- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1100*190

-

Weight:

-

2000 KG

-

Spare parts supply:

-

For whole year

-

Test&Installation:

-

Engineer Assigned

-

After-sale service:

-

For whole using life

-

Power(W):

-

7.5-90KW

-

Supply Ability:

-

30 Set/Sets per Month

-

Capacity:

-

3-50t/h

-

Port:

-

shanghai

-

Keyword:

-

gypsum grinding mill

-

Final size:

-

1.2-0.038mm

-

Max.Feed Size(mm):

-

50

Quick Details

-

Capacity(t/h):

-

0.5-340

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZENITH

-

Dimension(L*W*H):

-

1100*190

-

Weight:

-

2000 KG

-

Spare parts supply:

-

For whole year

-

Test&Installation:

-

Engineer Assigned

-

After-sale service:

-

For whole using life

-

Power(W):

-

7.5-90KW

-

Supply Ability:

-

30 Set/Sets per Month

-

Capacity:

-

3-50t/h

-

Port:

-

shanghai

-

Keyword:

-

gypsum grinding mill

-

Final size:

-

1.2-0.038mm

-

Max.Feed Size(mm):

-

50

Our gypsum grinding mill is specially designed for ultra-fine powder processing of gypsum in industries like wallboard, cement and fertilizer production.

Equipped with highly efficient classifier, our mill delivers gypsum powder below 2500 mesh with strong particle size control. It also features durable structure, stable performance and environmental protection.

Our ISO-certified grinding mill conforms to international production standards and quality certifications. It has maximum feed size of 25mm and adjustable production capacity of 0.5 to 8 tons per hour.

In addition to individual mills, we also provide complete powder grinding solutions including feeding machine, dust collector, packing machine and technical support.

As a professional gypsum processing equipment supplier, we deliver customized services from project consultation to installation, training and lifetime maintenance. Please contact us for your gypsum grinding needs.

Discover the power of gypsum grinding mill, the ultimate tool for grinding, pulverizing, and crushing limestone to perfection. Our high-quality grinding mill offers a wide range of benefits, including:

High efficiency: Our gypsum grinding mill is designed to deliver exceptional grinding performance while consuming less energy, resulting in significant cost savings.

Versatility: Our gypsum grinding mill is suitable for processing various materials, including limestone, dolomite, calcite, gypsum, and more. It can be used in a wide range of industries, such as cement, metallurgy, chemical engineering, and more.

Easy operation and maintenance: Our gypsum grinding mill is designed to be user-friendly, with a simple and intuitive control system. It is also easy to maintain, with minimal downtime and reduced maintenance costs.

High quality and reliability: Our gypsum grinding mill is manufactured using the highest quality materials and components, ensuring long-lasting performance and reliability.

Customizable solutions: We offer customized solutions tailored to your specific needs and requirements, ensuring that you get the perfect gypsum grinding mill for your application.

With our gypsum grinding mill, you can achieve superior grinding performance and take your business to the next level. Contact us today to learn more about our products and services.

|

|

Best Selling Rock Phosphate Grinding Mill Price Gypsum Grinding Mill

Product Features: Lower operational & maintenance costs, excellent environmental protection, better quality of finished products

Input Size:

0-50mm

|

Best Selling Rock Phosphate Grinding Mill Price Gypsum Grinding Mill introduction:

Best Selling Rock Phosphate Grinding Mill Price Gypsum Grinding Mill working principle:

After jaw crushers break large bulky materials to smaller ones, elevators work to send materials to the hopper. Then, by electromagnetic vibrating feeders, broken materials are evenly and quantitatively sent to the grinding chamber of gypsum grinding milll. After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure. Because materials have a certain content of moisture, heat generated during grinding may lead air evaporation or swell in the grinding chamber so that the amount of airflow increases sharply. Besides, if the feed port and joints of pipelines are not sealed well, external air may intrude the grinding mill and lead imbalance of airflow. So, ZENITH gypsum grinding mill arranges exhaust valves at the air outlet of the fan to induce redundant air into the bag filter. After purifying, the redundant air is discharged. This arrangement can achieve both the balance of airflow and the eco-friendly production.

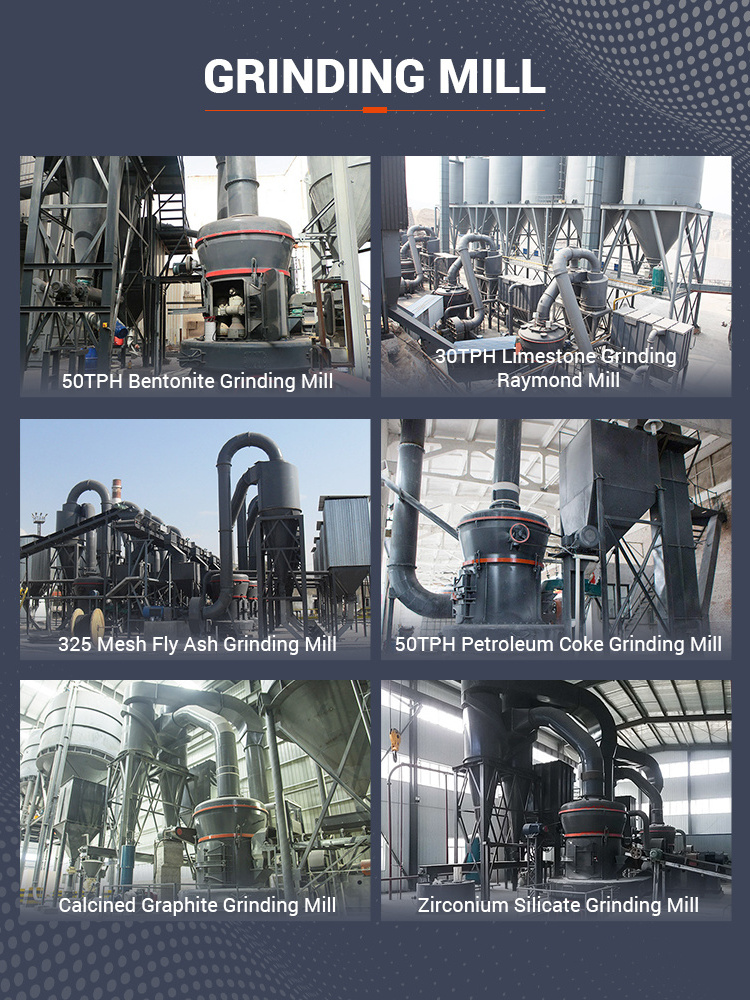

gypsum grinding mill photo:

Zenith Customer gypsum grinding mill

Certain chemical industry building material Co., Ltd., Zhejiang

This company mainly produces calcium carbonate powder, with finished product used in citric acid industry

It purchases a suit if gypsum grinding mill

Production Line Condition

Site: Zhejiang

Daily running: 22 hours

Raw material: Limestone, particle size 100-350mm, particle size into grinder<10mm

Finished product: calcium carbonate powder with 98% calcium content, particle size 150 screen meshes -200 screen meshes

Configuration: gypsum grinding mill complete equipment

Customer’s comment

Zenith company is very concerned about service condition at our site. What is even rarer is that it can absorb practical experience in customer use. It constantly improves details according to our real production conditions. As a result, this suit if MTW138’s gypsum grinding mill yield also exceeds expectance. Compared with our previously used equipment, the prominent merit is convenience and simplicity in repair and maintenance. Currently our company’s machines are developing to large scale. If new equipment needs to be increased, Zenith’s gypsum grinding mill equipment will still be the first choice.

-----Mr. Shen, factory director of factory in this building material company

Finished Products of Best Selling Rock Phosphate Grinding Mill Price Gypsum Grinding Mill:

Specifications of Best Selling Rock Phosphate Grinding Mill Price Gypsum Grinding Mill:

| Name & Model | MTW110 | MTW138 | MTW175 | MTW215 |

| Ring Roller Number(pcs) | 4 | 4 | 5 | 5 |

| Major diameter of roller(mm) | 360×190 | 460×240 | 520×280 | 640x 320 |

| Inner diameter of roller (mm) | 1100×190 | 1380×240 | 1750×280 | 2150x 320 |

| Revolving Speed(rmin) | 120 | 96 | 75 | 65 |

| Max.Feed Size(mm) | <30 | <35 | <40 | <50 |

| Final size(mm) |

1.6-0.045,

fineness can reach to 0.038 |

1.6-0.045,

fineness can reach to 0.038 |

1.6-0.045,

fineness can reach to 0.038 |

1.6-0.075,

fineness can reach to 0.038 |

| Capacity(th) | 3.5-10 | 6.5-15 | 13-20 | 30-45 |

| Overall dimension(mm) | 8625×7933×8642 | 10920×9470×10227 | 12275×9555×9916 | 14730x 10860x 10341 |

| Main unit motor | Model | Y280M-6 | Y315M-6 | Y355M2-8 |

| Power(kw) | 55 | 90 | 160 | 280 |

| Rotate Speed(rmin) | 980 | 990 | 740 | 740 |

|

Classifier speed regulating motor

(variable frequency motor) |

Model | Y132M-4 | Y180M-4 | Y200L-4 |

| Power(kw) | 7.5 | 18.5 | 30 | 90 |

| Rotate Speed(rmin) | 1440 | 1470 | 1470 | 1470 |

| Centrifugal induced draft fan motor | Model | Y250M-4 | Y315-4 | Y315L2-4 |

| Power(kw) | 55 | 110 | 200 | 315 |

| Rotate Speed(rmin) | 1480 | 1480 | 1480 | 1480 |

| Elevator | Bucket Model | TH210 | TH315 | TH315 |

| Motor Model | Y100L2-4 | Y112M-4 | Y112M-4 | Y160M-4 |

| Motor Power(kw) | 3 | 3 | 4 | 11 |

| Rotate Speed(rmin) | 1430 | 1430 | 1440 | 1440 |

| Jaw Crusher | Model | PE250×400 | PE250×750 | PE250×750 |

| Motor Model | Y180L-6 | Y200L2-6 | Y200L2-6 | Y315M2-6 |

| Power(kw) | 15 | 22 | 22 | 110 |

| Rotate Speed(rmin) | 970 | 970 | 970 | 990 |

| Magnetic Vibrating Feeder | Model | GZ2F | GZ3F | GZ4F |

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Zenith products have acquired :

Russian GOST Certificate

EU CE Cetificate

ISO Quality Management Certificate

China Good Enterprises

China Credit Example Certificate , etc.