Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Guangdong, China

-

Usage:

-

CPU, GPU, LED

-

Brand Name:

-

KUAYUE

-

Model Number:

-

ODM

-

Type:

-

Liquid Glue

-

Item:

-

Thermal Conductivity Silicone Grease

-

Material:

-

silicone oil,metallic oxide and thermal conductive fillers

-

Color:

-

grey /white

-

Continuous use Temp:

-

-30~150

-

Thermal conductivity:

-

1~5w

-

Shelf life:

-

24 Months

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

Silicone Sealant

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Guangdong, China

-

Usage:

-

CPU, GPU, LED

-

Brand Name:

-

KUAYUE

-

Model Number:

-

ODM

-

Type:

-

Liquid Glue

-

Item:

-

Thermal Conductivity Silicone Grease

-

Material:

-

silicone oil,metallic oxide and thermal conductive fillers

-

Color:

-

grey /white

-

Continuous use Temp:

-

-30~150

-

Thermal conductivity:

-

1~5w

-

Shelf life:

-

24 Months

Thermal insulation Grease Conductive Silicone Paste Cooling Cooler Heatsink For CPU PC

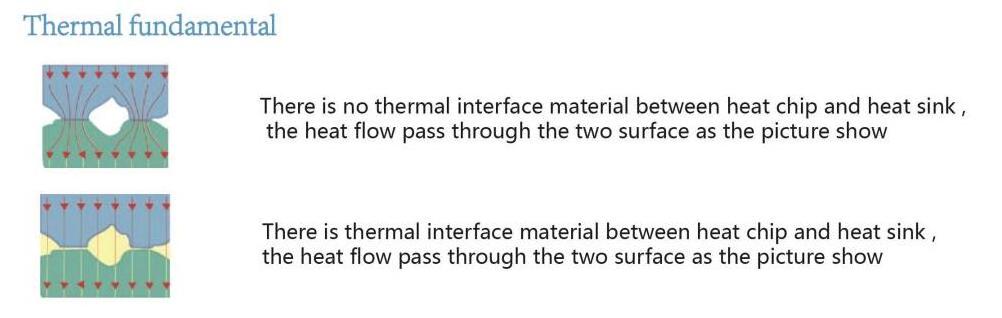

HC Z series thermal conductive grease is a kind of thermal conductive composite with grease-state , base silicone epoxy as main raw material, add heat-resisting materials with good performance of thermal conductivity. This material can effectively reduce thermal resistance on interface between heat sink and heat generator. HCZ series thermal conductive materials have the feature of low oil separation , high and low temperature change resistance, water proofing, aging resistance, have good performance with electric insulation, thermal conductivity. The materials can keep the humid grease-state on the interface for a long term at -40 to 200 ℃.

HCZ thermal conductive grease product data

| Test items | HCZ100 | HCZ150 | HCZ200 | HCZ300 | Unit | Test method |

| content | silicone oil,metallic oxide and thermal conductive fillers | ——— | ——— | |||

| form | paste | paste | paste | paste | ——— | Visual |

| color | white | white | gray | yellow | ——— | Visual |

| viscosity | 45000 | 50000 | 50000 | 50000 | cps | NDJ-4 |

| density | 2.1 | 2.3 | 2.5 | 2.8 | g/cm3 | ASTM D792 |

| Continuous use Temp | -30~150 | -30~150 | -30~150 | -30~150 | ℃ | EN344 |

| volatility | <1 | <1 | <0.5 | <0.5 | % | 120℃,4hr |

| Oil Separation | <1 | <1 | <1 | <1 | % | 120℃,4hr |

| thermal impedance | 0.155 | 0.135 | 0.105 | 0.083 | ℃.in2/W | EN344 |

| Thermal conductivity | 1 | 2 | 3 | W/m.k | ASTM D5470 | |

1. Good performance with thermal conductivity;

2.Low thermal resistance and oil separation;

3.Excellent performance with electric insulation;

4.high and low temperature change resistance;

5.water proofing, aging resistance;

6.Moisture-proof,anti-corrosion,Reliability;

7.Moist interface reduce thermal impedance;

8.make for the effect of thermal conductivity;