- Product Details

- {{item.text}}

Quick Details

-

Machine type:

-

Metal Ore Magnetic Beneficiation Equipment

-

Price:

-

Negotible

-

Model:

-

CTB/CTS

-

Motor:

-

AC Motor

-

Features:

-

High Recovery Rate Easy

-

Capacity:

-

50-300 Tph

-

Name:

-

Mineral Copper Ore Flotation Machine Plant

-

Color:

-

Customers' Requirements

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Application:

-

Dividing minerals into magnetic and non-magnetic materials

-

Keywords:

-

Flotation Separator

-

Machine type:

-

Metal Ore Magnetic Beneficiation Equipment

-

Price:

-

Negotible

-

Model:

-

CTB/CTS

-

Motor:

-

AC Motor

-

Features:

-

High Recovery Rate Easy

-

Capacity:

-

50-300 Tph

-

Name:

-

Mineral Copper Ore Flotation Machine Plant

-

Color:

-

Customers' Requirements

Coal Preparation Washing Plant Froth Flotation Cell Machine

Our Product

Introduction of Coal Preparation Washing Plant Froth Flotation Cell Machine

The impeller has a double-sided blade with backward tilting, which can realize double circulation of slurry in the tank; the gap between the impeller and the cover plate is large, and the air intake is large; the circumferential speed of the impeller is low, and the life of the wearing parts is long; the forward inclined groove body has a small dead angle , foam movement speed; large inspiratory capacity, low energy consumption; long life of wearing parts; conducive to coarse-grain mineral flotation; mechanical agitation, self-priming, self-priming slurry

Technology Data of Coal Preparation Washing Plant Froth Flotation Cell Machine

| Model |

volume

(m3) |

processing power

(m3/min) |

impeller diameter

(mm) |

impeller speed

(r/min) |

main motor power

(kW) |

Scraper motor power (kW) |

tank weight

(T/slot) |

| SF0.37 | 0.37 | 0.2-0.4 | 300 | 442 | 1.5 | 1.1 | 0.45 |

| SF0.7 | 0.7 | 0.3-1 | 350 | 400 | 3 | 1.1 | 0.9 |

| SF1.2 | 1.2 | 0.6-1.2 | 450 | 312 | 5.5 | 1.1 | 1.4 |

| SF2.8 | 2.8 | 1.5-3.5 | 550 | 268 | 11 | 1.1 | 2.2 |

| SF4 | 4 | 2-4 | 650 | 235 | 15 | 1.5 | 2.6 |

| SF8 | 8 | 4-8 | 760 | 191 | 30 | 1.5 | 4.3 |

| SF16 | 16 | 5-16 | 850 | 190 | 45 | 1.5 | 7.4 |

| SF20 | 20 | 5-20 | 730 | 186 | 30*2 | 1.5 | 9.8 |

(part data of our magnetic separator, more information welcome to contact us)

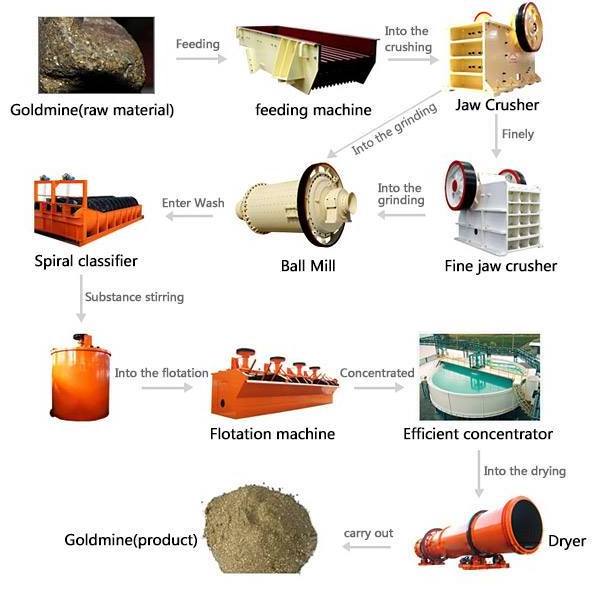

Working principle of Coal Preparation Washing Plant Froth Flotation Cell Machine

The working principle of the SF flotation separator , when the impeller rotates, the slurry in the upper and lower impeller chambers generates centrifugal force under the action of the upper and lower blades and is twisted to the periphery, so that a negative pressure zone is formed in the upper and lower impeller chambers. At the same time, the slurry in the upper part of the cover plate is sucked into the upper impeller cavity through the circulation hole on the cover plate to form a slurry circulation. When the lower blade pulls out the slurry around, the lower slurry is replenished to the center, thus forming a lower circulation of the slurry. The air is sucked into the upper impeller chamber through the suction pipe and the central cylinder, and is mixed with the sucked slurry to form a large number of fine bubbles, which are uniformly dispersed in the groove through the cover plate to form mineralized bubbles. The mineralized bubbles float up to the foam layer and are scraped off by the scraper to form a foam product.

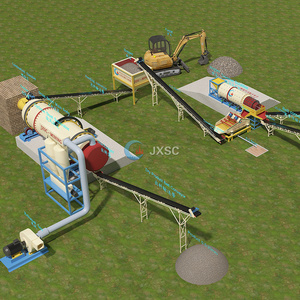

Working Flow of Coal Preparation Washing Plant Froth Flotation Cell Machine

Our Service

Pre-Sales Service

♥Online interactive service

♥Offline interactive service

♥Solution design service

♥Visit reception service

After-Sales Service

♥Installation and debugging service

♥Training service

♥Other more service(Clients have any needs or problems; our engineer can take plane and get the worksite to provide service in 8 hours.)

Packing&Shipping

1.Seaworthy packing with sheet, fixed box, etc.

2. Container Loading

3. Delivery time: 15 days after receiving deposit.

4. All payment terms are available.

Our Company

Shanghai Clirik Machinery Co., Ltd located in Pudong New district of Shanghai china, as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of grinding mill, from coarse grinding mill, fine grinding mill and ultra fine grinding mill, grinding mill related equipment, such as powder modifying machine, powder packing machine.powder conveying system, etc. We have devoted into grinding field for more than 30 years, we beliveonly focus can be professional.

Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Our Certification

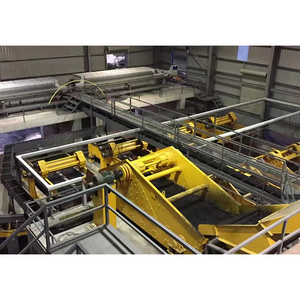

Our Working Site

Our Customers Visiting

Our Exhibition

FAQ

1. Quality control

All the equipment offered by Shanghai Clirik Machinery Co., Ltd. are produced by China national standard drawings, nonstandard equipment will be produced by the drawings confirmed by clients. Clirik Machinery strictly follows ISO 9001: 2008 Quality management system. Most equipment will be test for at least 8 hours in the factory before delivery. There is record in computer for each equipment, spares can be easily confirmed when it is necessary.

2. Way of payment

Welcome clients place the order by alibaba online one-touch! Deya also offers various ways of payment, T/T, against copy of B/L, L/C, D/A, D/P, West union, etc. All can be negotiated.

3. Delivery time

Normal delivery time within 10 to 20 working days, complete production line or larger equipment may take longer. Exact delivery shall be confirmed when place the order.

4. Trade terms

Typically EXW, FOB, CIF, CFR, DAF follows International Rules for the Interpretation of Trade Terms 2010(INCOTERMS 2010).(you are also welcome to take the rule of Alibaba Trade Assurance)

5. Shipping lines

Priority rule based on clients' request, and freight cost, service, shipping date, date of arrival shall be considered.

6. Installation

Clirik has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians’ round way air tickets, salary(shall be confirmed before leaving), food and lodging, most importantly to guarantee the technicians’ safety.

7. Equipment warranty

Equipment from Shanghai Clirik Machinery Co., Ltd. with 18 months warranty, can be extended to 12 months as request.

Shanghai Clirik Machinery