- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xinli

-

Model Number:

-

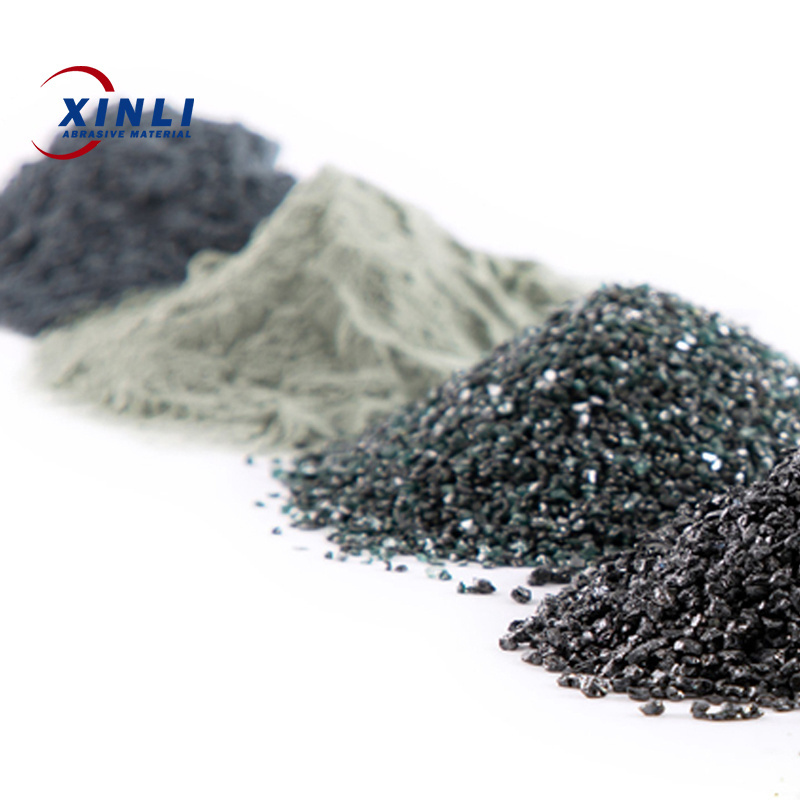

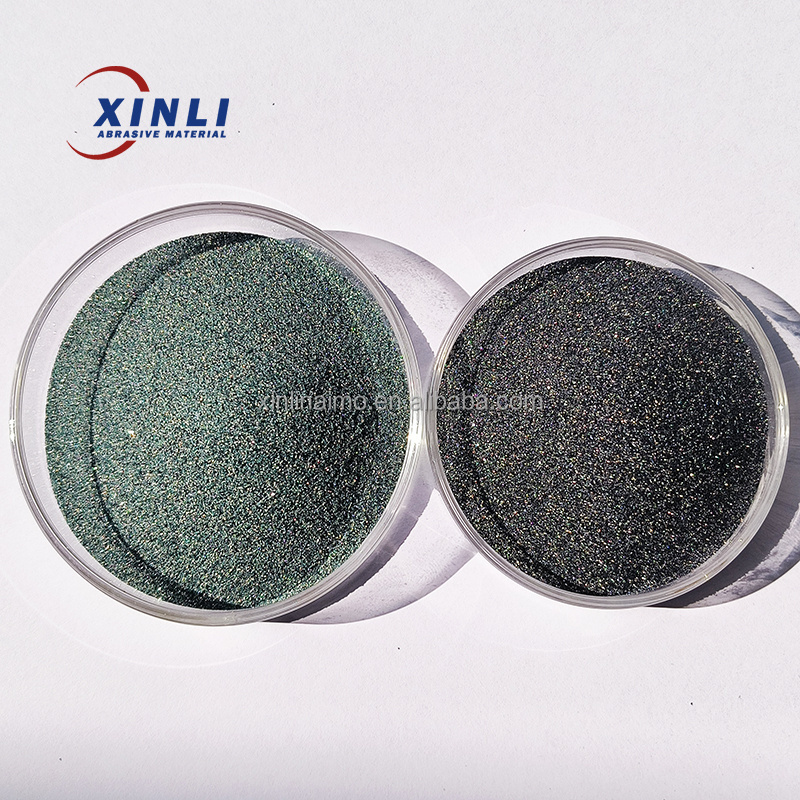

black silicon carbide

-

Use:

-

Sand blasting, polishing, resin bonded

-

Usage:

-

Sand blasting, polishing, resin bonded

-

Color:

-

Black

-

Material:

-

SiC

-

SiC Content:

-

98.5% Min

-

Bulk density:

-

1.45-1.56g/cm3

-

Ture density:

-

3.12 g/cm3

-

Crystalsystem:

-

Hexagonal

-

Micro Hardness:

-

HV3100-3280

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

abrasive

-

Abrasive Grain Sizes:

-

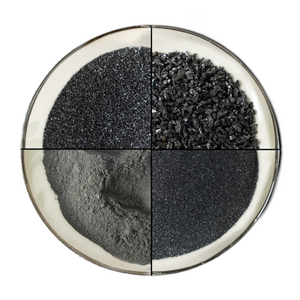

F240- F2000, Sic 12-2000#

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinli

-

Model Number:

-

black silicon carbide

-

Use:

-

Sand blasting, polishing, resin bonded

-

Usage:

-

Sand blasting, polishing, resin bonded

-

Color:

-

Black

-

Material:

-

SiC

-

SiC Content:

-

98.5% Min

-

Bulk density:

-

1.45-1.56g/cm3

-

Ture density:

-

3.12 g/cm3

-

Crystalsystem:

-

Hexagonal

-

Micro Hardness:

-

HV3100-3280

-

Certification:

-

ISO9001

Product Description

99% purity Nano sic silicon carbide powder 10-6000# Sic Black silica carbide and sandblasting Black silicon carbide sic powder

Because of the rarity of natural moissanite, most silicon carbide is synthetic. It is used as an abrasive, and more recently as a semiconductor and diamond simulant of gem quality. The simplest manufacturing process is to combine silica sand and carbon in an Acheson graphite electric resistance furnace at a high temperature, between 1,600 °C (2,910 °F) and 2,500 °C (4,530 °F). Fine SiO2 particles in plant material (e.g. rice husks) can be converted to SiC by heating in the excess carbon from the organic material. The silica fume, which is a byproduct of producing silicon metal and ferrosilicon alloys, also can be converted to SiC by heating with graphite at 1,500 °C (2,730 °F).

Manufacture Specification

|

Black Silicon Carbide Chemical Composition (%)

|

|

|

|

|||

|

Grit

|

Sic

|

F.C.

|

Fe2O3

|

|||

|

F12-F90

|

≥98.50

|

<0.20

|

≤0.60

|

|||

|

F100-F150

|

≥98.00

|

<0.30

|

≤0.80

|

|||

|

F180-F220

|

≥97.00

|

<0.30

|

≤1.20

|

|||

|

F230-F400

|

≥96.00

|

<0.40

|

≤1.20

|

|||

|

F500-F800

|

≥95.00

|

<0.40

|

≤1.20

|

|||

|

F1000-F1200

|

≥93.00

|

<0.50

|

≤1.20

|

|||

|

P12-P90

|

≥98.50

|

<0.20

|

≤0.60

|

|||

|

P100-P150

|

≥98.00

|

<0.30

|

≤0.80

|

|||

|

P180-P220

|

≥97.00

|

<0.30

|

≤1.20

|

|||

|

P230-P500

|

≥96.00

|

<0.40

|

≤1.20

|

|||

|

P600-P1500

|

≥95.00

|

<0.40

|

≤1.20

|

|||

|

P2000-P2500

|

≥93.00

|

<0.50

|

≤1.20

|

|||

|

Black Silicon Carbide Physical Index

|

|

|

|

|

|

|||||

|

Grits

|

Bulk Density

g/cm3 |

High Density

g/cm3 |

Grits

|

Bulk Density

g/cm3 |

High Density

g/cm3 |

|||||

|

F16 ~ F24

|

1.42~1.50

|

≥1.50

|

F100

|

1.36~1.45

|

≥1.45

|

|||||

|

F30 ~ F40

|

1.42~1.50

|

≥1.50

|

F120

|

1.34~1.43

|

≥1.43

|

|||||

|

F46 ~ F54

|

1.43~1.51

|

≥1.51

|

F150

|

1.32~1.41

|

≥1.41

|

|||||

|

F60 ~ F70

|

1.40~1.48

|

≥1.48

|

F180

|

1.31~1.40

|

≥1.40

|

|||||

|

F80

|

1.38~1.46

|

≥1.46

|

F220

|

1.31~1.40

|

≥1.40

|

|||||

|

F90

|

1.38~1.45

|

≥1.45

|

|

|

|

|||||

Black Silicon Carbide Size Available

F12-F1200, P12-P2500

0-1mm, 1-3mm, 6/10, 10/18, 200mesh, 325mesh

Other special specifications could be supplied on request.

F12-F1200, P12-P2500

0-1mm, 1-3mm, 6/10, 10/18, 200mesh, 325mesh

Other special specifications could be supplied on request.

Best Selling

Applications

Black Silicon Carbide Applications

For abrasive: Lapping, Polishing , Coatings, Grinding , Pressure blasting.

For refractory: Refractory media for casting or metallurgical linings ,Technical Ceramics.

For new-type application: Heat exchangers ,Semiconductor process equipment , Liquid filtration.

For abrasive: Lapping, Polishing , Coatings, Grinding , Pressure blasting.

For refractory: Refractory media for casting or metallurgical linings ,Technical Ceramics.

For new-type application: Heat exchangers ,Semiconductor process equipment , Liquid filtration.

Packing and Delivery

Black Silicon Carbide Packing

1. 25kg woven bag, 40 woven bags/jumbo bag.

2. 25kg woven bag, 40 woven bags/pallet

3. 25kg paper bag, 40 paper bags/pallet

4. 25kg paper bag, 40 paper bags/paper box

1. 25kg woven bag, 40 woven bags/jumbo bag.

2. 25kg woven bag, 40 woven bags/pallet

3. 25kg paper bag, 40 paper bags/pallet

4. 25kg paper bag, 40 paper bags/paper box

Company Introduction

Zhengzhou Xinli Wear-resistant Materials Co. Ltd.

Founded in 1996, Zhengzhou Xinli Wear-resistant Materials Co. Ltd. Is a professional integrative enterprise specializing in R&D, producing, and selling various wear-resistant materials. Such as white fused alumina, white corundum powder, alumina powder, white aluminum oxide powder, green silicon carbide powder, brown fused alumina, brown corundum powder and other wear-resistant materials. With about 25 years experiences, Zhengzhou Xinli has become the first enterprise that achieves the original crystal granularity to standard 0.3μm, can gain the effect of metal mirror polishing. Xinli Wear-resistant Materials has complete inspection equipment and quality control system, and obtained ISO9001:2015 quality management system certification.

FAQ

Q: What is your delivery time?

A: Usually, the delivery time for 10 tons is 7 days, 10-20 tons is 15 days, above 20 tons is 20 days.

Q: What is your MOQ?

A: The MOQ is 1000kg.

Q: What is your payment terms?

A: T/T, Irrevocable L/C at sight

Q: Do you have discount for big orders?

A: Yes, definitely have. Please contact for detail information.

Q: Do you have after-sales service?

A: Yes, 24 hours customer service will wait for your contacting.

A: Usually, the delivery time for 10 tons is 7 days, 10-20 tons is 15 days, above 20 tons is 20 days.

Q: What is your MOQ?

A: The MOQ is 1000kg.

Q: What is your payment terms?

A: T/T, Irrevocable L/C at sight

Q: Do you have discount for big orders?

A: Yes, definitely have. Please contact for detail information.

Q: Do you have after-sales service?

A: Yes, 24 hours customer service will wait for your contacting.

Hot Searches