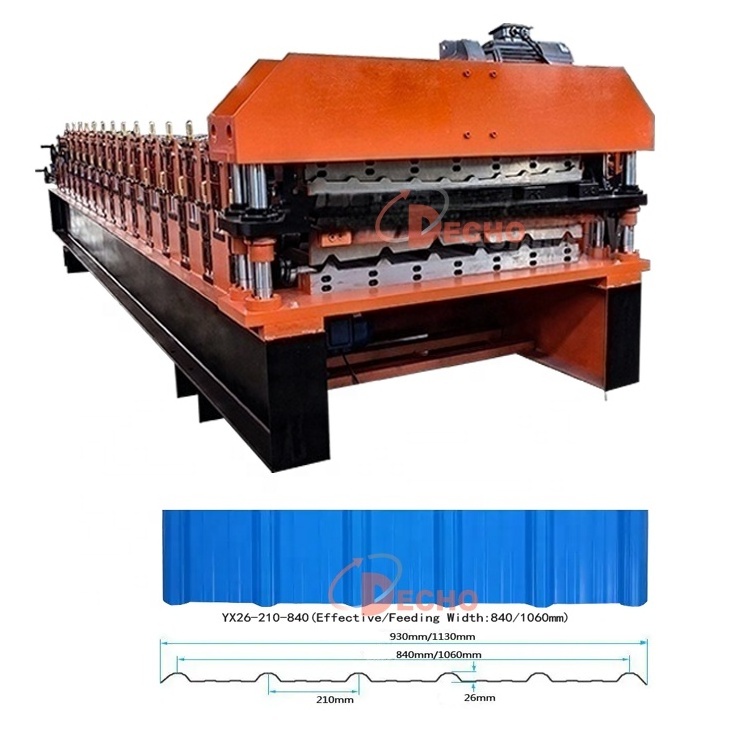

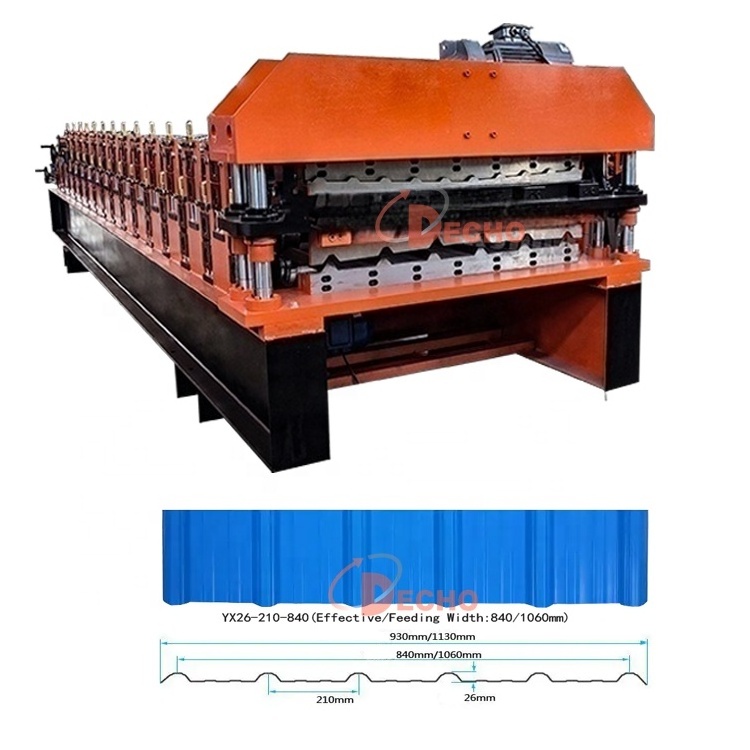

This high speed double layer roof sheet roll forming machine was customized by an American customer.

This machine has upgraded all components from the technical standards of the original double-layer tile machine. Equipped with a 350H steel precision milling frame, 20mm middle plate, 40 # chromium steel shaft, GCr15 roller, SKD11 shear blade, electric uncoiling, electric shearing and other configurations. It is easy to operate, runs stably, and can achieve a production efficiency of

30+ meters per minute

.

This machine perfectly combines two types of tiles and can produce the roof or wall panels that customers need, such as trapezoidal tiles, corrugated tiles, and glazed tiles.

It has reasonable structure, beautiful appearance, with advantage of saving space, easy operate and especially welcomed by the customer with limit area or site.

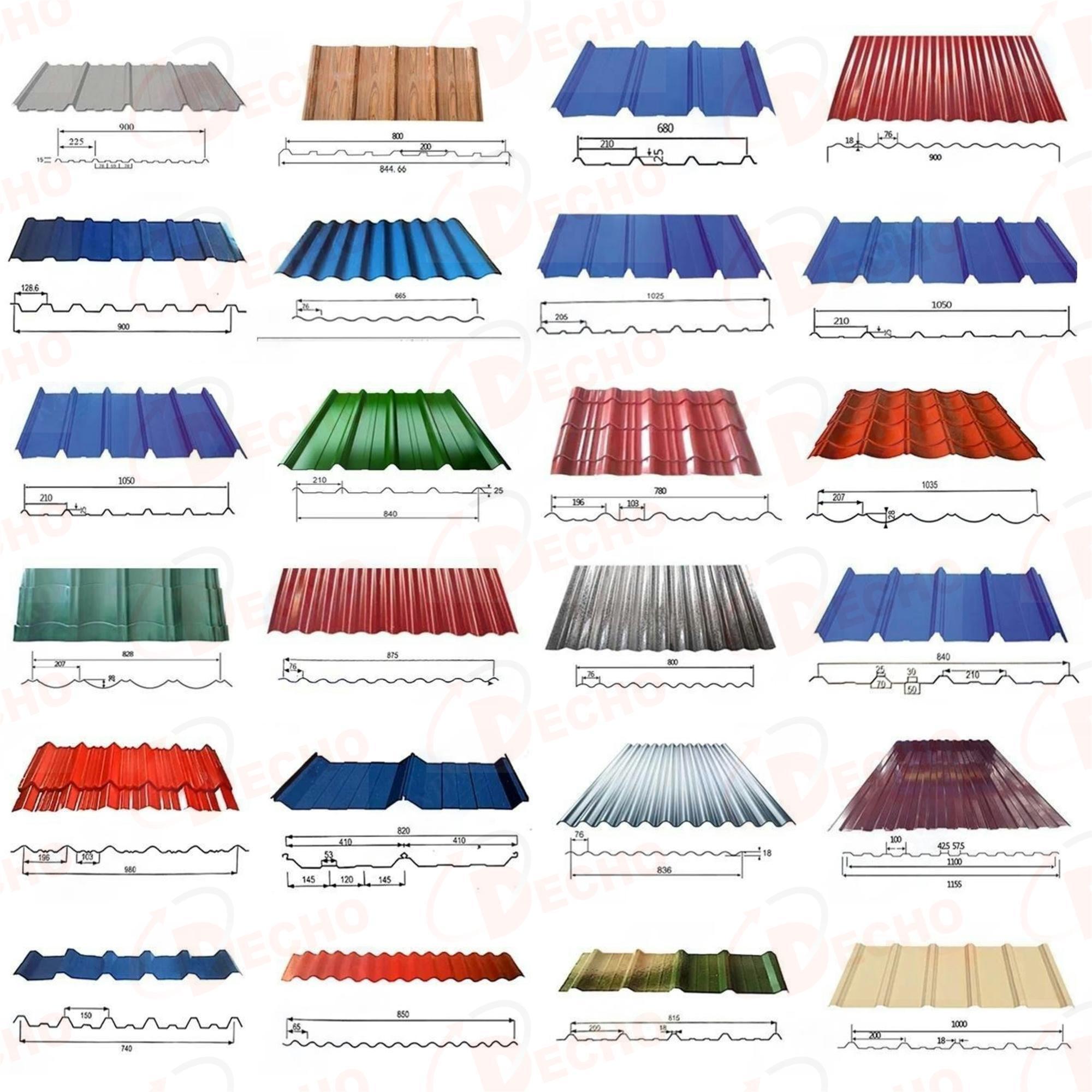

2. Typical tile type drawings

As the manufacturer of the roll forming machinery, we can produce most of the products according to your requirements, not just the size of the products on this page.

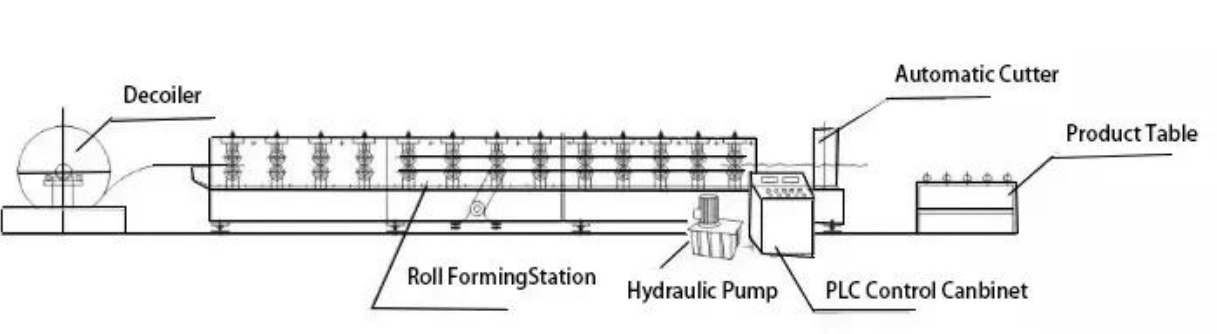

3. Work Flow

Capacity of the entire production line

is 20-30 m/min. It consists of 5 parts.

Un-coiler→Feeding material →Roll forming→Auto cutting→

Products receiving table, but It only takes 1-2 worker.

4. Equipment List

|

NUM

|

Equipment Name

|

Quantity

|

|

1

|

Uncoiling Device

|

1 set

|

|

2

|

Forming Main Machine

|

1 set

|

|

3

|

Hydraulic Cutting System

|

1 set

|

|

4

|

Material Receiving Table

|

1 set

|

|

5

|

PLC Control System

|

1 set

|

|

6

|

Supporting Accessories

|

1 set

|

5. Product Specification

|

Item

|

Parts

|

Specification & Description

|

|

1.Raw Material

|

Type

|

GI / GL /PPGI / PPGL /Customization

|

|

|

Thickness(mm)

|

0.3-0.8

|

|

2.Un-coiler Device

|

Type

|

Manual / Electric / Hydraulic Decoiler(optional)

|

|

|

Bearing(Tons)

|

5T/8T/10T(optional)

|

|

|

Way of working

|

Manual / Electric / Hydraulic tensioning crank. The center of the four-bar linkage is supported outward.

|

|

|

Inner contraction range

|

φ450-550mm

|

|

|

Coil Inner diameter

|

φ480-500mm

|

|

|

Panel Width(mm)

|

940-1220mm(customizable)

|

|

3.Forming host

|

|

Material:350H steel

The main frame is welded with 350H steel frame. The machining table uses CNC milling of 16mm steel plates.The frame has undergone aging treatment to eliminate internal stress and has good stability.

Processing: CNC milling - precision machining - aging treatment

|

|

|

|

Material : 45#steel

Thickness: 20mm Processing :laser cutting |

|

|

Shaft

|

Material : 40Cr solid shaft

Diameter : 80mm Processing : Precision machining, heat treatment, precision grinding |

|

|

Rollers

|

Material: Gcr15 high-carbon chromium bearing steel

Processing : Quenching, precision turning, polishing treatment |

|

|

Roller Station

|

12-14 stations or Customization

|

|

|

Transmission

|

Specifications:1.2 inch chain wheel with gear transmission

Processing :Quenching heat treatment Gear oil:18 # hyperbolic gear oil |

|

|

|

Power:7.5KW

Brand:Lichao(optional) Reducer: Cycloidal reducer Protection level:IP55 Explosion-proof level:ExdIICT4 |

|

|

Type

|

Automatic high-speed electric shearing for Four guide pillars

|

|

|

|

material:SKD11

Processing :precision grinding, cutting, heat treatment.

Service life: 500000 times

|

|

|

Pump

|

hydraulic pressure:10-12mpa

Hydraulic oil: 46# |

|

|

Motor for cutter

|

Power: 3KW

|

|

5.Receiving rack

|

Type

|

manual / Electric receiving rack

|

|

|

PLC Control System

|

Plc brand:Delta (optional)

Text control box:Vertical LCD touch screen control box/Swing arm LCD touch screen control box Language: English / Chinese / Customized |

|

|

Inverter

|

Rated power:7.5KW

|

6. Product details

Un-coiler

Usage:

Used to support steel coils, and uncoil and straighten the coil into the feeding port.

Steel coil width : 940- 1220 mm. (According to your actual drawing)

Loading capacity: 5T/8T/10T(optional)

Inner diameter: 450-550mm

Steel coil width : 940- 1220 mm. (According to your actual drawing)

Loading capacity: 5T/8T/10T(optional)

Inner diameter: 450-550mm

Feeding port

Usage:

Applied to control the width and position of the steel sheet, which is guided into the correct position of machine to make sure the panel is neat and parallel.

Other Accessorie: The hand knife can cut the raw materials and control the length of the feed, thereby saving raw materials.

Other Accessorie: The hand knife can cut the raw materials and control the length of the feed, thereby saving raw materials.

Roll forming system

Shaft Material:

40Cr.

Roller Material: GCr15.

Characteristic: After being forged, polished, heat-treated and finally chromeplated.

Roller Material: GCr15.

Characteristic: After being forged, polished, heat-treated and finally chromeplated.

Auto Cutting system

Blade material:

SKD11.

Characteristic: Quenching before heat treatment can ensure the smoothness and hardness of the surface.

Cutting method: Hydraulic / Electric cutting (stable cutting with high speed and low noise)

Characteristic: Quenching before heat treatment can ensure the smoothness and hardness of the surface.

Cutting method: Hydraulic / Electric cutting (stable cutting with high speed and low noise)

PLC control system

Usage:

Control the length, quantity, speed, accuracy, and other parameters of the product through programming settings. There aretwo counting modes: automatic and manual.

Language:

English, Chinese, or customization. It is easy to operate and use.

Main Motor

Powe

r:5.5KW

Brand :Lichao(optional)

Reducer : Cycloidal reducer

Protection level :IP55

Explosion-proof level :ExdIICT4

Brand :Lichao(optional)

Reducer : Cycloidal reducer

Protection level :IP55

Explosion-proof level :ExdIICT4

Middle plate

Material

: 45#steel

Thickness : 20mm

Processing :laser cutting

Thickness : 20mm

Processing :laser cutting

Electric control box

Voltage:380V/60HZ/3PH electricity or Customization

Inverter:7.5KW

Inverter:7.5KW

Receiving rack

Usage: It adopts welded steel and supported roller to transmit the products, which is used to collect the finished products.

Packaging & Shipping

1. One container (20ft or 40ft ) for loading one set machine with manual decoiler and receiving rack.

2. The whole wiped Anti Rust Oil, PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

2. The whole wiped Anti Rust Oil, PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

Related Products

About Us

1.About Decho

|

Roofing forming machine

|

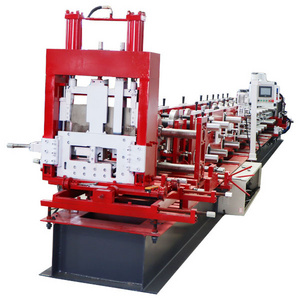

Purlin forming machine

|

Storage Rack System forming machine

|

|

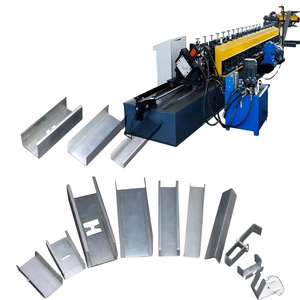

Light steel keel forming machine

|

Floor decking forming machine

|

Shutter door forming machine

|

|

Highway Guardrall forming machine

|

Solar Panel Bracket forming machine

|

Truss roll forming machine

|

|

Channel roll forming machine

|

Ceiling roll forming machine

|

Slitter & cutter machine

|

|

Leveling & cutting machine

|

Bending machine

|

Decoiler (uncoiler)

|

2. Certificate

3. Customer Project

Project in Thailand

Project in India

Project in Russia

FAQ

Q1: Are you a manufacturer?

A1:Yes, we are professional manufacturer of the roll forming machine.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 2-5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing, Shanghai or Guangzhou, how to visit your company?

A8: Please contact me and I will arrange a suitable itinerary for you.

A1:Yes, we are professional manufacturer of the roll forming machine.

Q2. What are the main key points for selecting right machines?

A2: Whole structure, Roller Shaft, Roller Material, Motor&Pump, and Control system. As the new buyer, please kindly know that price not the final point. Good quality is for long-term business cooperation.

A2: Whole structure, Roller Shaft, Roller Material, Motor&Pump, and Control system. As the new buyer, please kindly know that price not the final point. Good quality is for long-term business cooperation.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 2-5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing, Shanghai or Guangzhou, how to visit your company?

A8: Please contact me and I will arrange a suitable itinerary for you.

Hot Searches