- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

CNC hydraulic folding machine

-

Color:

-

white and blue CNC hydraulic folding machine

-

Type:

-

Hydraulic Pan Box Brake

-

Folding Materials:

-

Q235 carbon steel,GI,CR,SS

-

Use:

-

metal plate processing

-

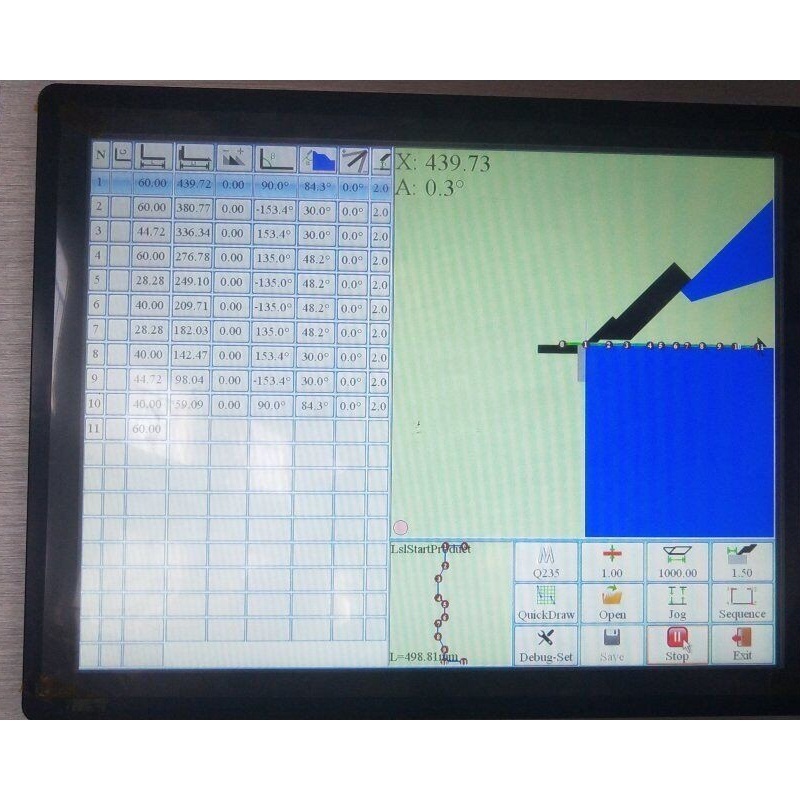

control system:

-

button

-

Folding Width:

-

1320,2500,3200,4000,6000mm

-

Application:

-

steel sheet bending/folding

-

Raw Material:

-

Sheet / Plate Rolling

-

Certification:

-

ISO 9001:2000

Quick Details

-

Bending Length(mm):

-

3200 mm

-

Place of Origin:

-

Jiangsu, China

-

Weight (KG):

-

3000

-

Product name:

-

CNC hydraulic folding machine

-

Color:

-

white and blue CNC hydraulic folding machine

-

Type:

-

Hydraulic Pan Box Brake

-

Folding Materials:

-

Q235 carbon steel,GI,CR,SS

-

Use:

-

metal plate processing

-

control system:

-

button

-

Folding Width:

-

1320,2500,3200,4000,6000mm

-

Application:

-

steel sheet bending/folding

-

Raw Material:

-

Sheet / Plate Rolling

-

Certification:

-

ISO 9001:2000

CNC Hydraulic Aluminium Sheet Metal Box And Pan brake Folder Automatic Pan And Box Folding Machine

Product Description

- Hydraulic clamp and unclamp from foot switch, this allows one man to operate machine and hold material in both hands; Clamping is limited to 10mm increments for safety. Unclamp from foot switch.

- Rapid head adjustment allows easy change different size material, by moving the handles, Adjustable to suit special jobs.

- Fingers clamp blade are high carbon steel, Apron blade high tensile steel.

- Electrics low 24 volts foot switch. Overload protected.

- Clamping provided by large rams, Oil delivered to rams through steel pipes this is to minimize expansion of hydraulic hose when working at full capacity.

- Unclamp is controlled, to allow the operator to regulate the open height.

- Bed head and apron are unique design, to provide maximum strength. To give a straight fold.

- Automatic and manual control. In auto cycle after clamping start auto a[rpm will come up to angle set, then apron will go down and the head will unclamp to amount set by operator.

- Electric components is.SIEMENS.

Technical parameter

| Model | Max. bending thickness(mm) | Max. bending width(mm) | Bending angel(degree) | Max open height(mm) | Main motor(kw) | Size (mm) |

| W67Y/K-2X2500 | 2 | 2500 | 0-120 | 110 | 2.2 | 3300*850*1550 |

| W67Y/K-2X3200 | 2 | 3200 | 0-120 | 110 | 2.2 | 4100*1550*1550 |

| W67Y/K-3X2500 | 3 | 2500 | 0-120 | 110 | 4 | 3700*1640*1650 |

| W67Y/K-3X3200 | 3 | 3200 | 0-120 | 110 | 4 | 4400*1640*1650 |

| W67Y/K-3X4000 | 3 | 4000 | 0-120 | 110 | 7.5 | 5200*1640*1650 |

| W67Y/K-3X6000 | 3 | 6000 | 0-120 | 110 | 7.5 | 6200*1640*1650 |

| W67Y/K-4X2500 | 4 | 2500 | 0-120 | 110 | 4 | 3750*1640*1650 |

| W67Y/K-4X3200 | 4 | 3200 | 0-120 | 110 | 4 | 4450*1640*1650 |

| W67Y/K-4X4000 | 4 | 4000 | 0-120 | 110 | 7.5 | 5250*1640*1650 |

| W67Y/K-4X6000 | 4 | 6000 | 0-120 | 110 | 7.5 | 6250*1640*1650 |

| W67Y/K-5X2500 | 5 | 2500 | 0-120 | 110 | 5.5 | 3800*1640*1650 |

| W67Y/K-5X3200 | 5 | 3200 | 0-120 | 110 | 5.5 | 4500*1640*1650 |

| W67Y/K-5X4000 | 5 | 4000 | 0-120 | 110 | 11 | 5300*1640*1650 |

| W67Y/K-5X6000 | 5 | 6000 | 0-120 | 110 | 11 | 6300*1640*1650 |

| W67Y/K-6X2500 | 6 | 2500 | 0-120 | 110 | 11 | 3900*1640*1650 |

| W67Y/K-6X3200 | 6 | 3200 | 0-120 | 110 | 11 | 4600*1640*1650 |

| W67Y/K-6X4000 | 6 | 4000 | 0-120 | 110 | 15 | 5400*1640*1650 |

| W67Y/K-6X6000 | 6 | 6000 | 0-120 | 110 | 15 | 6400*1640*1650 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.