- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Weight:

-

3200 kg

-

Max. Unwind Diameter:

-

800mm (31.5")

-

Max. Rewind Diameter:

-

800mm (31.5")

-

Max. Printing Width:

-

350mm (13.77")

-

Max. Die Cutting Width:

-

350mm (13.77")

-

Intermittent Die Cutting Speed:

-

60m/min

-

Full Rotary Max. Mechanical Speed:

-

120m/min

Quick Details

-

Type:

-

printing and die cutting machine

-

Production Capacity:

-

120 m/min

-

Max. workable width:

-

350mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Weight:

-

3200 kg

-

Max. Unwind Diameter:

-

800mm (31.5")

-

Max. Rewind Diameter:

-

800mm (31.5")

-

Max. Printing Width:

-

350mm (13.77")

-

Max. Die Cutting Width:

-

350mm (13.77")

-

Intermittent Die Cutting Speed:

-

60m/min

-

Full Rotary Max. Mechanical Speed:

-

120m/min

Product Description

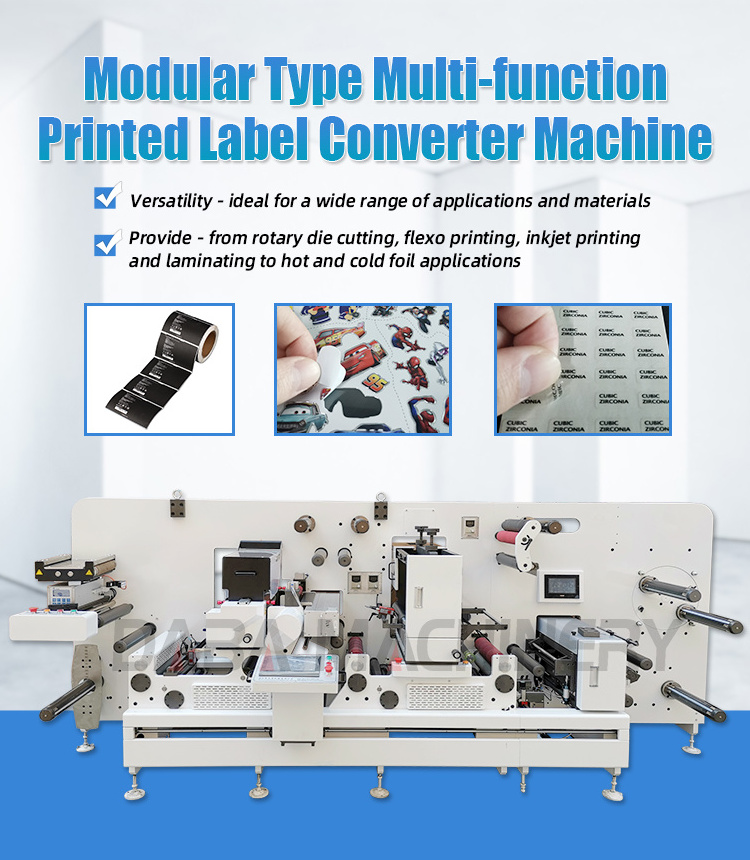

Modular Type multi-function printed label converter machine

1.Versatility - ideal for a wide range of applications and materials

2.

provide - from rotary die cutting, flexo printing, screen printing,inkjet printing and laminating to hot and cold foil applications

The machine can increase inspecting system, cross-cut, IML die-cutting, turret rewinder, etc. according to customer exact

requirement. using the advanced servo control system, user-friendly operation panel, greatly improve product quality and

production efficiency, with the latest full-rotary and intermittent interchangeable technology; suitable for digital printing

label short and medium-length orders after die cutting machine.

|

Machine Parameter

|

|

|

|

Max. Web Width

|

370mm (14.56")

|

|

|

Max. Unwind Diameter

|

800mm (31.5")

|

|

|

Max. Rewind Diameter

|

800mm (31.5")

|

|

|

Max. Flexo Printing Width

|

350mm (13.77”)

|

|

|

Max. Die Cutting Width

|

350mm (13.77")

|

|

|

Full Rotary Max. Mechanical Speed

|

120m/min

|

|

|

Intermittent Die Cutting Speed

|

60m/min

|

|

|

Max. Flexo Printing Speed

|

60m/min

|

|

|

Optional Printing Cylinder

|

80T-210T

|

|

|

Standard Printing Cylinder

|

140T

|

|

|

Adhesive Die Cutting Precision Accuracy (cut 1st layer)

|

±0.15mm

|

|

|

Die-cutting Precision Accuracy (cut totally)

|

±0.25mm

|

|

|

Die-cutting Positioning Method

|

Color sensor

|

|

|

Optional Magnetic Cylinder

|

80T ~ 210T

|

|

|

Standard Magnetic Cylinder

|

140T

|

|

|

Power Consumption

|

19 ~ 21KW

|

|

|

Air Supply (bar)

|

0.6 kpa

|

|

|

Rating Voltage

|

380V 50Hz

|

|

|

Roting Current

|

50A

|

|

|

Machine Weight

|

About 3200Kgs

|

|

Application and Sample

Applicable Material:

* Self-adhesive paper,Self-adhesive thermal paper,thermal paper ATM etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

Applicable Industry:

* Food product label, Anti-counterfeit label, Daily chemical products label, Medicines label, Chemical label, Paper cup paper,Blank label,etc.

Details Images

Unwinding Unit

Independent, servo-driven unwinder with closed-loop tension control and integrated reel lift.

Web Guide

Electronic web guide with ultrasonic edge guide sensor.

Splice Table

UV LED Dryer

Lower temperature, more energy saving, longer service life

SEMI OR FULL ROTARY DIE CUTTING UNIT

Independent and servo-driven. Magnetic or solid/engraved cylinders.

Waste Matrix Unit

1. 3 inch air shaft (switch on/off)

2. With a driven capstan roller with adjustable tension control for quickly removing large areas of waste.

2. With a driven capstan roller with adjustable tension control for quickly removing large areas of waste.

Rewinding Unit

1. Standard: One rewinding shaft for down rewinding

2. Optional airshaft: 1inch / 1.5inch

3. with automatic taper tension control

4. with automatic counter single, twin or turret – to complete your work efficiently.

Control Panel

1. With movable type design

2. With a 10inch screen

3. With English language / specified language operation panel

4. Kinco brand (standard) / Simense brand (optional)

Slitting Unit

scissor, razor or crush, with time-saving automatic knife setting units.

Cross Cutting Unit

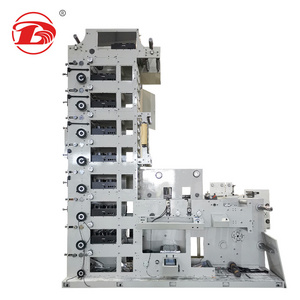

Flexo Printing Unit

1. Semi rotary / Full rotary Printing Model Exchangable

2. With 140T Printing Cylinder(standard) *1 pc

3. With ceramic anilox cylinder

4. With chiller drum

5. With UV dryer

6. With color tracking sensor

2. With 140T Printing Cylinder(standard) *1 pc

3. With ceramic anilox cylinder

4. With chiller drum

5. With UV dryer

6. With color tracking sensor

Glazed mimeograph, the printed ink is not easy to fall off, and the quality is better

Hot Stamping Unit

Cold-foil and super varnish with two pneumatic shafts and unwind/rewind.

CORONA TREATER

High quality Corona treater. Up to 42 dyne with filmic materials. Recommended for synthetic substrates prior to coating, and cold foiling.

Flatbed Die Cutting Unit

Screen Printing Unit

Back Side Cutting

Dust Remove Unit

In Factory Photo

Packing & Delivery

Our Service

1.Purchase Service

DABA COMPANY have a specialize and efficiency working team.If you are new onthe printing and packing area Some samples of your

products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

DABA COMPANY have a specialize and efficiency working team.If you are new onthe printing and packing area Some samples of your

products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

2.Shipping Service

DABA COMPANY have a spcialized and independent department which just for

shipping the buyer's goods.The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

DABA COMPANY have a spcialized and independent department which just for

shipping the buyer's goods.The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

3.Installation Services

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to

installation and preoperation ofmachines But the buyer need to surpply the round trip tickets food hotel cost.

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to

installation and preoperation ofmachines But the buyer need to surpply the round trip tickets food hotel cost.

4.Clients Training Services

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company

technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company

technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

5.After Sales Service

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with

machines.Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with

machines.Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

Hot Searches