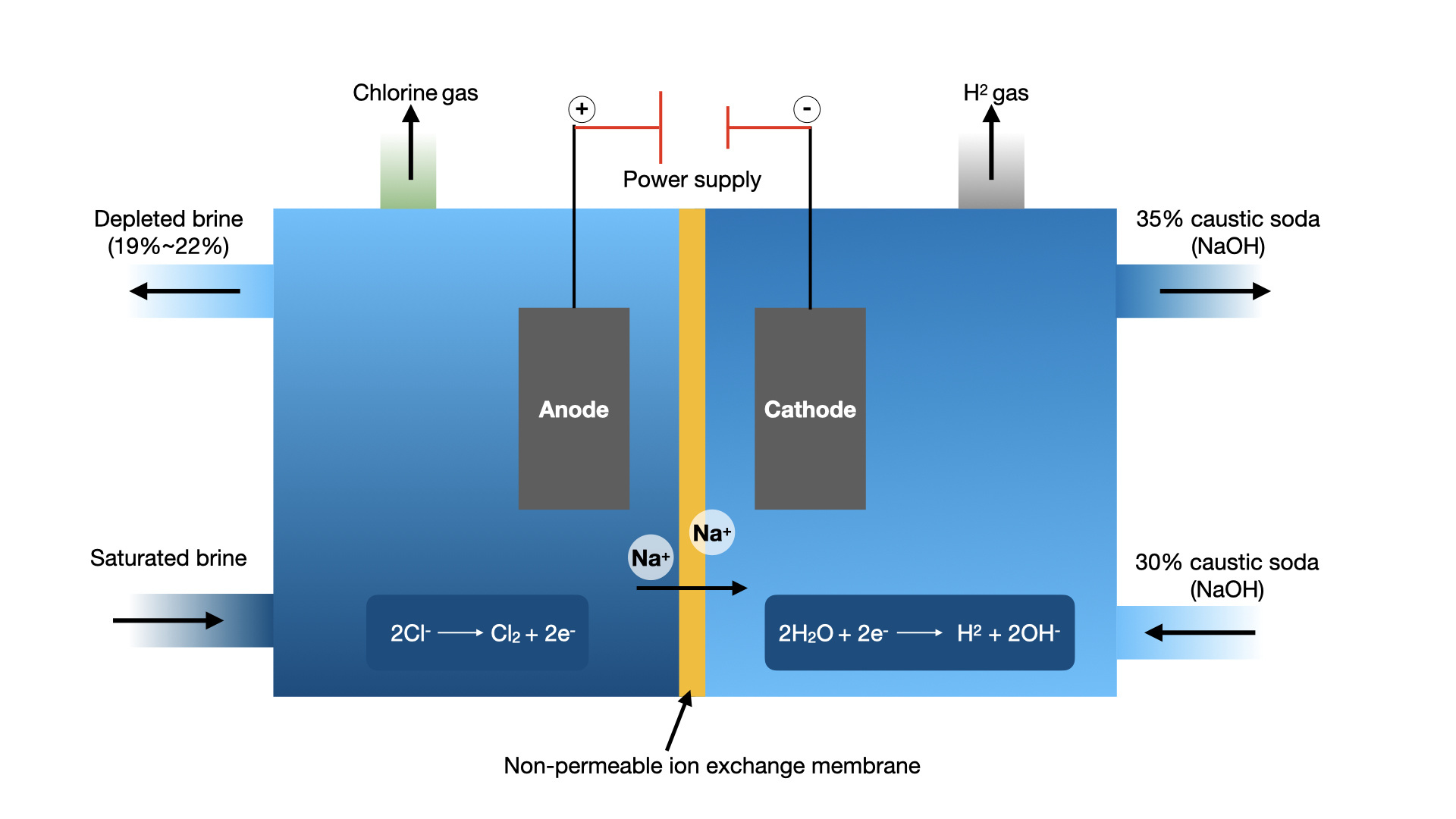

The electrolysis cell is the core component of our Membrane Electro-chlorination System, where a series of fundamental electrochemical processes take place, converting raw materials into valuable products. This controlled environment ensures the safe and efficient generation of sodium hypochlorite solution. Here's a more detailed breakdown of the electrolysis process:

* Brine Introduction: The process commences with the introduction of brine, a concentrated salt solution, into the anode compartment of the electrolysis cell. This brine serves as the source of chlorine production.

* Cathode Compartment: Simultaneously, a 30% caustic soda solution is introduced into the cathode compartment. This alkaline solution is essential for the production of sodium hydroxide (NaOH) and hydrogen (H2) gas.

* Membrane Separation: A specialized membrane, a critical element in the system, segregates the anode and cathode compartments. This membrane is highly selective, allowing the migration of specific ions while preventing the unwanted mixing of chemicals.

* Chlorine Generation: Within the anode compartment, chloride ions (Cl-) present in the brine undergo oxidation. This results in the release of chlorine gas (Cl2), which is collected and further processed.

* Hydroxide and Hydrogen Production: In the cathode compartment, hydroxide ions (OH-) are produced through the reduction of water (H2O). This process generates sodium hydroxide (NaOH) and hydrogen gas (H2).

* Efficient Separation: The membrane ensures that the chlorine and sodium hypochlorite produced in their respective compartments remain separated, preventing cross-contamination.

This well-orchestrated electrolysis process not only guarantees the production of sodium hypochlorite solution but also promotes safety, efficiency, and resource conservation. It exemplifies our commitment to delivering cutting-edge water treatment solutions to our valued customers.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

200kg

-

Size:

-

2*1.5*10 meter

-

Power:

-

depends on different model

-

Weight (KG):

-

200 kg

-

Brand:

-

Wiztech

-

Control:

-

Auto/Manual

-

Function:

-

Brine electro-chlorination

-

Concentration:

-

3%~15%

-

Electrode:

-

Pure titanium with coating

-

Salt requirement:

-

Food grade/ Industrial

-

Salt consumption:

-

1.5kg/ 1 kg chlorine

-

Electricity consumption:

-

4kw/ 1kg chlorine

-

Application:

-

water disinfection

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Wiztech

-

Material:

-

Plywood case

-

Weight:

-

200kg

-

Size:

-

2*1.5*10 meter

-

Power:

-

depends on different model

-

Weight (KG):

-

200 kg

-

Brand:

-

Wiztech

-

Control:

-

Auto/Manual

-

Function:

-

Brine electro-chlorination

-

Concentration:

-

3%~15%

-

Electrode:

-

Pure titanium with coating

-

Salt requirement:

-

Food grade/ Industrial

-

Salt consumption:

-

1.5kg/ 1 kg chlorine

-

Electricity consumption:

-

4kw/ 1kg chlorine

-

Application:

-

water disinfection

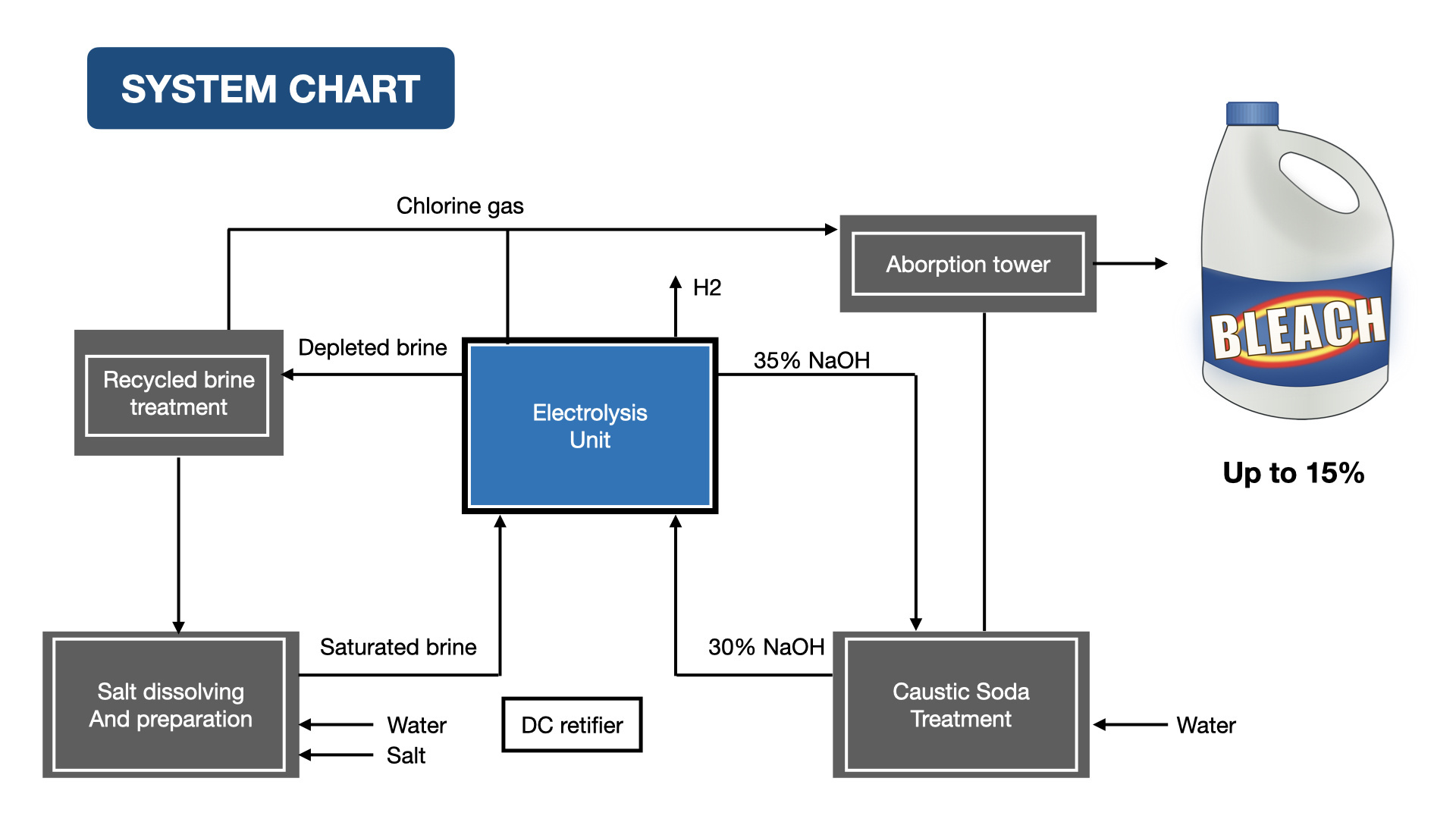

Product Overview

SODIUM HYPOCHLORITE PLANT

3% 5% 10% 12% NaClO Bleach Liquid Production Plant

It's a membrane electro-chlorination system that use salt, water, alkali as raw material to produce chlorine gas and form sodium hypochlorite solution ( Bleach liquid) which concentration from 3% up to 15%.

35% Sodium Hydroxide Liquid 50% Caustic Soda Liquid By Membrane Electrolysis Process Plant

Membrane electro-chlorination principal

MEMBRANE

The membrane is a perfluorosulfonic acid/carboxylic acid composite membrane. The transportation temperature is 2 to 50°C. Avoid contact with other items, drying, and wrinkles. Store it in a 2% NaHCO3 solution.

PRODUCT SPECIFICATIONS

|

Module

|

10% solution production per hour

|

Active chlorine concentration

|

|

WIZG-50L

|

50L

|

10%

|

|

WIZG-100L

|

100L

|

10%

|

|

WIZG-150L

|

150L

|

10%

|

|

WIZG-200L

|

200L

|

10%

|

|

WIZG-250L

|

250L

|

10%

|

|

WIZG-300L

|

300L

|

10%

|

|

WIZG-350L

|

350L

|

10%

|

|

WIZG-400L

|

400L

|

10%

|

|

WIZG-500L

|

500L

|

10%

|

|

WIZG-600L

|

600L

|

10%

|

|

WIZG-700L

|

700L

|

10%

|

Successful Project

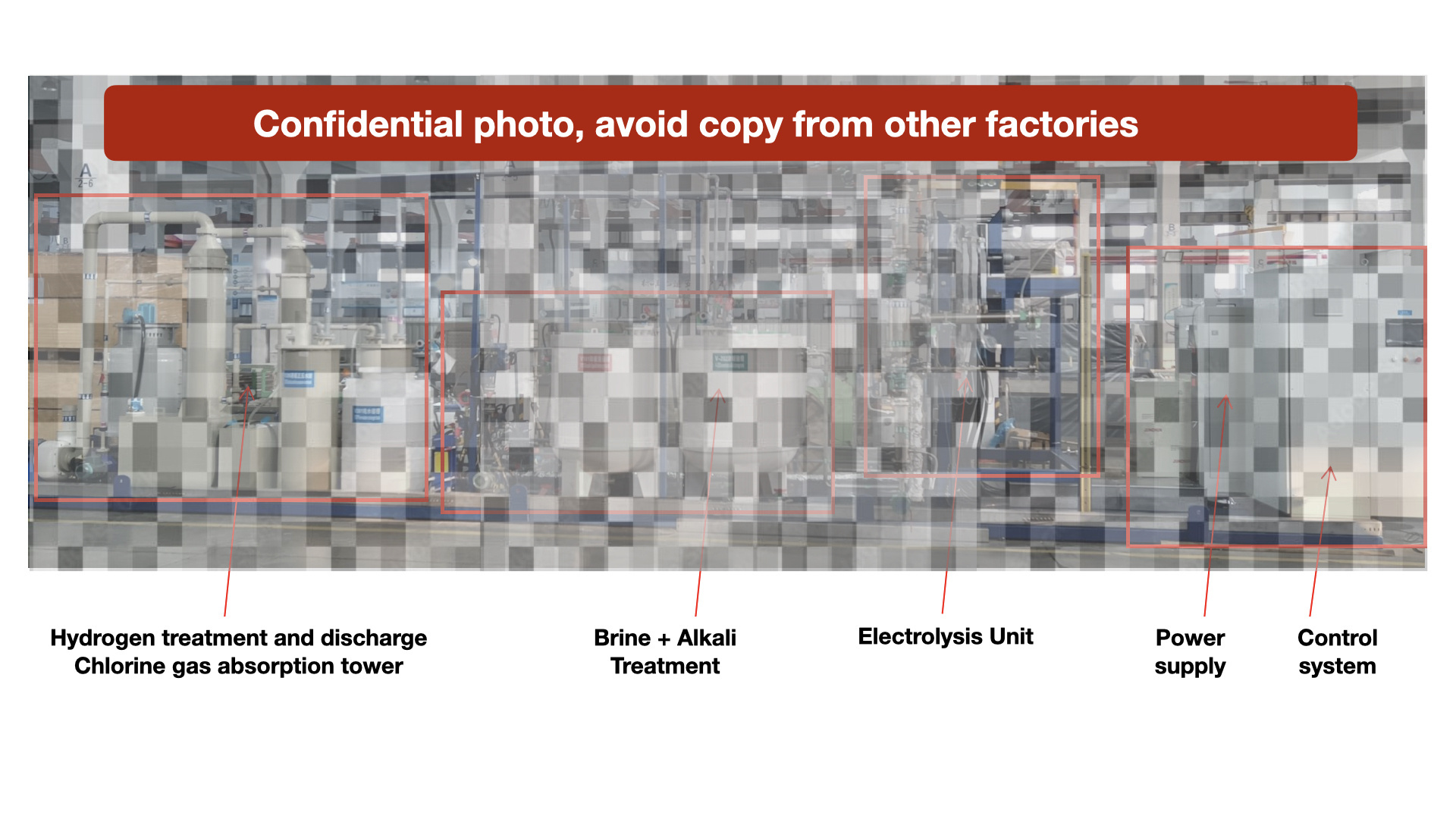

There are 2 factories copying our machine with our photos and technical data, so we don't displace here, please contact us for detail.

Hot Searches