- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SUNRISE

-

Voltage:

-

Customization

-

Dimension(L*W*H):

-

Customization

-

Weight:

-

500 KG

-

Features:

-

Energy Saving

-

Raw Material:

-

Sawdust Rise Husk

-

Product name:

-

Wood Sawdust Briquette Charcoal Making Machine

-

Finished Products:

-

Hexagon Biomass Wood Briquettes

-

Usage:

-

Extruding Fuel Briquettes

-

Suitable material:

-

Hard Wood Sawdust Rice Husk

-

Function:

-

Press Biomass Material

-

Aftersale service provided:

-

Online

-

Color:

-

Customised

-

Type:

-

Biomass Briquetting Plant

-

Package:

-

Wooden Case

Quick Details

-

Application:

-

Briquette Making Machine

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SUNRISE

-

Voltage:

-

Customization

-

Dimension(L*W*H):

-

Customization

-

Weight:

-

500 KG

-

Features:

-

Energy Saving

-

Raw Material:

-

Sawdust Rise Husk

-

Product name:

-

Wood Sawdust Briquette Charcoal Making Machine

-

Finished Products:

-

Hexagon Biomass Wood Briquettes

-

Usage:

-

Extruding Fuel Briquettes

-

Suitable material:

-

Hard Wood Sawdust Rice Husk

-

Function:

-

Press Biomass Material

-

Aftersale service provided:

-

Online

-

Color:

-

Customised

-

Type:

-

Biomass Briquetting Plant

-

Package:

-

Wooden Case

Products Description

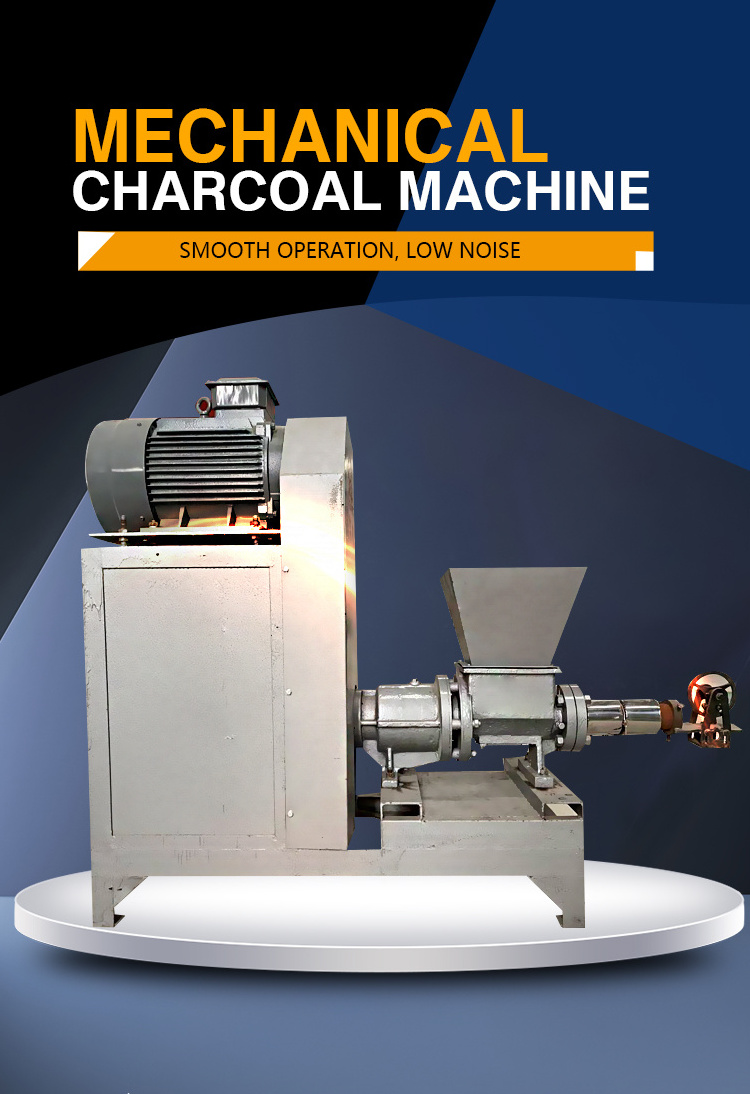

Small Biomass Charcoal Machine Wood Coal Sawdust Briquette Extruder Machine

Biomass briquette extruding machine:

This kind of machine is producing firewood bar ready for making charcoal bar.

Tree branches, leaves, sawdust, and other biomass materials, when crushed, can be used to make charcoal rods, which can replace traditional coal and are known as biomass charcoal,this a new type of fuel.

The production and processing procedure of a charcoal:

1.Crushing the biomass material with a crusher, and then controlling the moisture content through a dryer.

2.The material is conveyed to the molding machine by a belt conveyor or manually, and after pressing and forming, fire wood rod are obtained.

3.The fire wood rod is passed through the carbonization furnace to obtain the finished carbon rod.

4.The process from raw material to fuel involves the following steps: biomass material collection, crushing processing, conveying to the molding equipment, pressing, shaping, output, cooling, and transportation,Finally, it is used as fuel for small-scale boilers and biomass power plants.

|

Model

|

power/kw

|

Capacity /h

|

|

se18.5

|

18.5

|

230kg/h

|

|

se22

|

22

|

300kg/h

|

|

se30

|

30

|

450kg/h

|

FAQ

|

1.Are you manufacturer or trade company?

|

|

A:We are a professional manufacturer for producing biochar processing equipment and related machine(biochar, activated charcoal, carbon based fertilizer, and organic fertilizer) etc.

|

|

2.How should to do if I meet some trouble while using?

|

|

A:The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

|

|

3. Do you provide the installation service after ordering your machines?

|

|

A:As for the single machine, we provide the users instruction and operation video.

As for the production line,we provide the professional construction drawing,and arrange the engineer guide the user install the machines.Help the user train the skilled workers. |

|

4.Can we visit your factory to see some fertilizer plant with your machine?

|

|

A:We really give every customer a warm welcome to visit our factory,and we can take the customer to visit fertilizer plants with our equipment.

|

Hot Searches